Automatic destacking and stacking method based on RFID

An automatic and stacking technology, applied in the field of automatic depalletizing pallets based on RFID, can solve the problems of not being well suited for standardized depalletizing pallets, low efficiency of depalletizing pallets, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

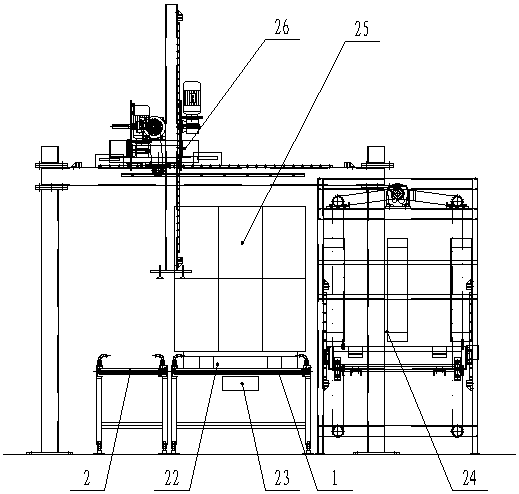

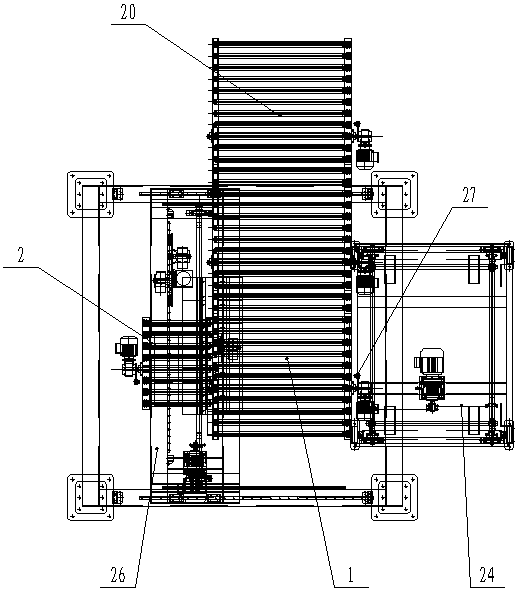

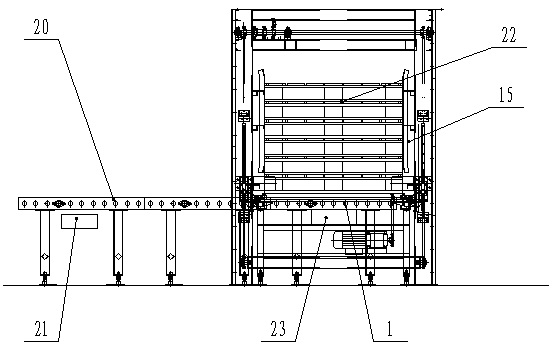

[0033] Such as Figure 1 to Figure 3 As shown, a kind of RFID-based automatic palletizing tray method of the present invention comprises the following steps:

[0034] (1) Storage: Install RFID electronic tags at the bottom of the pallet 22 of the loading box stack 25, and write the information of the batch of materials into the RFID electronic tag before storage, and the box stack 25 is coded on the corresponding pallet 22 according to the prescribed form restocking;

[0035] (2) Out of the warehouse: the forklift moves the box stack 25 in the warehouse and places it on the box stack buffer station 20. The box stack buffer station 20 is located upstream of the unstacking station 1 and is transported and connected by the box stack roller conveyor. ; The RFID reader 21 below the case stack buffer station 20 reads the product bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com