Automatic destackingand stacking system

An automatic and stacking technology, applied in the field of automatic palletizing tray system, can solve the problems of inapplicability to cigarette production enterprises, inaccurate spatial coordinates, high installation and maintenance costs, etc., to reduce labor intensity and improve management methods , Reduce the effect of on-site production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

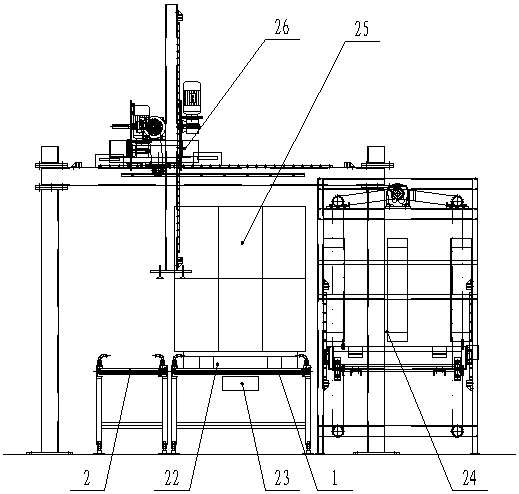

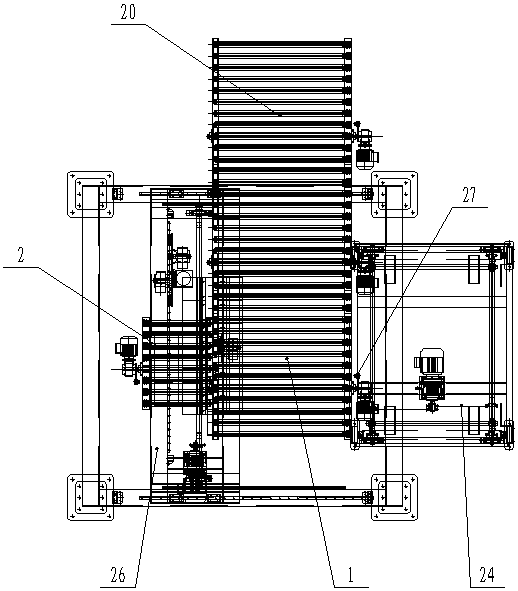

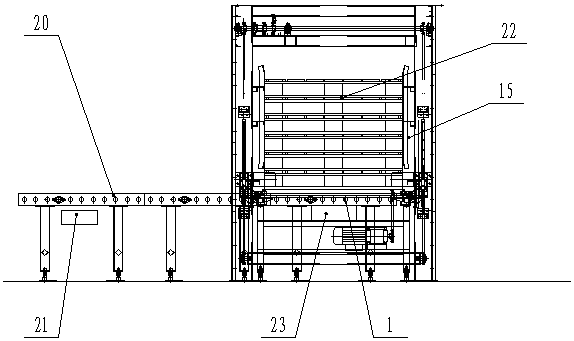

[0035] like Figure 1 to Figure 3 As shown, the present invention comprises a case stack roller conveyor and a single case roller conveyor positioned at one side of the case stack roller conveyor, and the case stack buffer station 20 is set at the upstream of the case stack roller conveyor, and the case stack The downstream of the roller conveyor is provided with a destacking station 1, and the case stack roller conveyor is provided with a positioning device 27 that makes the case stacks positioned at the destacking station.

[0036] The position corresponding to the single-case roller conveyor and the unstacking station is set as single-case placement station 2, and the single carton after destacking is sent to the production line by the single-case roller conveyor.

[0037] The positioning device 27 includes a photoelectric sensor or a proximity sensor arranged correspondingly to the unstacking station 1. The photoelectric sensor or proximity sensor is installed on the frame...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that the positioning device includes a stopper installed on the downstream edge of the unstacking station 1, the stopper is fixedly installed on the frame of the roller conveyor, and the height of the stopper is the same as Corresponding to the pallet; when the box stack is placed on the pallet and transported to the unstacking station by the box stack roller conveyor, the pallet is stopped by the stopper to realize positioning.

[0062] A travel switch is also arranged on the stopper. When the pallet is stopped by the stopper, the travel switch is triggered by the pallet, and the travel switch sends a signal to control the case stack roller conveyor to stop rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com