Preparation method of CSiNB-based multi-element integrated fiber felt material

A fiber felt and carbon fiber felt technology, which is applied in the field of fiber felt material preparation, can solve the problems of high cost, complicated process, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

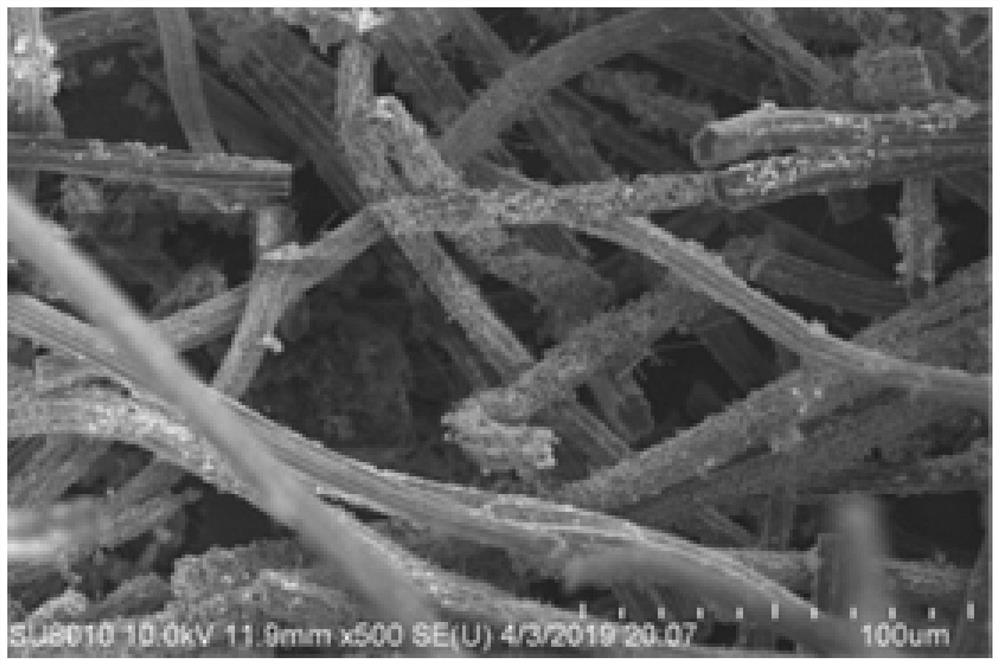

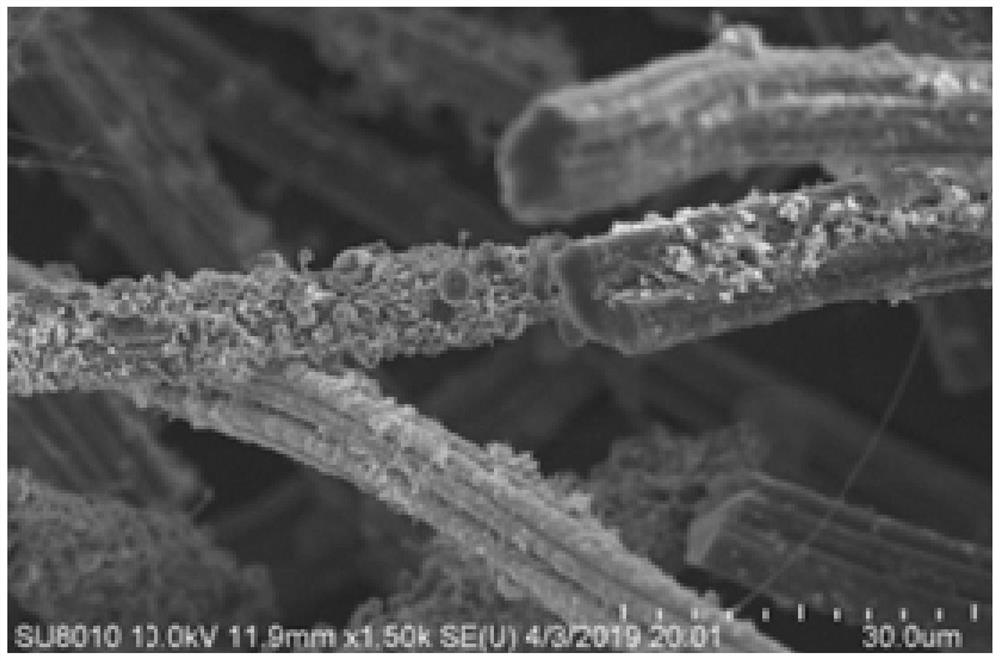

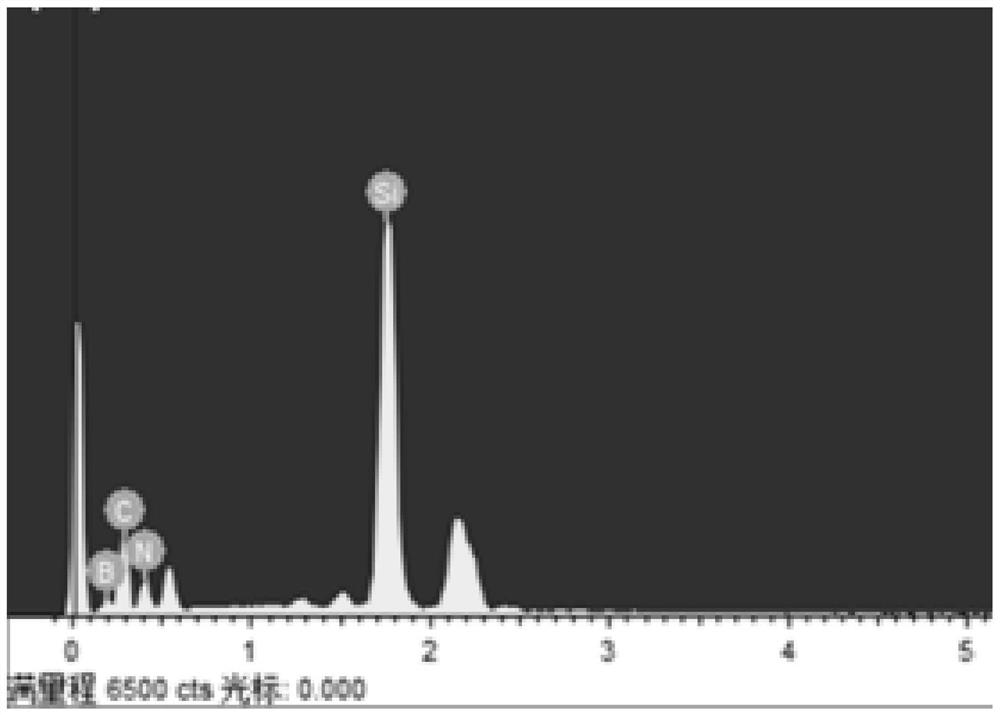

[0022] Embodiment 1: In this embodiment, a method for preparing a CSiNB-based multi-component integrated fiber felt material is completed according to the following steps:

[0023] 1. Activation treatment of carbon fiber felt:

[0024] Immerse the carbon fiber felt in an aqueous solution of inorganic salt ions, and activate it for 0.5h to 6h at a temperature of 20°C to 80°C to obtain an activated carbon fiber felt;

[0025] The mass percent of the inorganic salt ion aqueous solution is 1% to 10%;

[0026] Second, perfusion boron powder:

[0027] Immerse the activated carbon fiber felt in the boron powder dispersion liquid, and ultrasonically disperse it for 30 minutes to 60 minutes under the condition of ultrasonic power of 35W to 50W, or perform perfusion treatment for 24h to 48h under vacuum conditions to obtain a carbon fiber felt impregnated with boron powder ;

[0028] Described boron powder dispersion liquid is the mixed liquid of boron powder and alcohol, and the vol...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the carbon fiber felt described in step one has a unit mass of 200g / m 2 ~800g / m 2 carbon fiber mat; the thickness of the carbon fiber mat described in step 1 is 3 mm to 10 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the inorganic salt ion aqueous solution described in step one is sodium chloride aqueous solution, calcium chloride aqueous solution, sodium fluoride aqueous solution and calcium fluoride One or a mixture of several of them in the aqueous solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com