Patents

Literature

58results about How to "Achieve sales" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

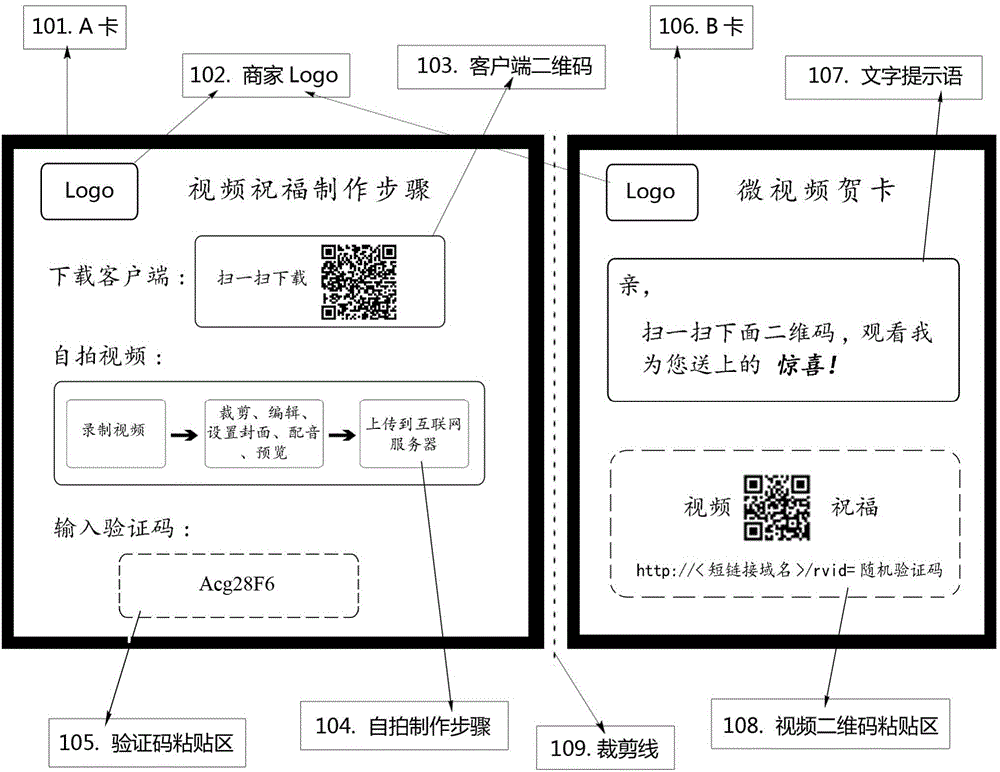

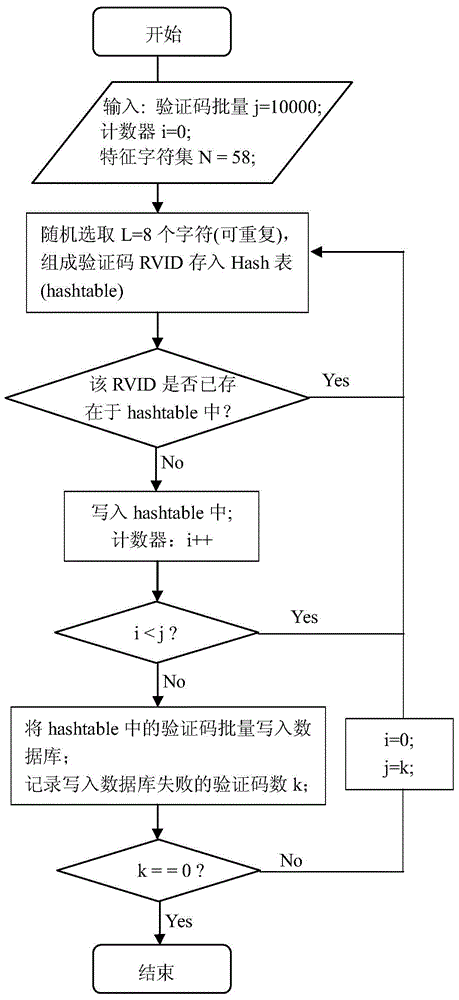

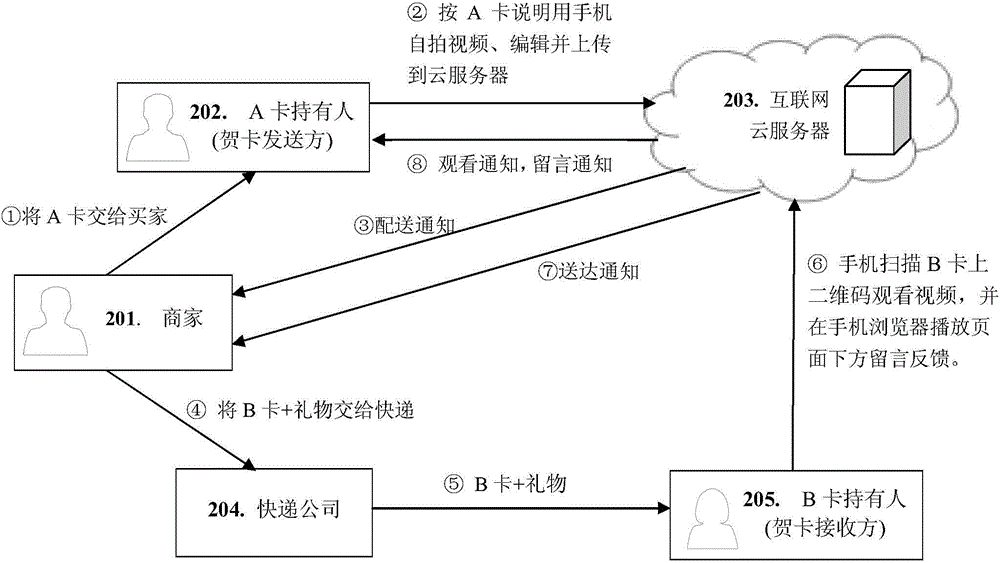

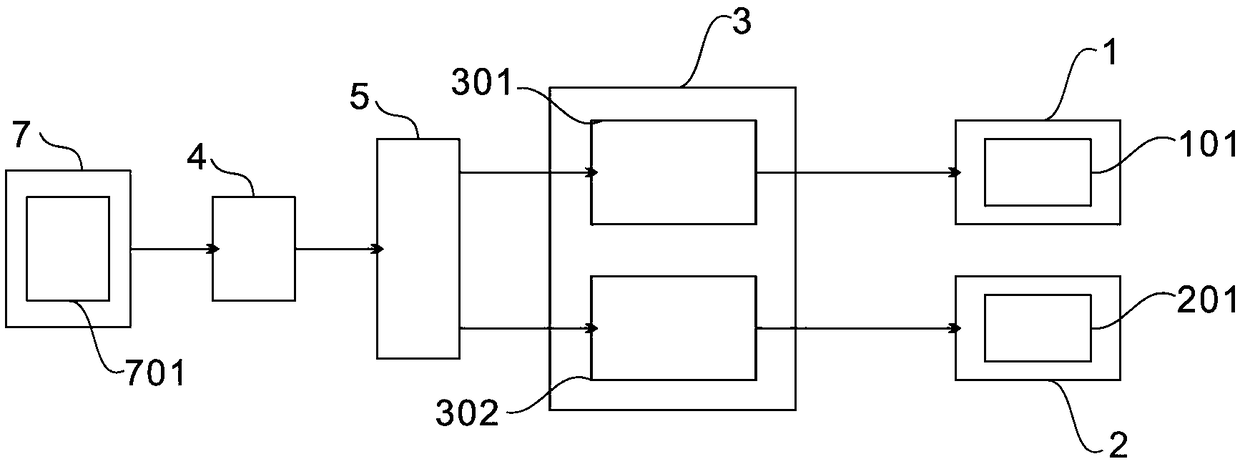

Interactive video greeting card

ActiveCN104951826AEasy to manufactureEasy to watchSelective content distributionRecord carriers used with machinesComputer hardwarePersonalization

Disclosed in the invention is an interactive video greeting card. A sender guides and operates a smart phone to make and share personalized video blessing information based on simple steps on a greeting card. A receiver uses a smart phone to scan a two-dimensional code on the greeting card to watch the video made by the sender rapidly without the need to install software and bidirectional interactive communication with the sender also can be realized. According to the greeting card, advantages of the traditional papery greeting card and the internet technology are effective integrated, so that defects that effects of vividness, customization at any time, and bidirectional interaction can not be realized by using the papery greeting card and offline synchronous distribution and surprise creating of the single electronic greeting card and the real gifts can not be realized can be overcome. Meanwhile, a consumer can be automatically brought into the client relation management unit of a merchant by consuming the greeting card once. Therefore, the provided greeting card has the broad application prospects and the great commercial value.

Owner:NANJING WEITEXI NETWORK SCI & TECH

Method for recycling titanium, silicon, aluminum, calcium and magnesium from titaniferous blast furnace slag by multistage acid leaching

InactiveCN103952567ALow costQuality improvementRecycling and recovery technologiesProcess efficiency improvementSlagManganese

The invention discloses a method for recycling titanium, silicon, aluminum, calcium and magnesium from titaniferous blast furnace slag by multistage acid leaching. The titaniferous blast furnace slag is especially titaniferous blast furnace slag obtained by carrying out iron making on vanadium titanomagnetite in Panzhihua regions. The method comprises the following steps: carrying out acid leaching (especially multistage acid leaching) on furnace slag to obtain an acid leaching solution and white carbon black; and carrying out an extraction technique on the acid leaching solution to obtain titanium, aluminum, calcium, magnesium, manganese, iron, chromium, vanadium and other useful metals. On the premise of recycling resources, the method implements cyclic utilization of waste (using waste of one technique as a raw material of another technique), eliminates waste discharge, obviously lowers the cost and enhances the recycling efficiency.

Owner:衡阳市金铭环境科技有限公司

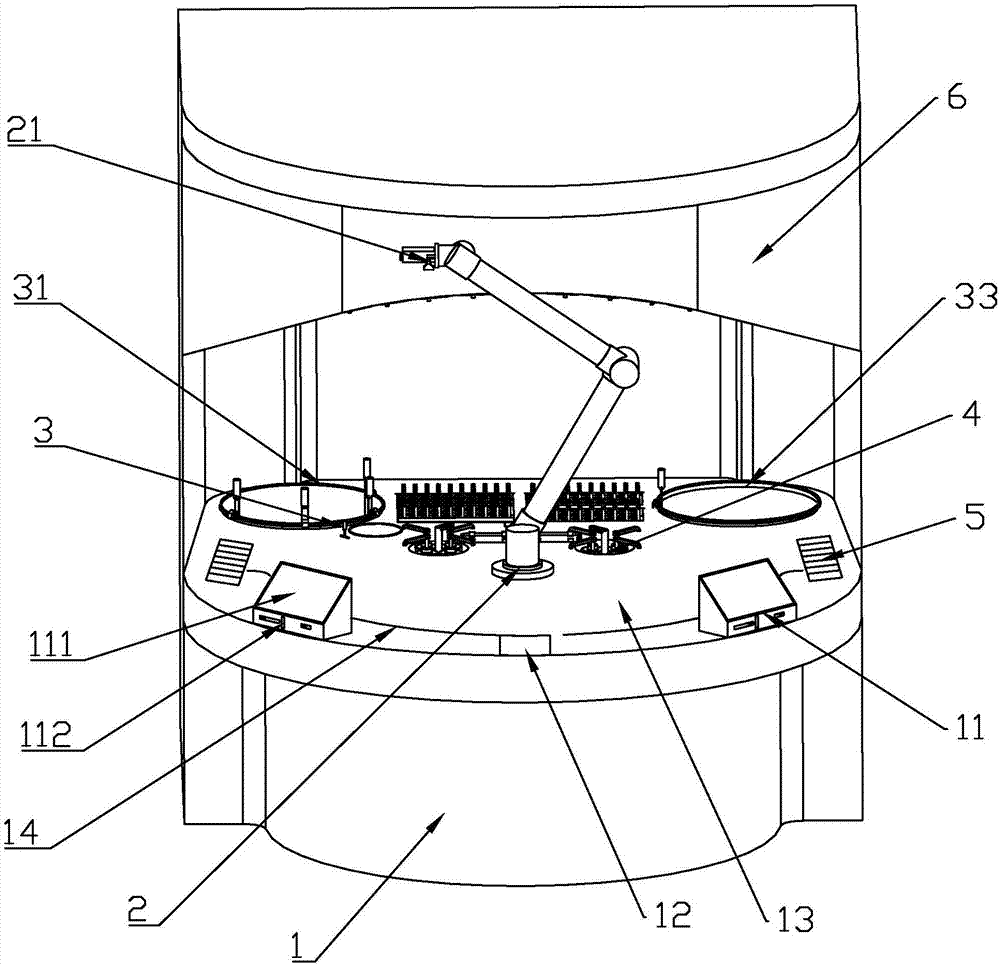

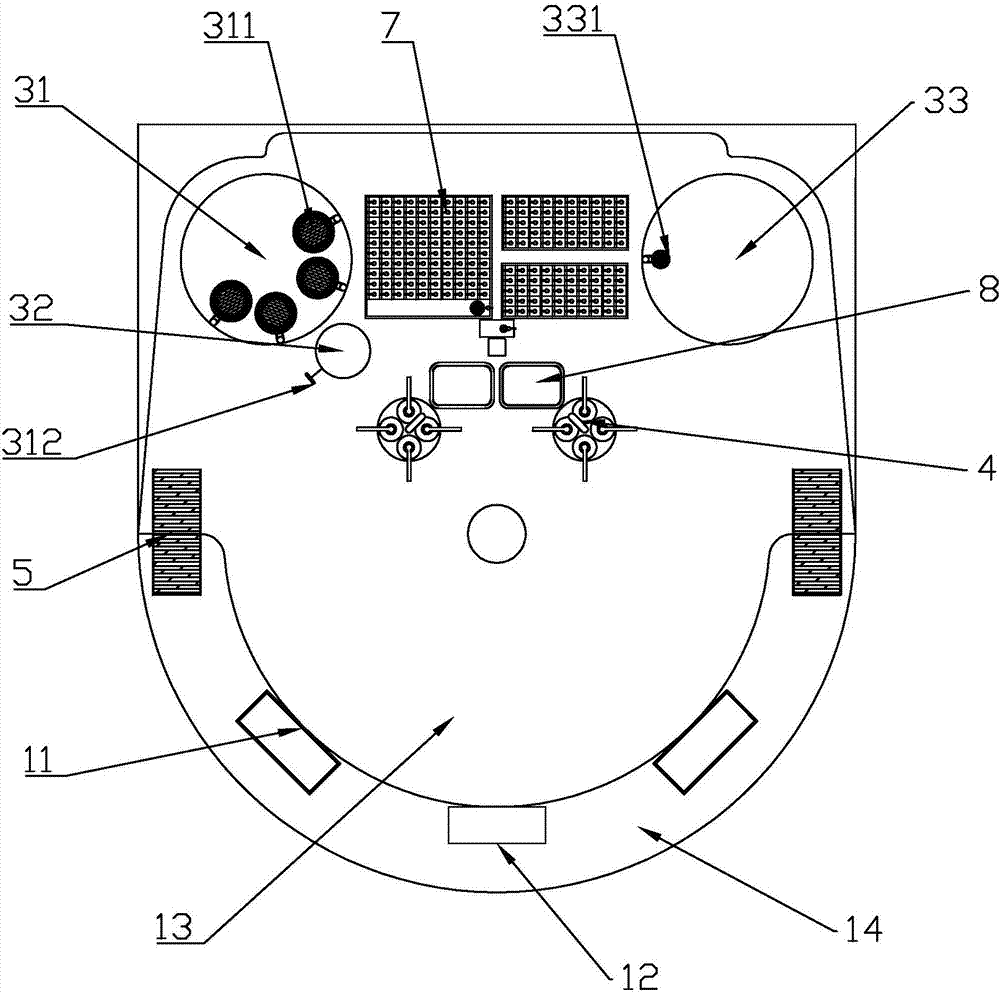

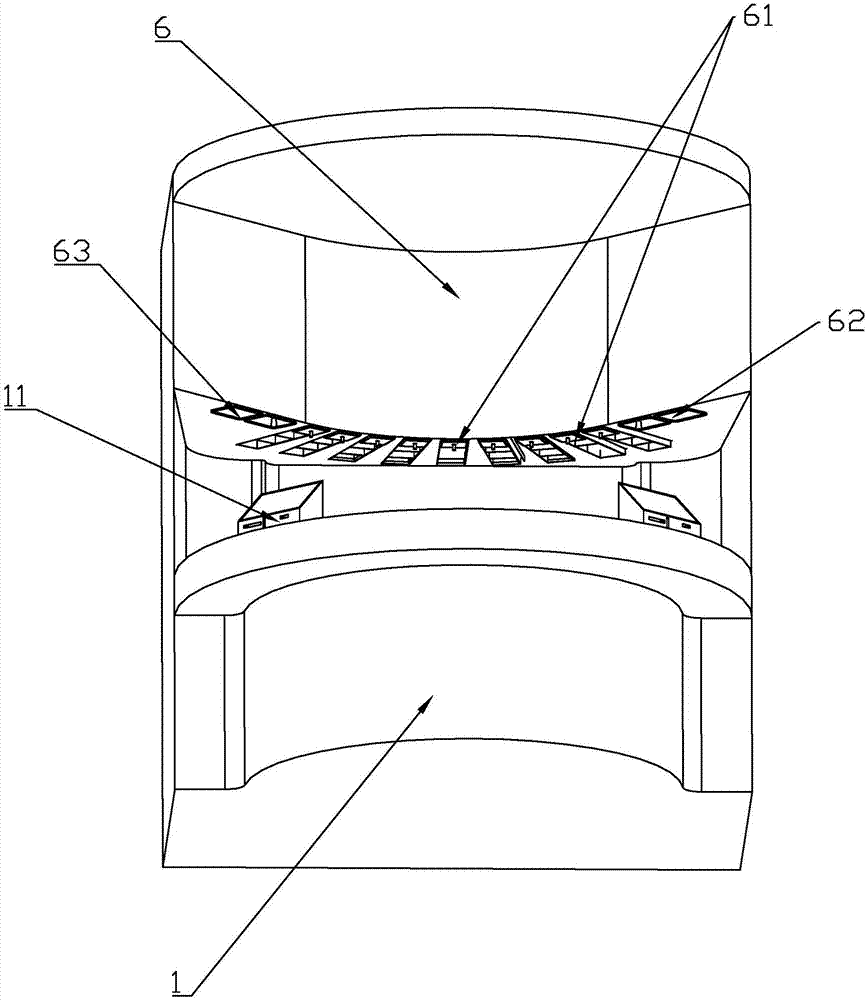

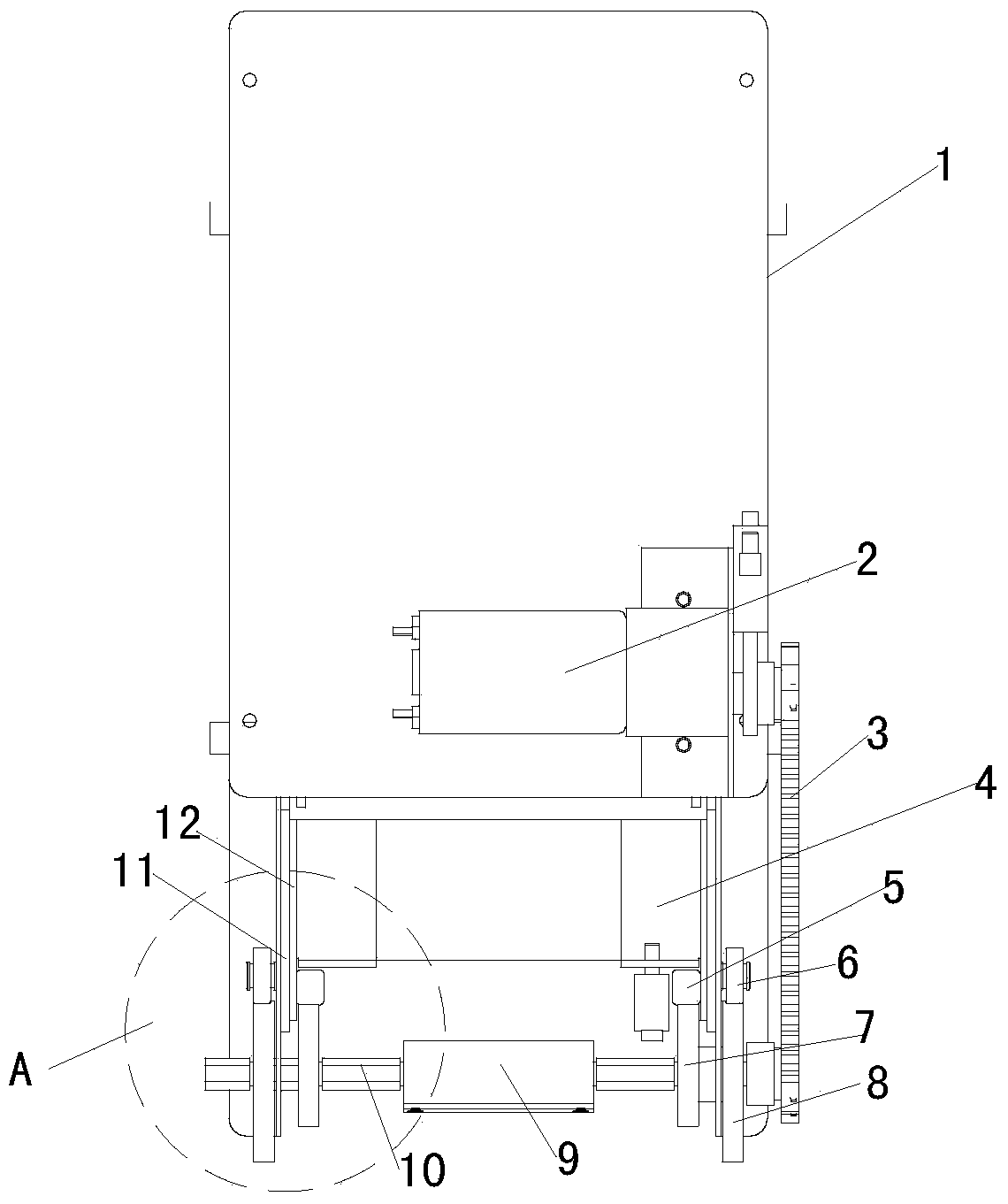

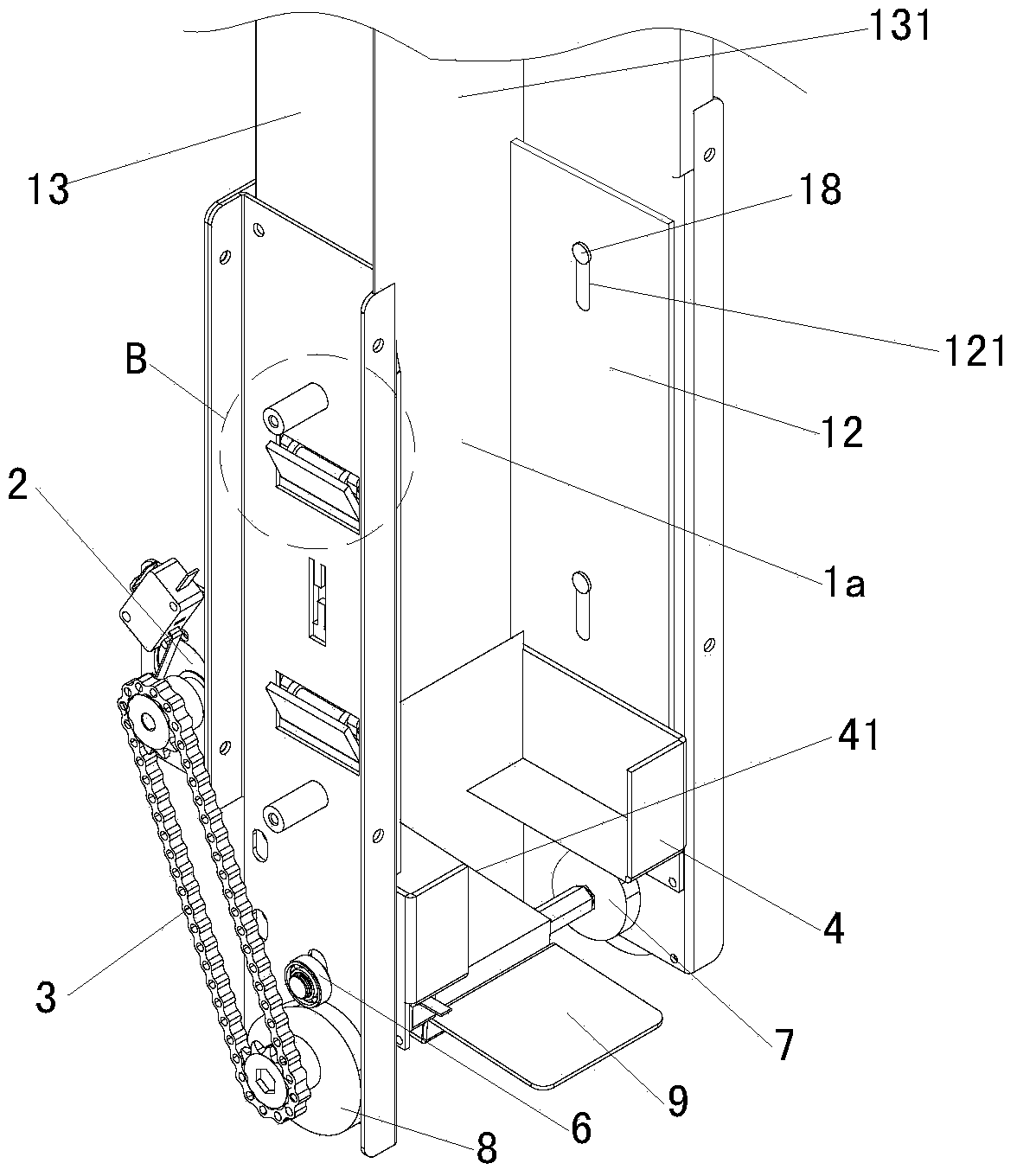

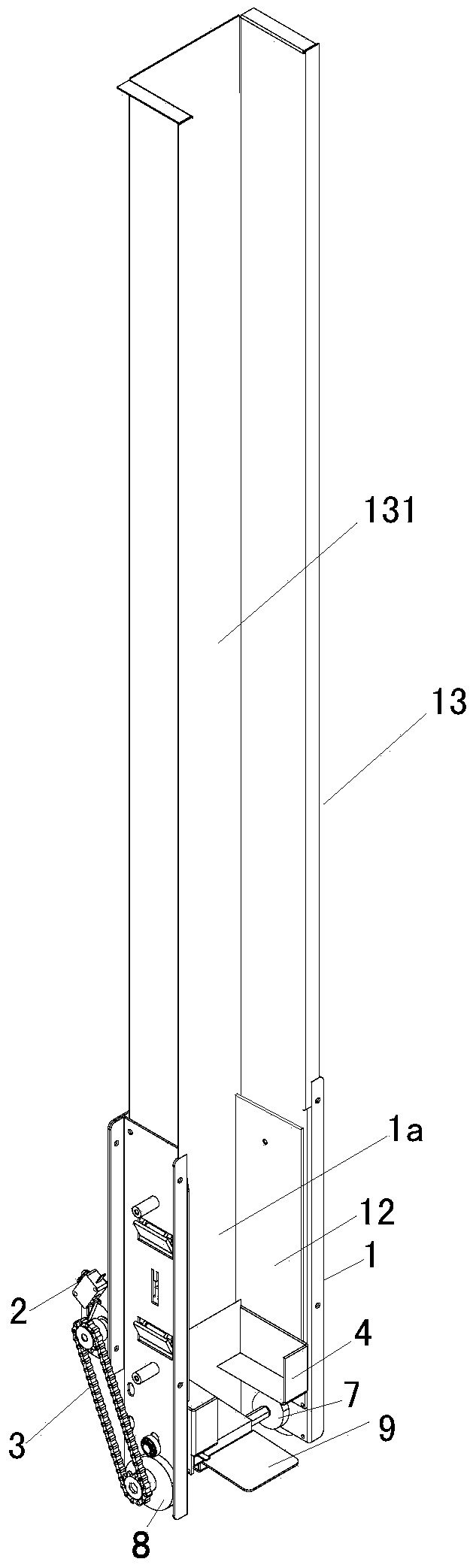

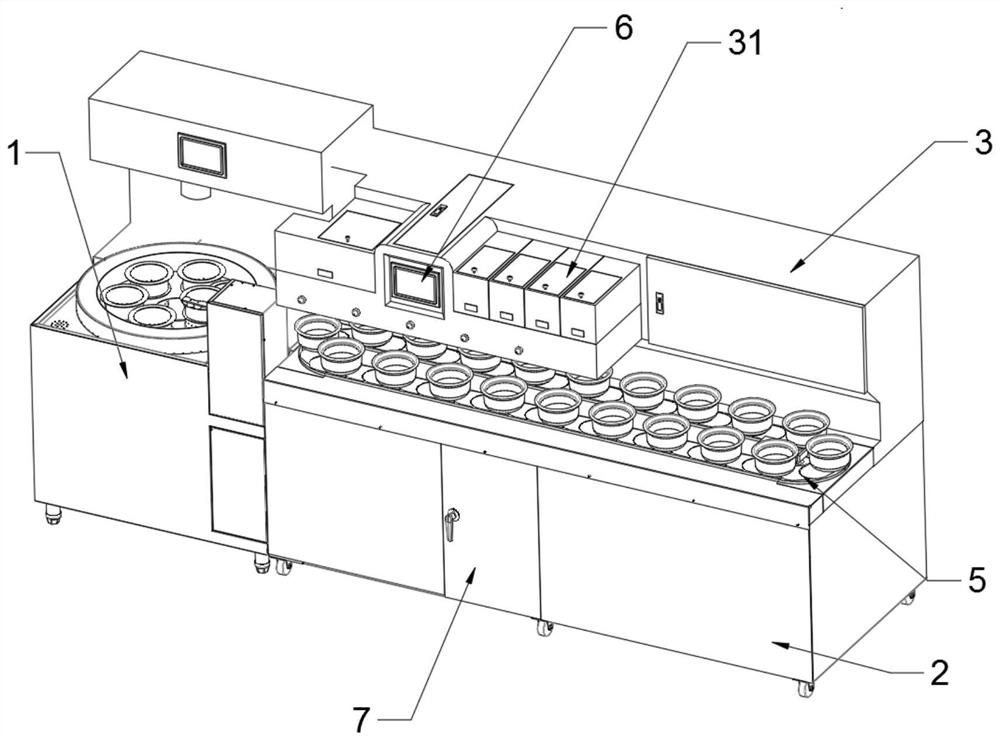

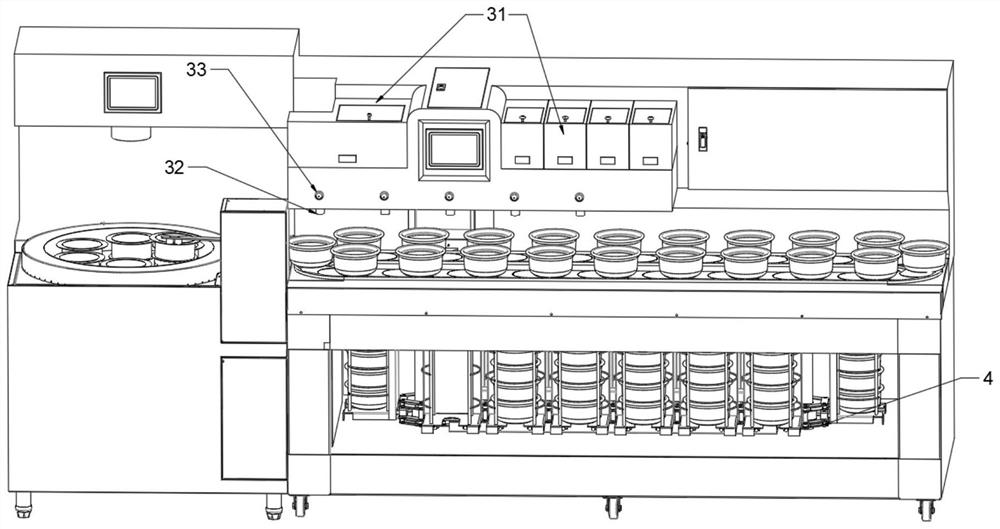

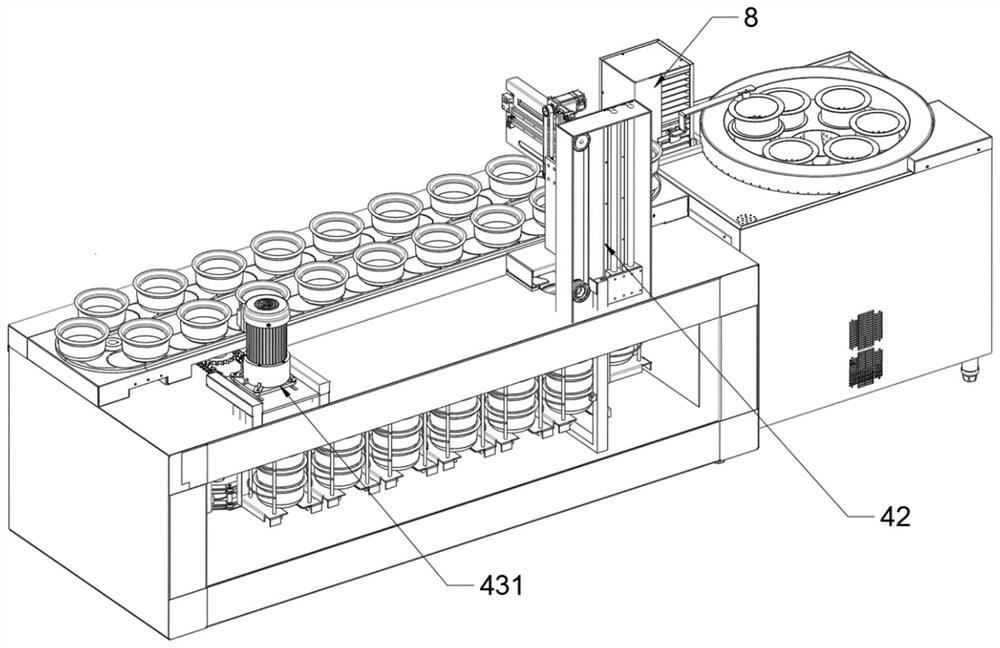

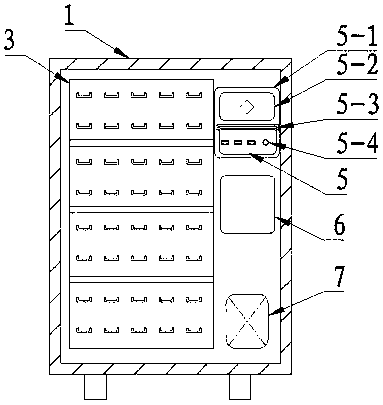

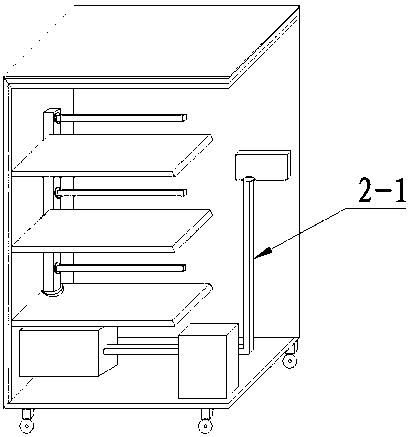

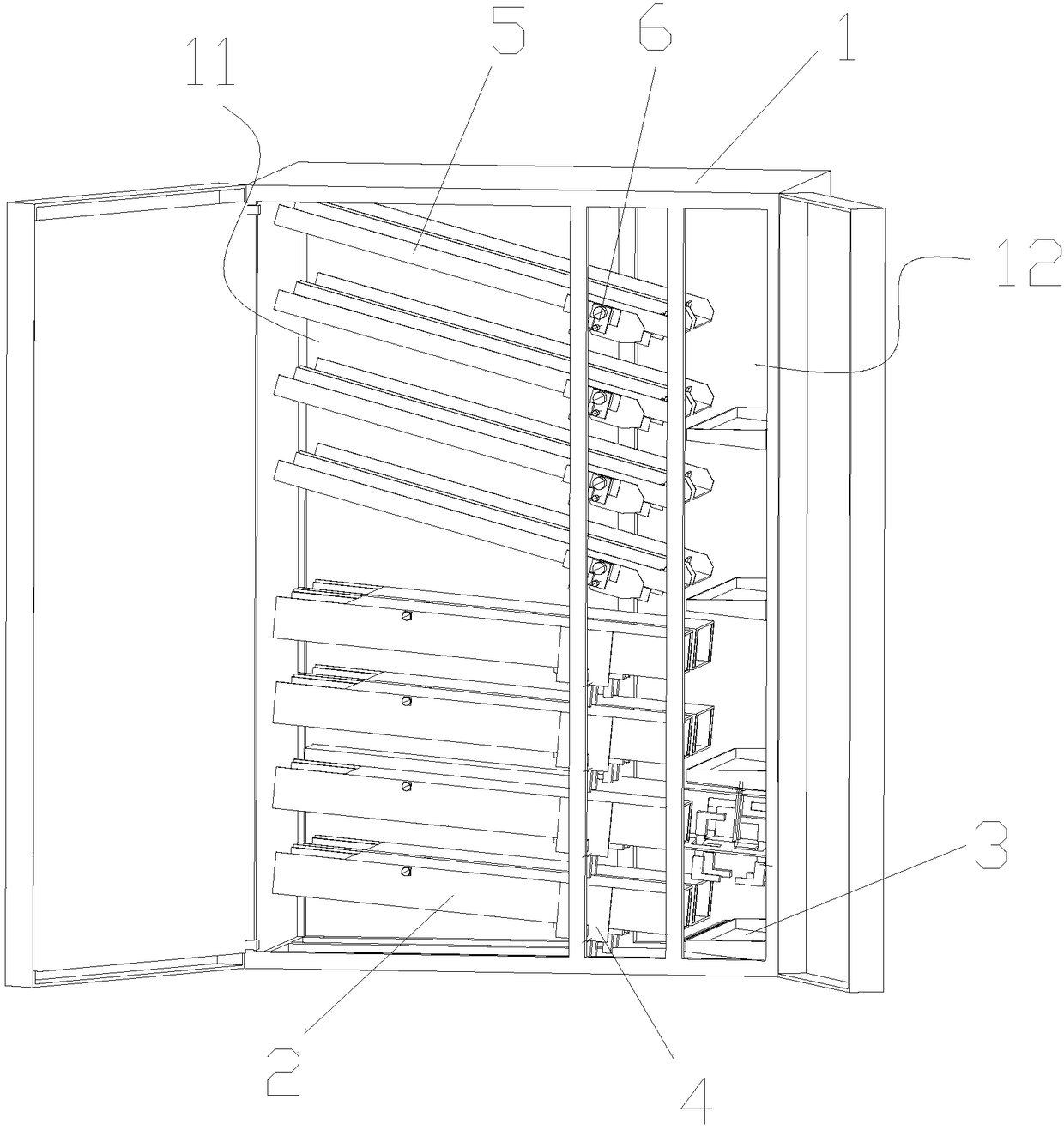

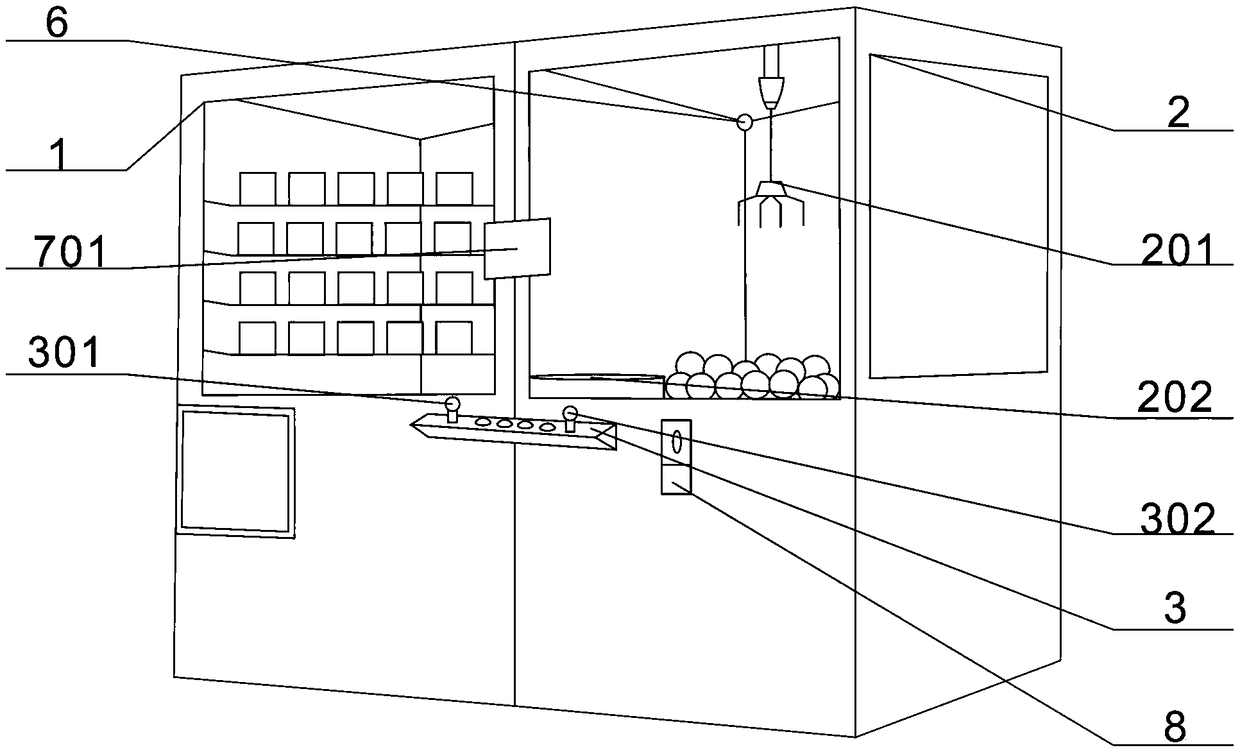

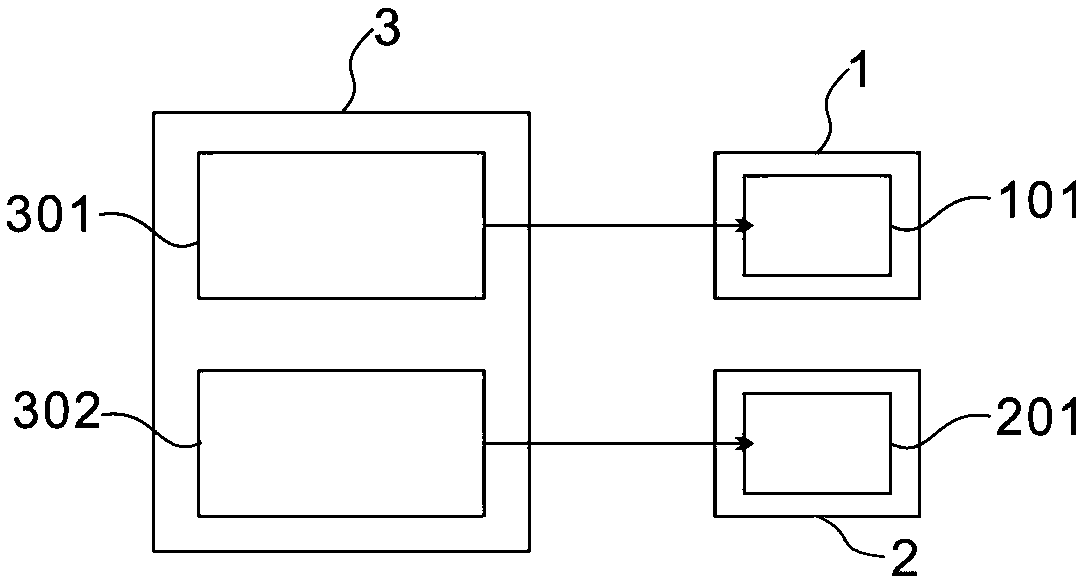

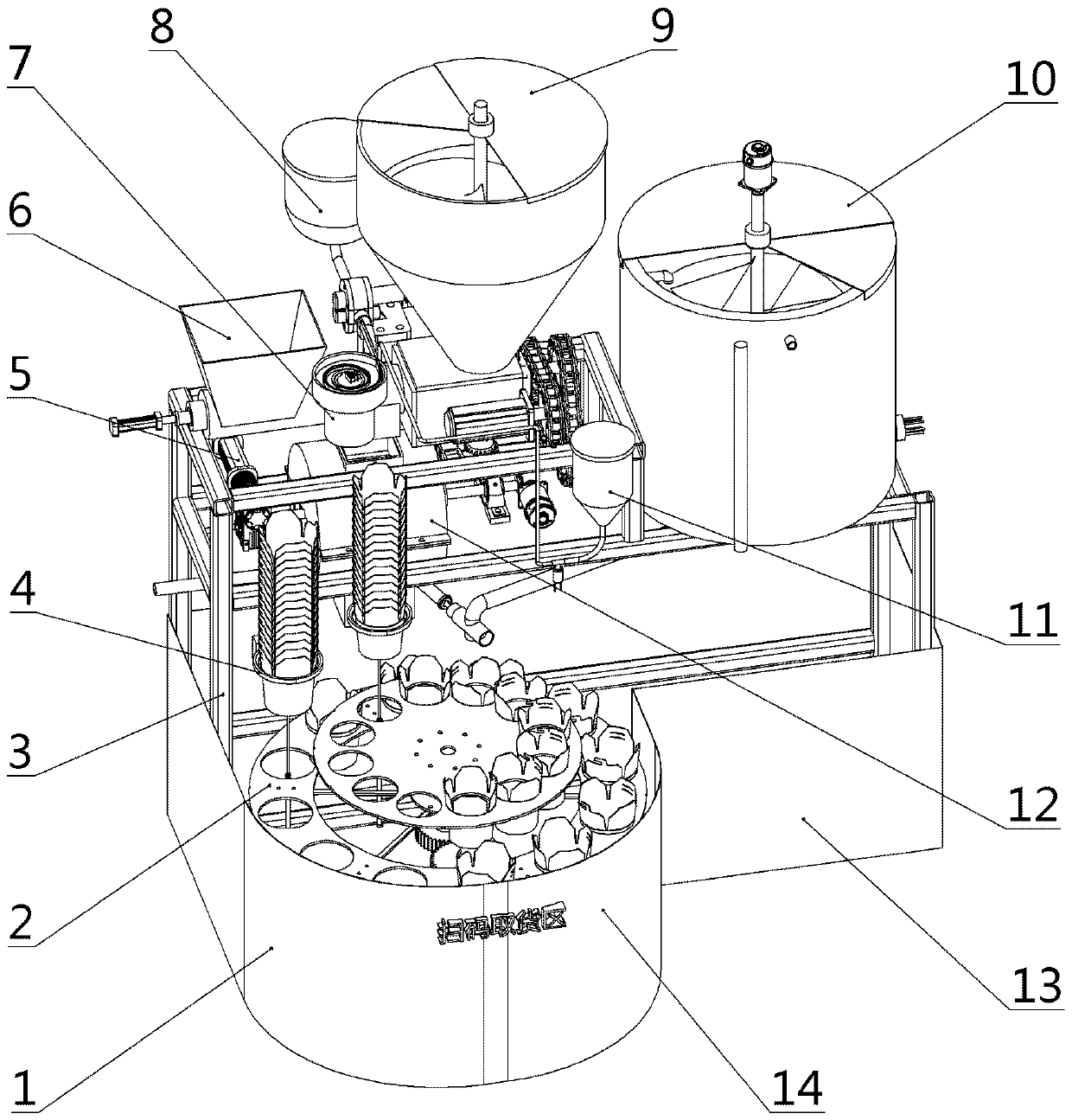

Automatic freshly-made wheaten food vending machine and working method thereof

ActiveCN107393176AReasonable structure layoutHigh degree of integrationApparatus for meter-controlled dispensingFood vending machinesAdditive ingredient

The invention discloses an automatic freshly-made wheaten food vending machine and a working method thereof, and relates to the technical field of automatic vending machines. The machine comprises a machine body, vending devices and a taking port are arranged on the exterior of the machine body, and the interior of the machine body comprises a mechanical arm, wheaten food cooking devices, sauce adding devices, conveying devices and an upper layer goods shelf which are arranged on an operation platform; wheaten food is obtained from the upper layer goods shelf by the mechanical arm, cooking of the wheaten food is completed by matching of the mechanical arm and the wheaten food cooking devices, saucer addition is conducted by the sauce adding devices, the wheaten food is seal-capped by a combined clamp and clamped to the conveying devices, and the finished products are conveyed to the taking port by the conveying devices. According to the automatic freshly-made wheaten food vending machine, structural configuration is rational, the integration degree is high, the working efficiency is high, fully automatic wheaten food product making and vending can be achieved, the freshness of the food is guaranteed, and health and sanitation are provided; meanwhile, the machine has various choices of flavors, food amounts and different ingredients, so that the requirements of customers are met.

Owner:罗志豪

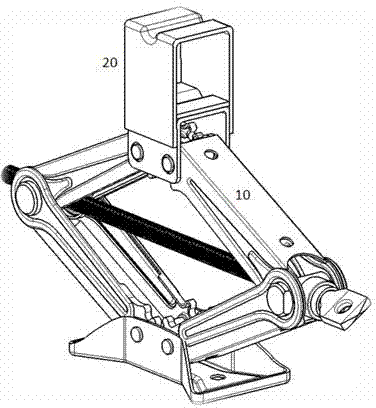

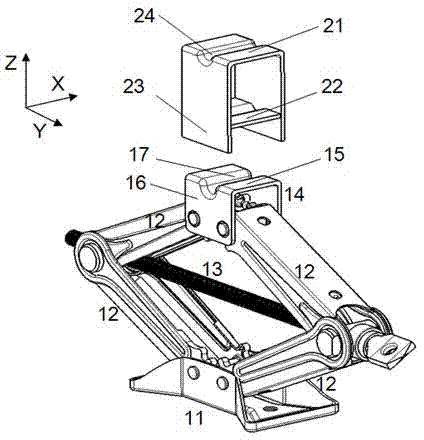

Automobile jack and lifting method thereof

ActiveCN103693580AHigh degree of generalizationMeet the lifting height requirementsLifting devicesAutomotive engineering

Owner:CHERY AUTOMOBILE CO LTD

Method for frozen-storage of persimmon when retail

InactiveCN1537454AExtended shelf lifeExpand the sales marketFood preservationFood preparationChemistryPreservation methods

A freeze storage method for persimmon when retail includes such steps as preparing raw materials, removing puckery taste, packing, quick freezing at -25 deg.C, and storing at -10- -20 deg.C for a long time. It can be directly eaten.

Owner:许穷腊

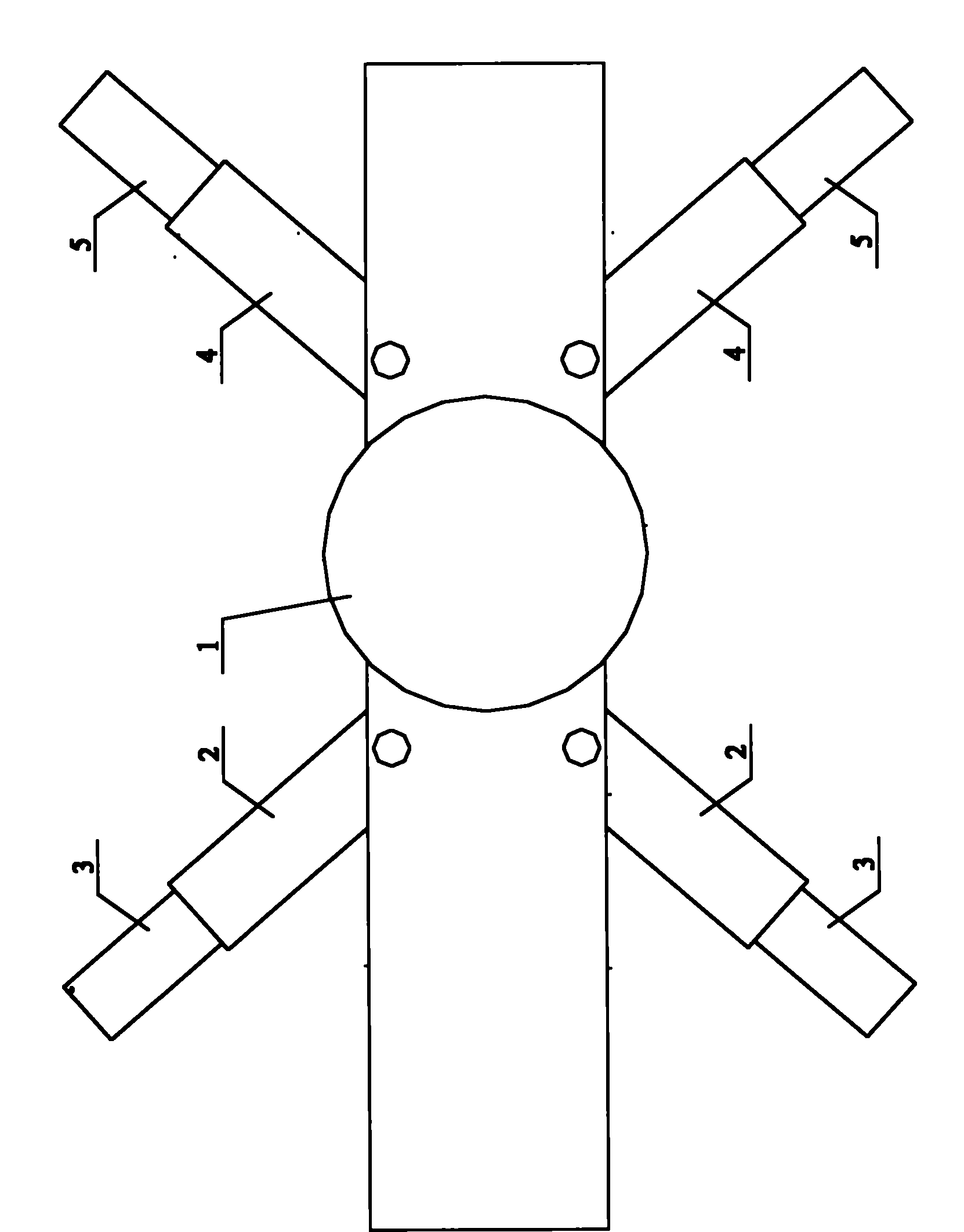

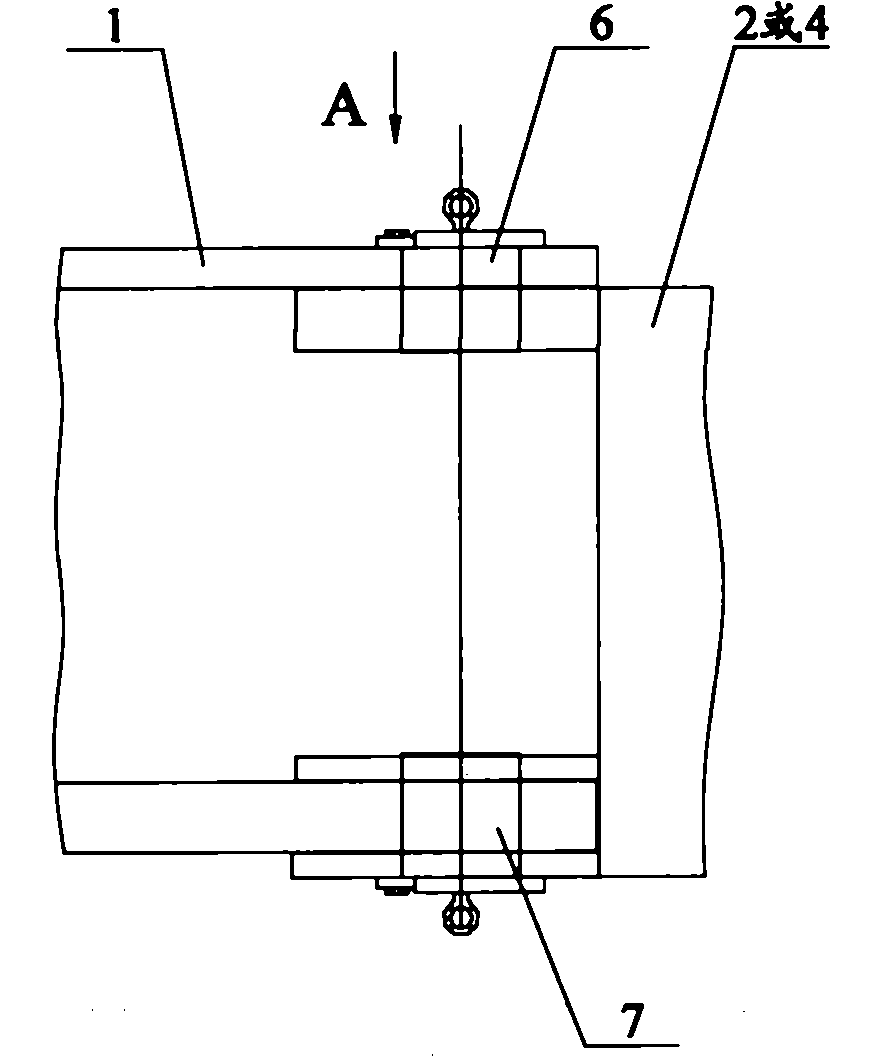

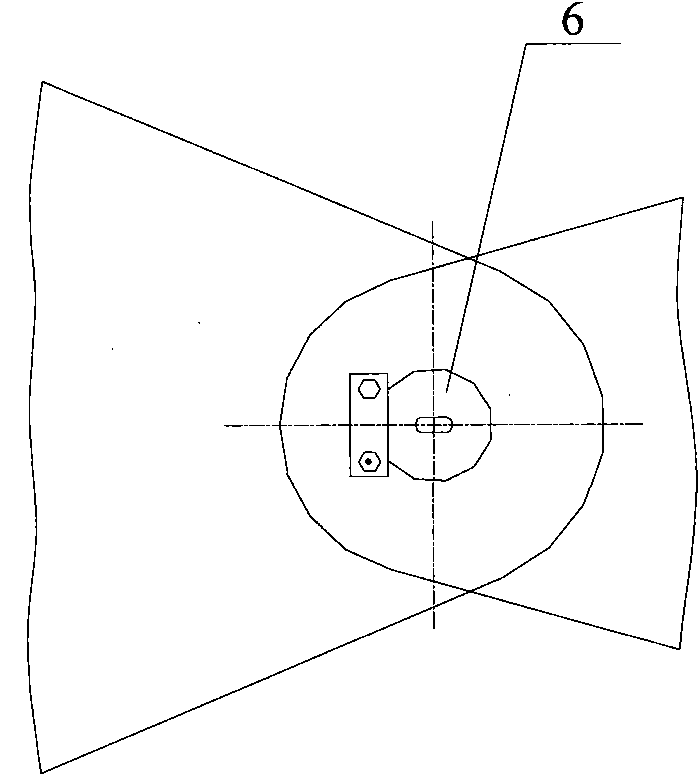

Wheel type engineering machinery and device for dismounting and mounting outrigger hinge pins thereof

The invention discloses a device for dismounting and mounting outrigger hinge pins of wheel type engineering machinery. The outrigger hinge pins are used for realizing the hinging between outriggers and a vehicle frame. The device comprises oil cylinders corresponding to the outrigger hinge pins and a hydraulic control loop, wherein a cylinder rod extending end of each oil cylinder is coaxially and fixedly connected with the corresponding outrigger hinge pin; and a control oil circuit of the hydraulic control loop is respectively communicated with cavities of the oil cylinders. Compared with the prior art, the device has the characteristics of simplicity for operation and labor saving and can be used for greatly increasing the working efficiency; and particularly for the operation of the hinge pin inserting, even through the centers of two structural members cannot be aligned correctly, the hinge pins can be inserted in reliably by means of hydraulic force. On the basis, the invention further provides the wheel type engineering machinery with the device for dismounting and mounting the outrigger hinge pins.

Owner:XUZHOU HEAVY MASCH CO LTD

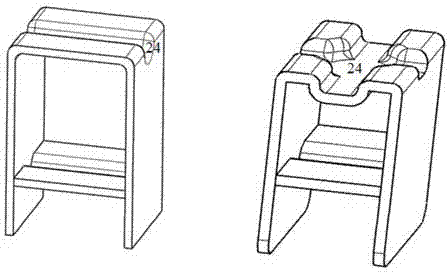

Box-packed commodity automatic delivery device

ActiveCN103832761AAchieve salesIncrease the number ofStorage devicesBiochemical engineeringReciprocating motion

The invention relates to a box-packed commodity automatic delivery device which comprises a commodity storage warehouse, clamping plates, a commodity containing warehouse, a shifting plate, a driving mechanism, an outer cam, an inner cam and a rotating shaft. A vertical channel is formed in the commodity storage warehouse, two sets of oppositely-arranged clamping plates are arranged on the two sides of the lower portion inside the vertical channel, the commodity containing warehouse is arranged below the clamping plates on the two sides of the bottom of the vertical channel, and is fixedly connected with the side wall of the commodity storage warehouse, a shifting plate moving opening is longitudinally formed in the commodity containing warehouse, the shifting plate is arranged below the commodity containing warehouse, on end of the shifting plate is fixedly connected with the middle of the rotating shaft, the other end of the shifting plate can do reciprocating motion in the shifting plate moving opening, and the driving mechanism which drives the rotating shaft to rotate is arranged at one end of the rotating shaft.

Owner:HANGZHOU JIEKONG TECH

Method for treating titaniferous blast furnace slag

The invention discloses a method for treating titaniferous blast furnace slag to recycle titanium, silicon, aluminum, calcium and magnesium. The titaniferous blast furnace slag is especially titaniferous blast furnace slag obtained by carrying out iron making on vanadium titanomagnetite in Panzhihua regions. The method comprises the following steps: carrying out acid leaching (especially multistage acid leaching) on furnace slag to obtain an acid leaching solution and white carbon black; and carrying out an extraction technique on the acid leaching solution to obtain titanium, aluminum, calcium, magnesium, manganese, iron, chromium, vanadium and other useful metals. On the premise of recycling resources, the method implements cyclic utilization of waste (using waste of one technique as a raw material of another technique), eliminates waste discharge, obviously lowers the cost and enhances the recycling efficiency.

Owner:衡阳市金铭环境科技有限公司

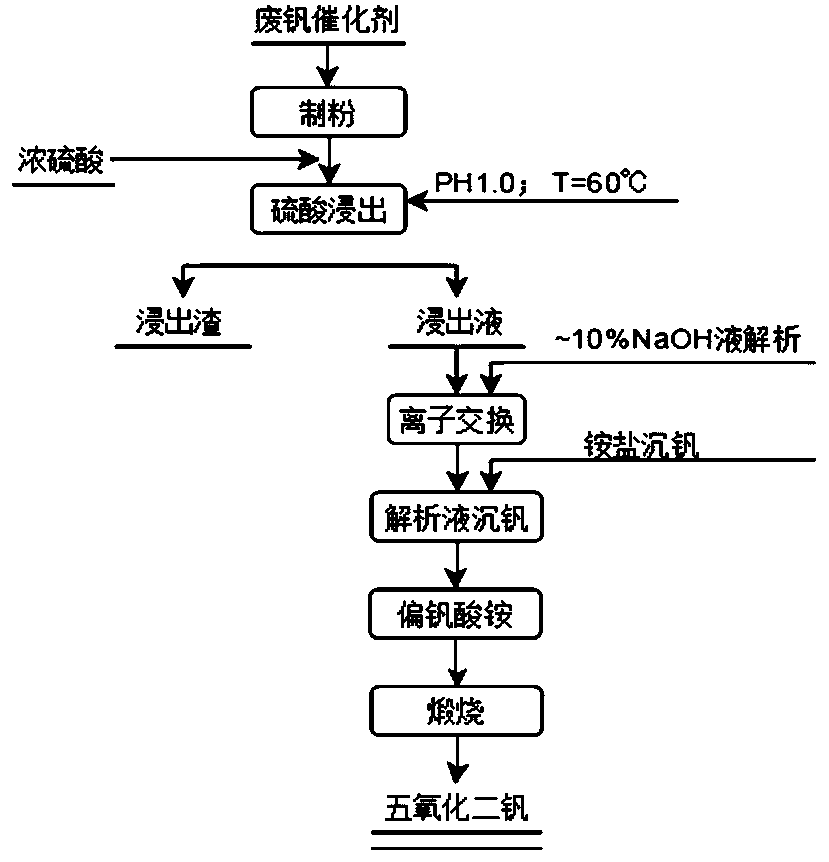

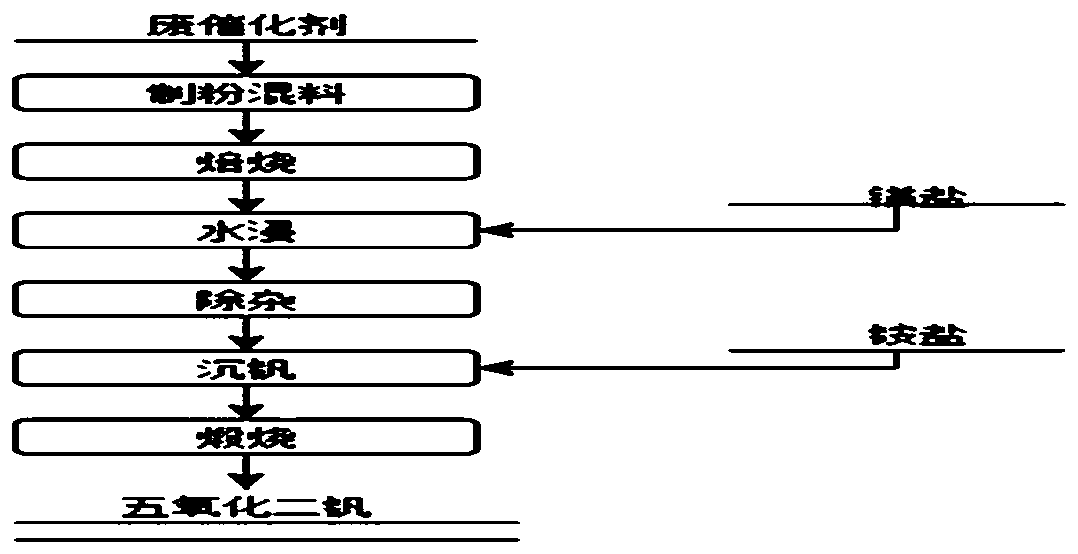

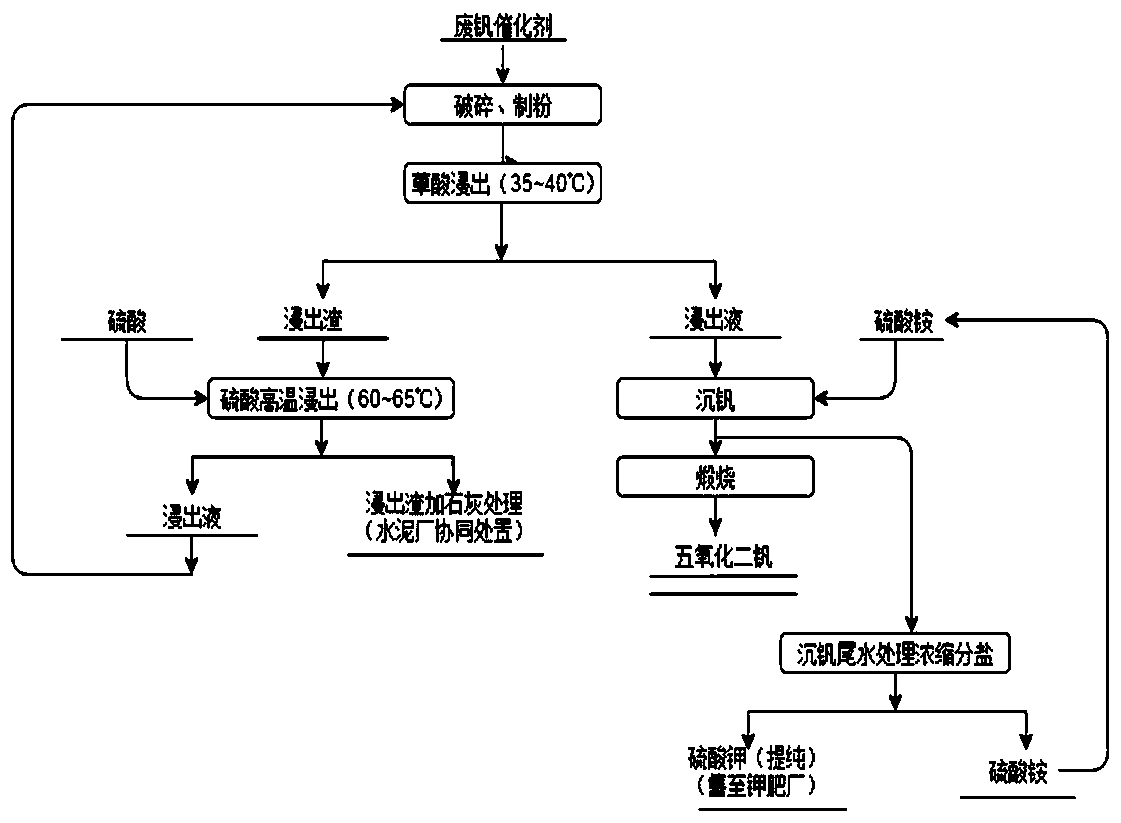

Method for preparing vanadium pentoxide by treating vanadium-containing waste sulfuric acid catalyst through two-step method

ActiveCN111455186AControl leaching rateReduce processing difficultyProcess efficiency improvementOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a method for preparing vanadium pentoxide by treating a vanadium-containing waste sulfuric acid catalyst through a two-step method. The pH value is controlled to be 5-6 throughoxalic acid leaching in a first step, namely the leaching rate of vanadium is controlled to be between 65% and 75%, and simultaneously a large amount of impurities (Al, Ni, Cu and the like) are inhibited from being separated out; the PH is controlled to be 1.5-2.0 through sulfuric acid leaching in a second step, the leaching accumulation of vanadium is controlled to be larger than or equal to 90%, meanwhile, a small amount of impurities such as Al are leached, leaching liquid returns to the first step of oxalic acid leaching (when the small amount of impurities leached in the second step return to the first step of leaching, precipitates are generated again and enter slag), and meanwhile, the first-step leaching is completed by utilizing the temperature of the leaching liquid, so that thecost is reduced; leaching residues are washed in the second step, the leaching residues are centrally collected, lime is added to be mixed, and the mixture is sold to a cement plant to serve as clinker of the cement plant; the leaching liquid is prepared after the first step of oxalic acid leaching, vanadium precipitation of ammonium sulfate is directly adopted to prepare an ammonium polyvanadateintermediate product, concentrated sulfuric acid needs to be added in the production process, residual oxalic acid in the leaching liquid completely reacts with the concentrated sulfuric acid to eliminate obstacles for subsequent water treatment, and solid ammonium sulfate prepared after water treatment returns to a production system, and potassium sulfate is purified and sold to potash fertilizer production enterprises to be used as a raw material.

Owner:江苏美东环境科技有限公司

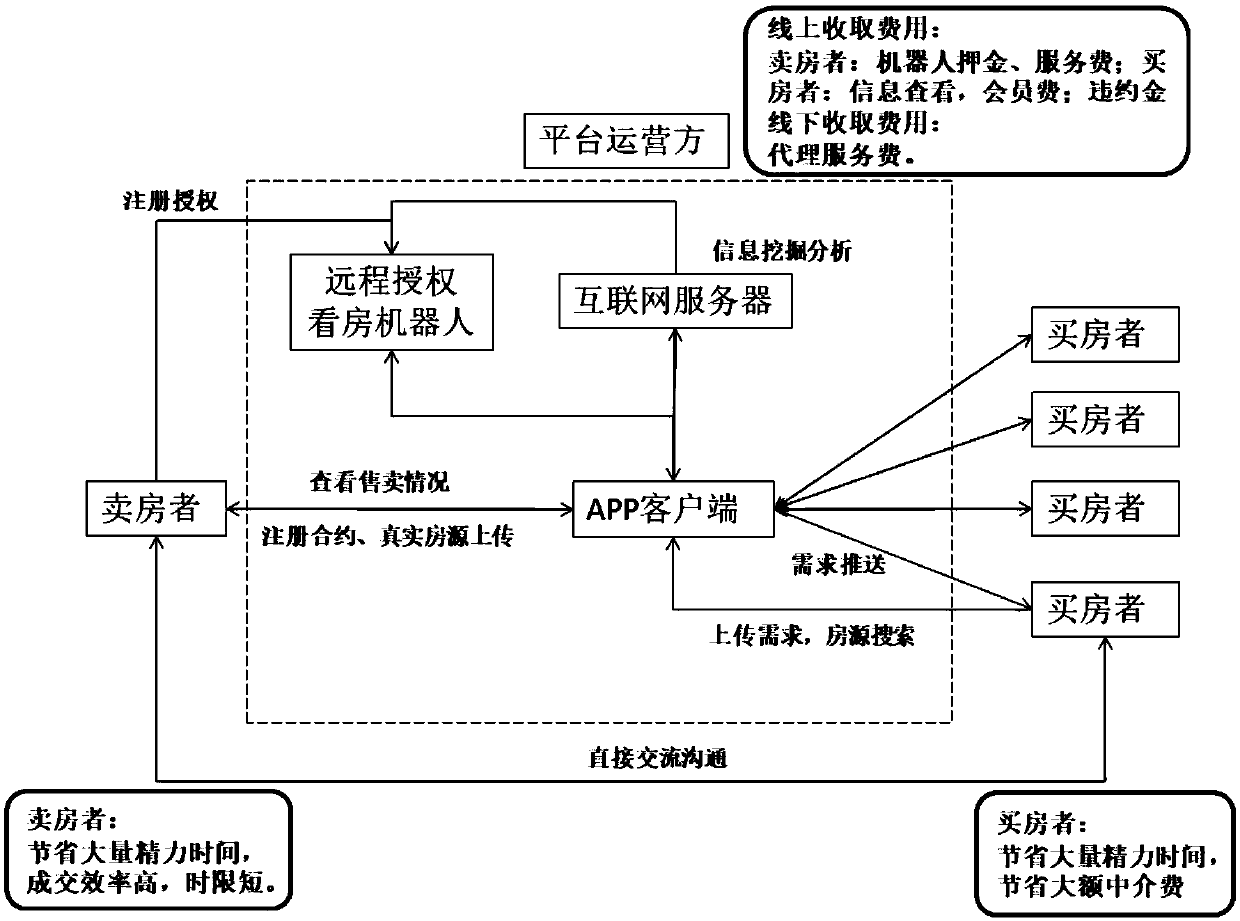

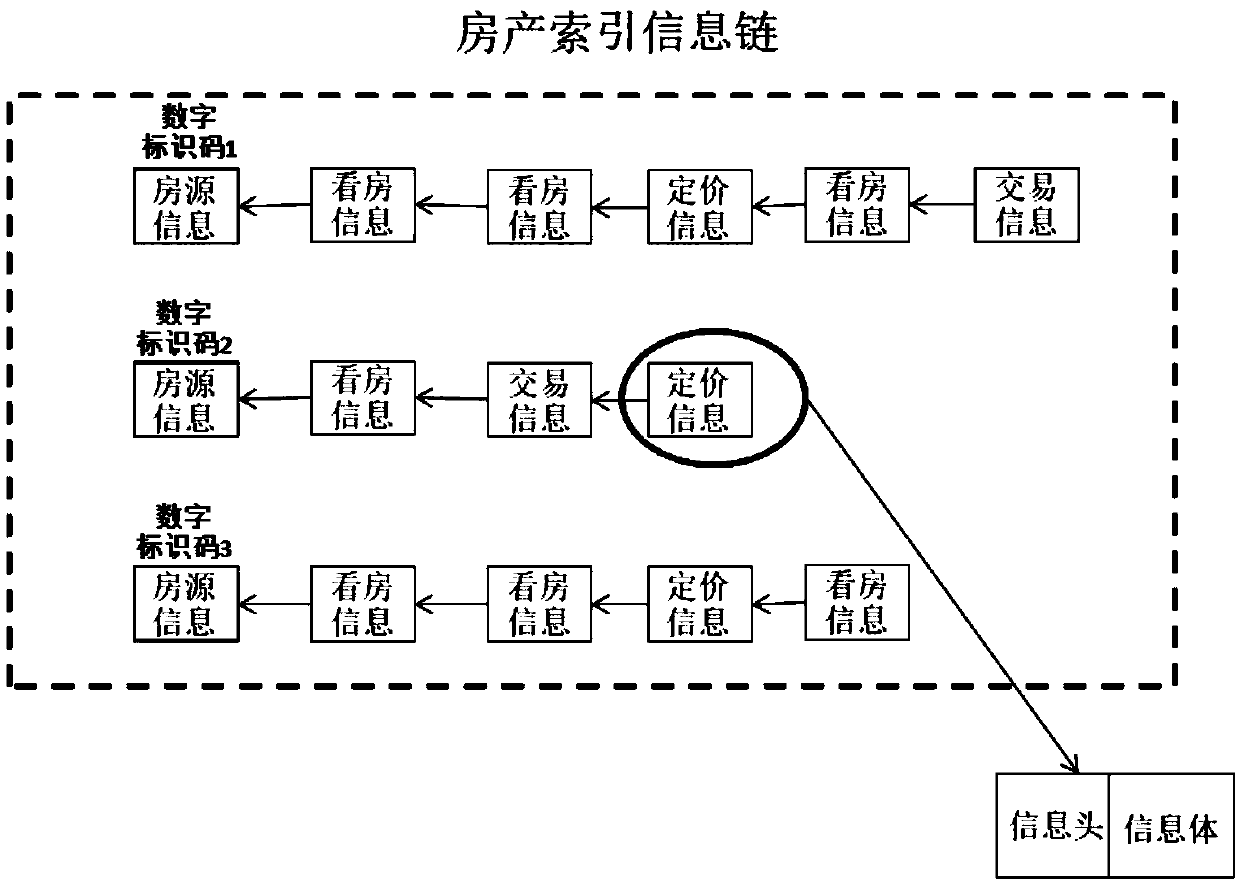

Second-hand housing transaction method

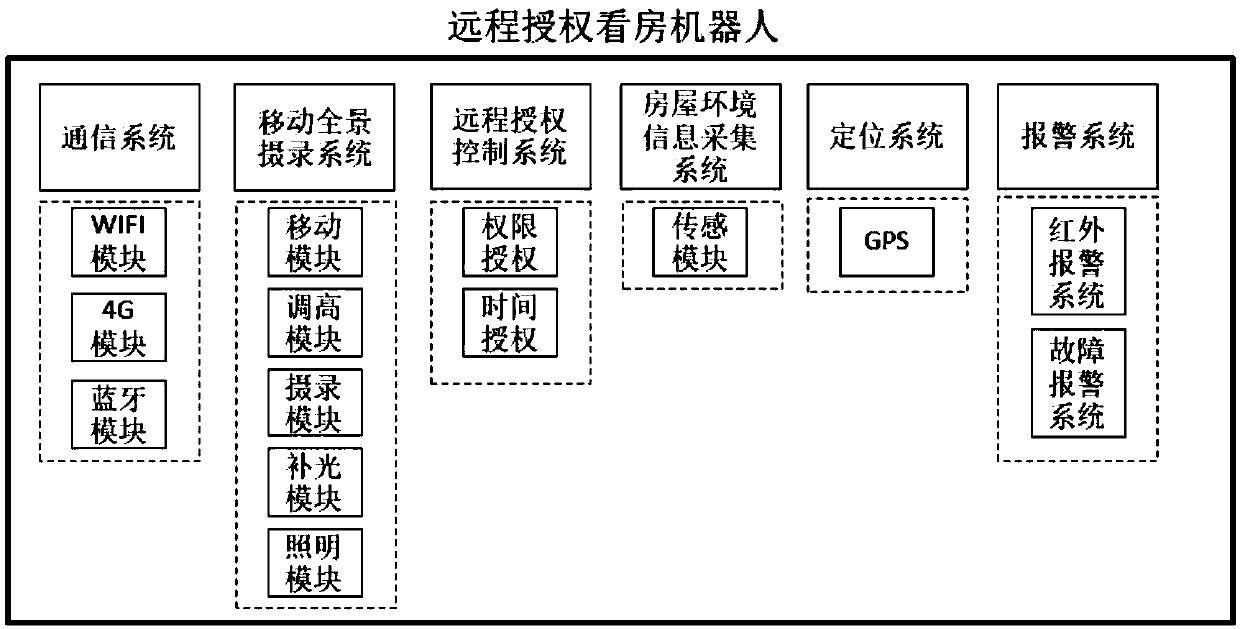

ActiveCN109636452ABreak harassmentRealize full traceabilityCustomer communicationsBuying/selling/leasing transactionsInformation resourceEnergy expenditure

A business mode of second-hand housing transaction is characterized in that organization bearing the business mode comprises a second-hand house direct transaction party and a platform operator, the second-hand housing direct transaction party comprises a house buyer and a house seller, and the platform operator is a provider of an internet server, a remote authorization house inspection robot andan APP client. According to the business mode, the harassment of false house source information and non-real house buyers to the house sellers is broken, and the reality and reliability of the housebuyers and the house sources are ensured; information resources and time are packaged and stored to realize information traceability in the whole process; through the remote authorization of the houseinspection robot, the cost and energy expenditure are saved in space and time, and a premise is provided for rapid and efficient house transaction. The business mode runs, so that the house propertytransaction process is efficiently and quickly carried out, the second-hand house is sold in a non-intermediary mode, and win-win of a house seller, a buyer and a platform operator is realized.

Owner:郭云峰

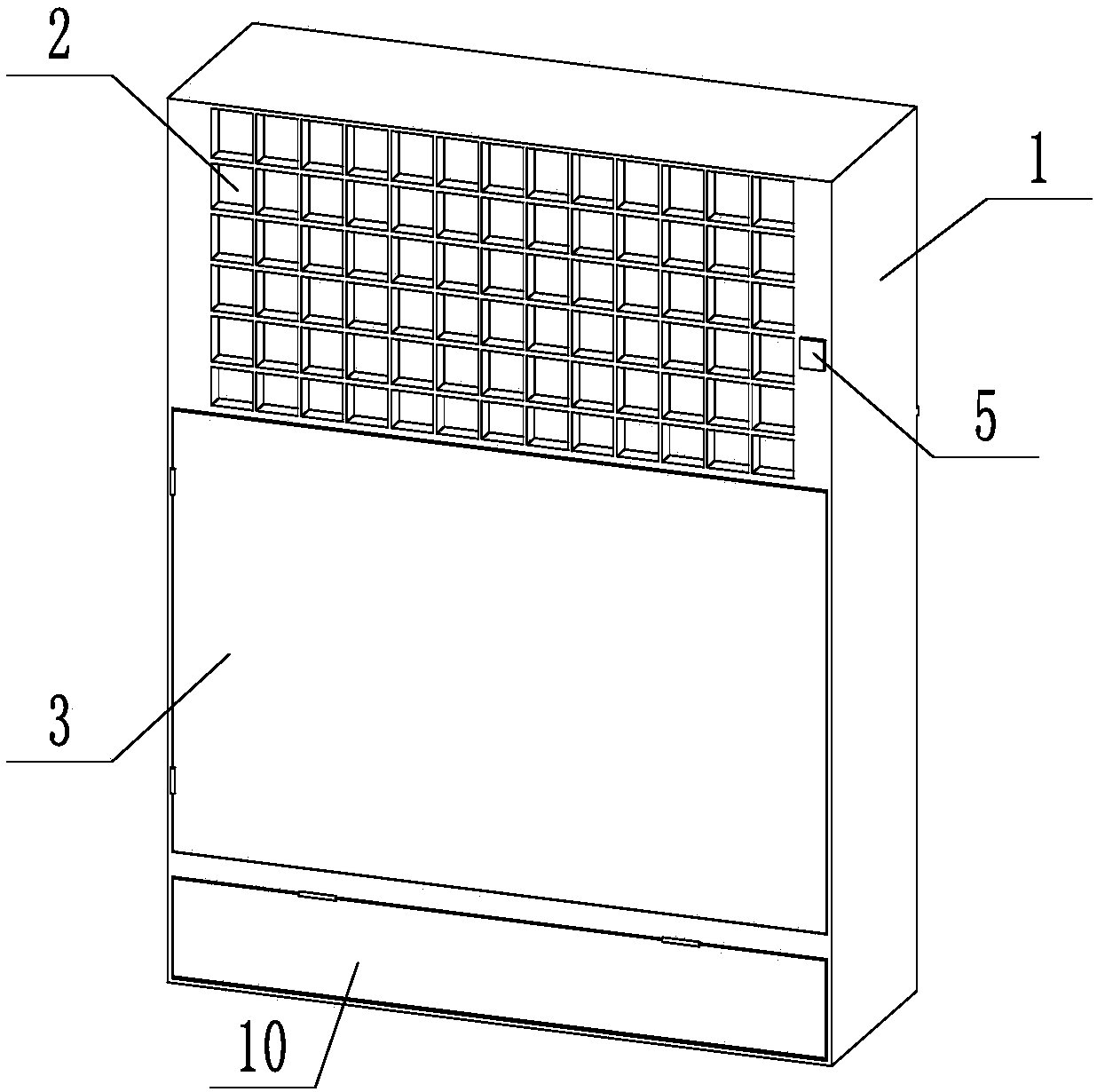

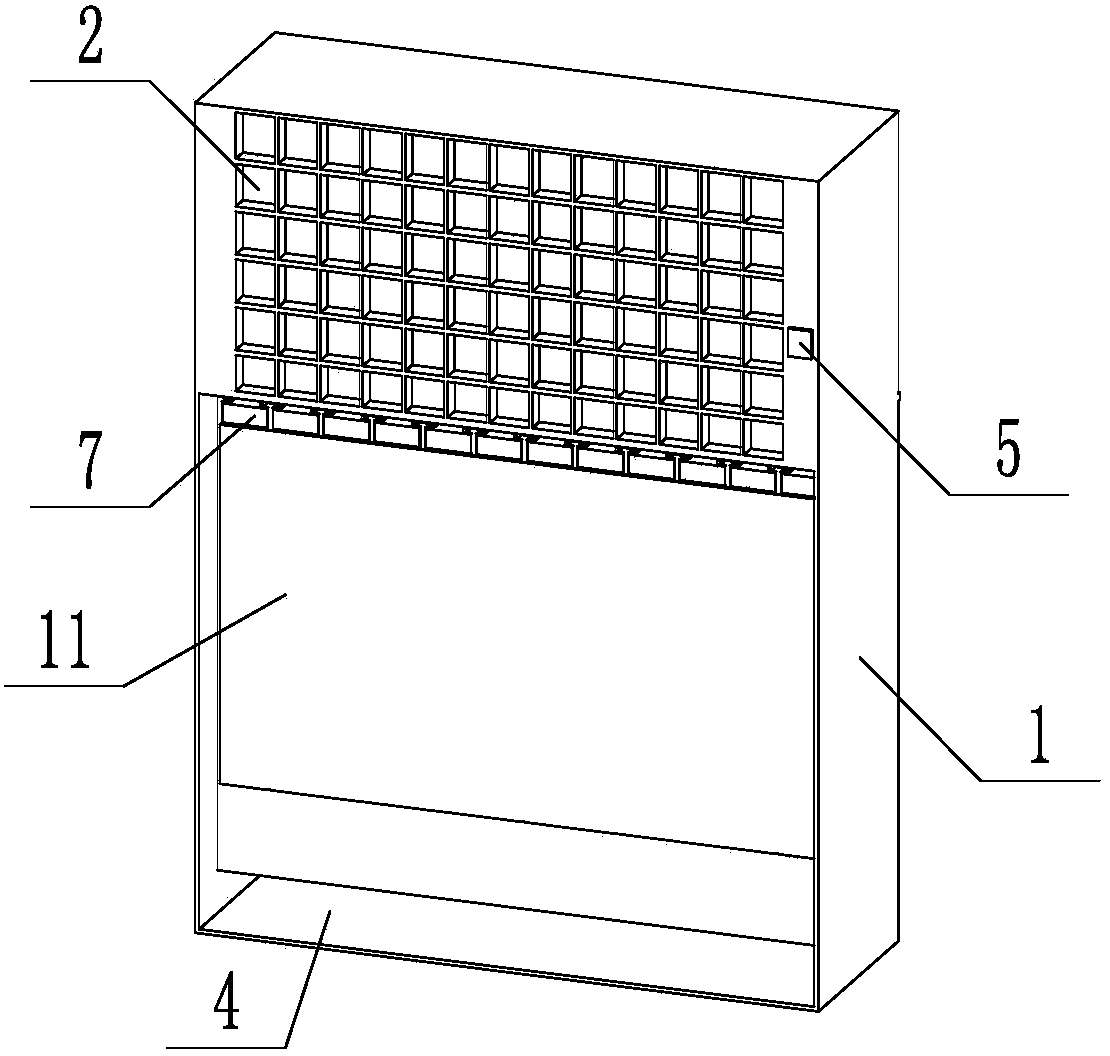

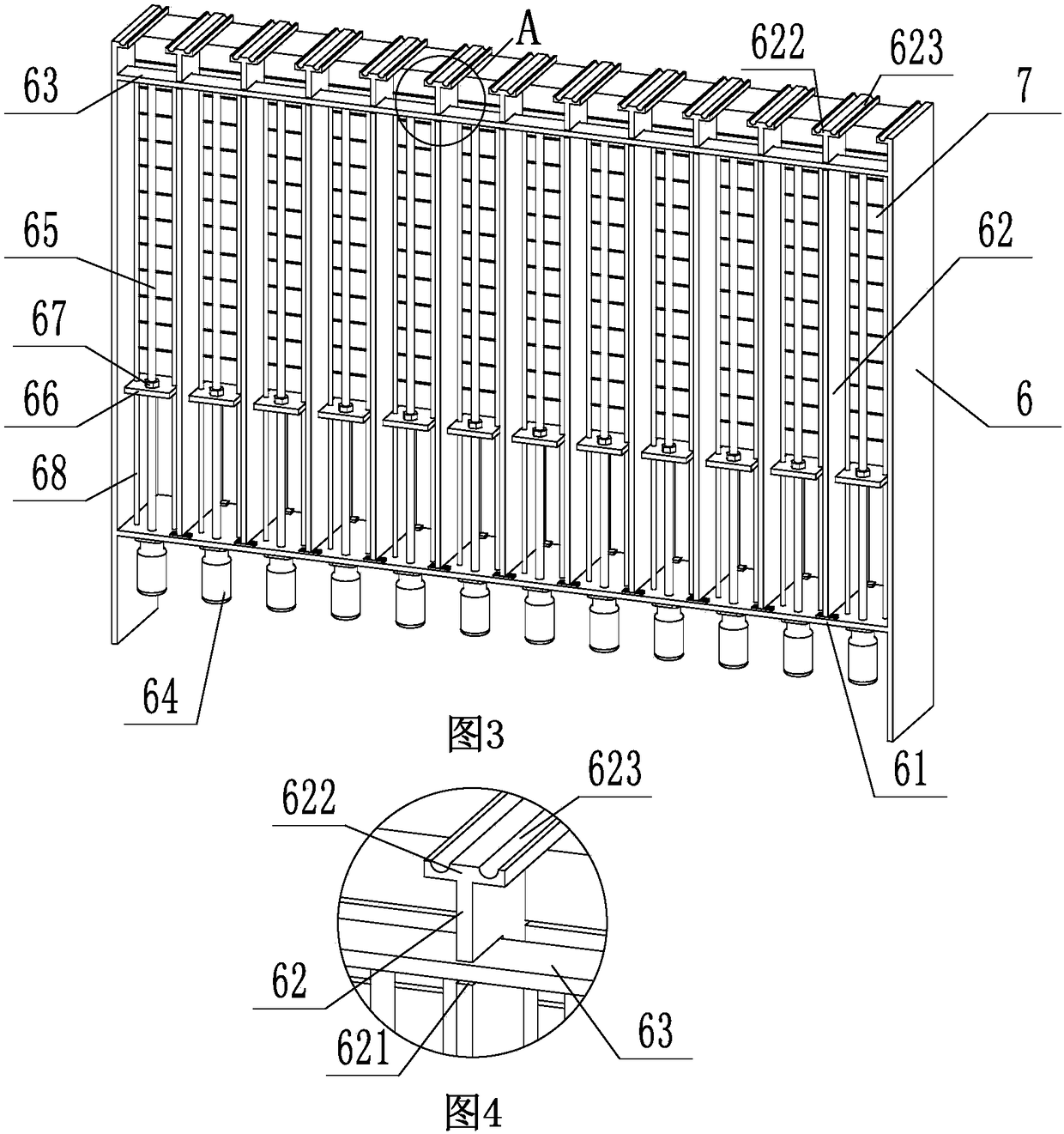

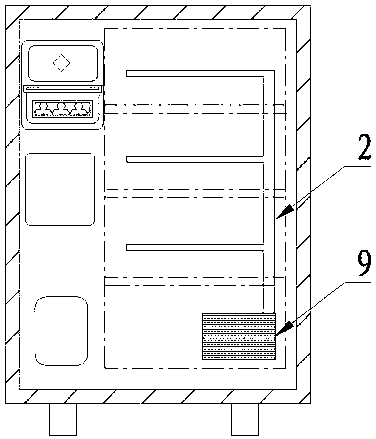

Smart cigarette selling shelf based on Internet of things, selling method and counting method

InactiveCN108597105AAchieve salesEasy to operateShow cabinetsCoin-freed apparatus detailsHydraulic cylinderDrive motor

The invention discloses a smart cigarette selling shelf based on Internet of things, a selling method and a counting method. The smart cigarette selling shelf comprises a shell, wherein a display cabinet, a storage cabinet and a delivery cabinet are arranged in the shell from top to bottom in sequence; a delivery door is arranged at the front end of the delivery cabinet; the front side face of theshell is provided with a two-dimensional code; a storage shelf is arranged in the storage cabinet; the storage shelf comprises a first transverse plate and vertical plates which are arranged at the bottom end; a cigarette box is positioned between two adjacent vertical plates; a driving motor is arranged at the lower end of the first transverse plate; the output end of the driving motor is connected with a threaded rod; the threaded rod rotates in the storage shelf; the threaded rod is provided with a top plate; the top plate is provided with a nut; the threaded rod is in threaded connectionwith the nut; a hydraulic cylinder is arranged at the back end of the shell; a pushing frame is arranged at the output end of the hydraulic cylinder; the pushing frame slides at the upper ends of thevertical plates; the driving motor rotates to drive the threaded rod to rotate; the cigarette box moves upwards along with the top plate; when the cigarette box moves to the hydraulic cylinder, the hydraulic cylinder pushes the cigarette box off to take a cigarette out. The operation is easy and convenient, and the sale of cigarettes is realized.

Owner:SHANDONG YANTAI TOBACCO +1

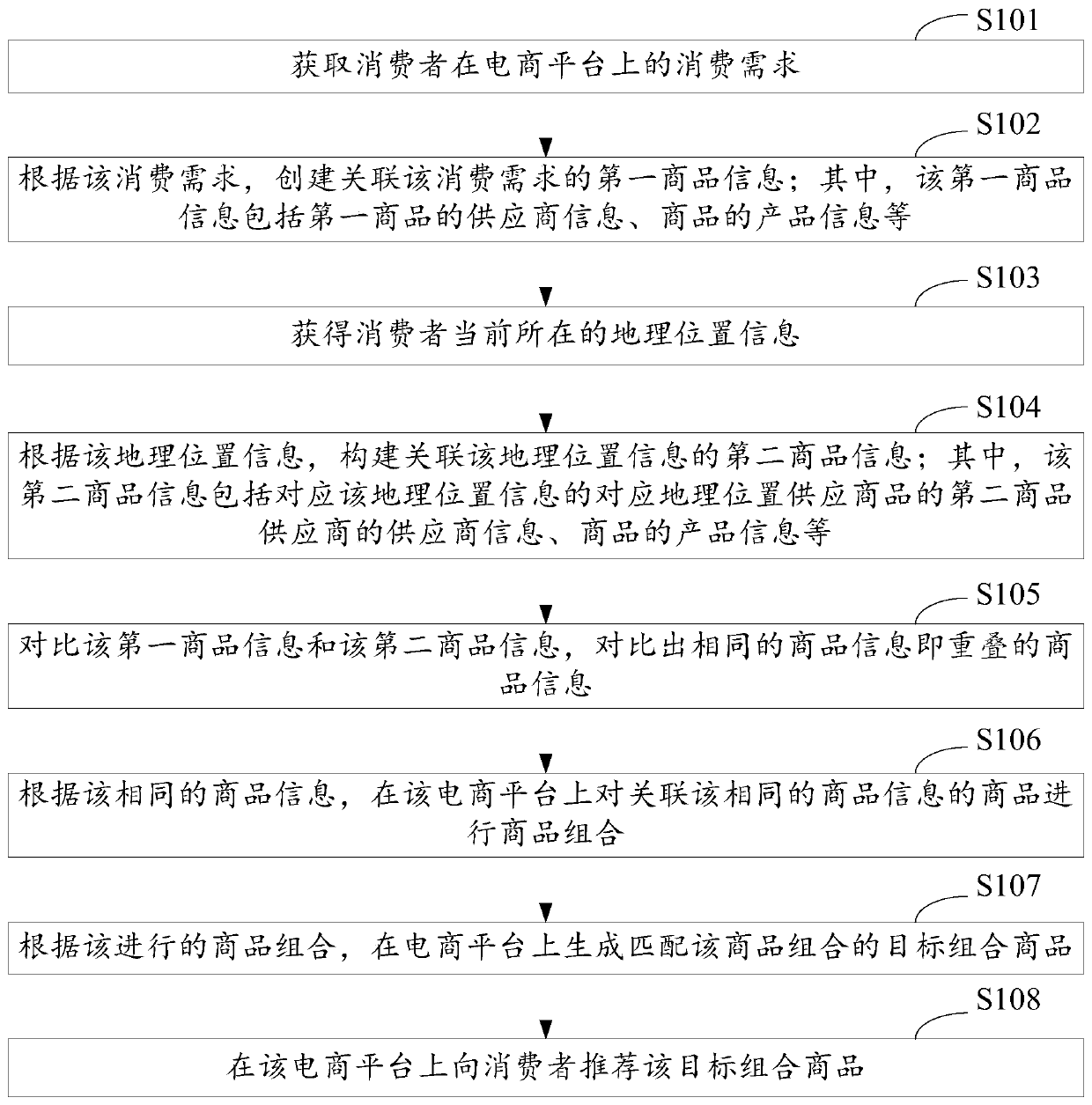

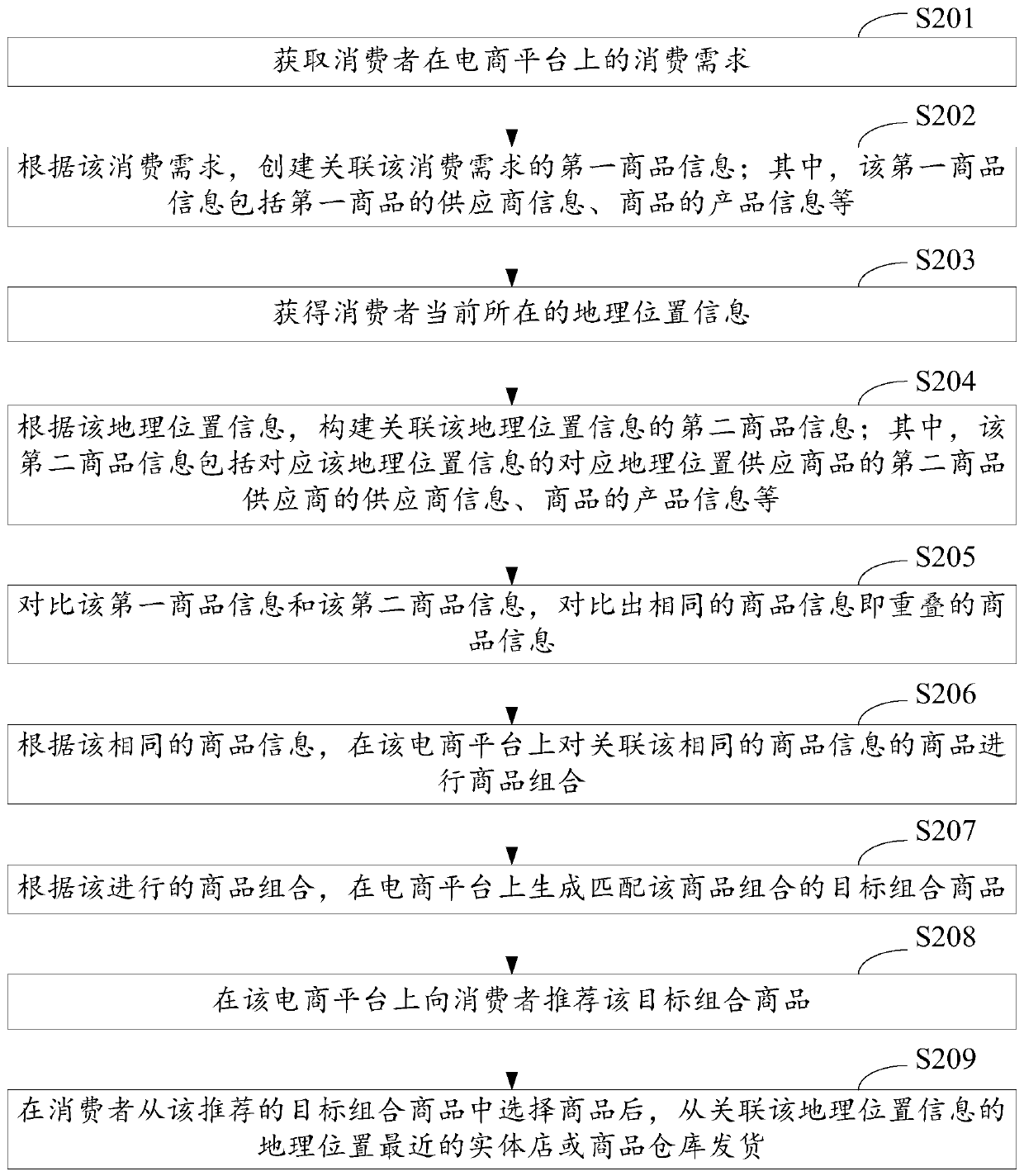

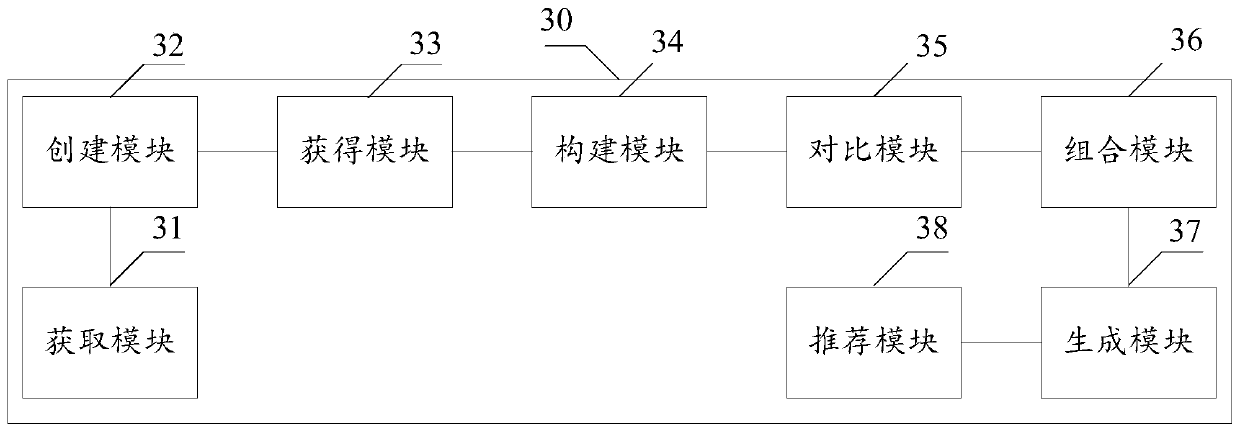

Commodity recommendation method, device and equipment based on e-commerce platform

InactiveCN111062787AObtain consumer demandIncrease salesMarket predictionsDigital data information retrievalConsumer demandDatabase

The invention discloses a commodity recommendation method, device and equipment based on an e-commerce platform. The method comprises the following steps of obtaining a consumption demand of a consumer on the e-commerce platform; depending on the consumer demand, creating first commodity information associated with the consumption demand, obtaining current geographical location information of theconsumer; constructing second commodity information associated with the geographic position information, comparing the first commodity information with the second commodity information to obtain the same commodity information through comparison, carrying out commodity combination on commodities associated with the same commodity information on the e-commerce platform according to the same commodity information, generating a target combined commodity matched with the commodity combination on the e-commerce platform, and recommending the target combined commodity to consumers on the e-commerce platform. By means of the mode, the commodities can be recommended for sale according to the consumption requirements of consumers on the e-commerce platform and the current geographic position information, and then the sales volume of the recommended commodities on the e-commerce platform can be increased.

Owner:广东奥园奥买家电子商务有限公司

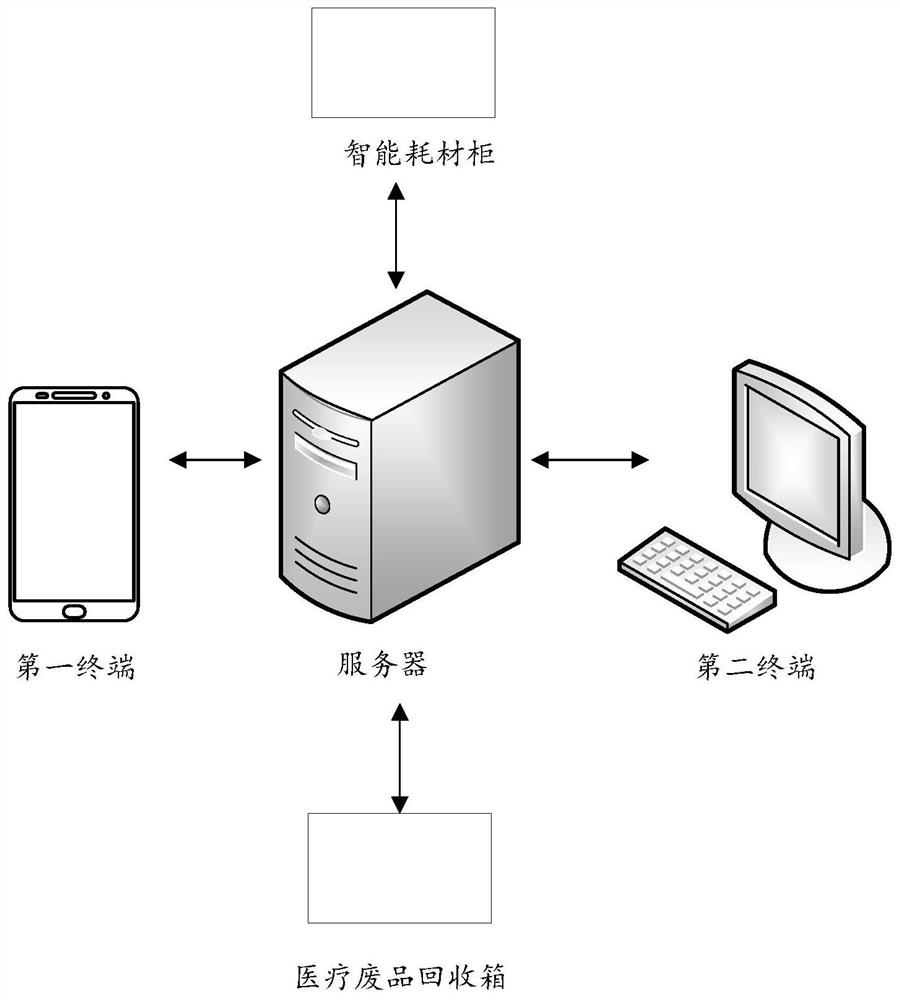

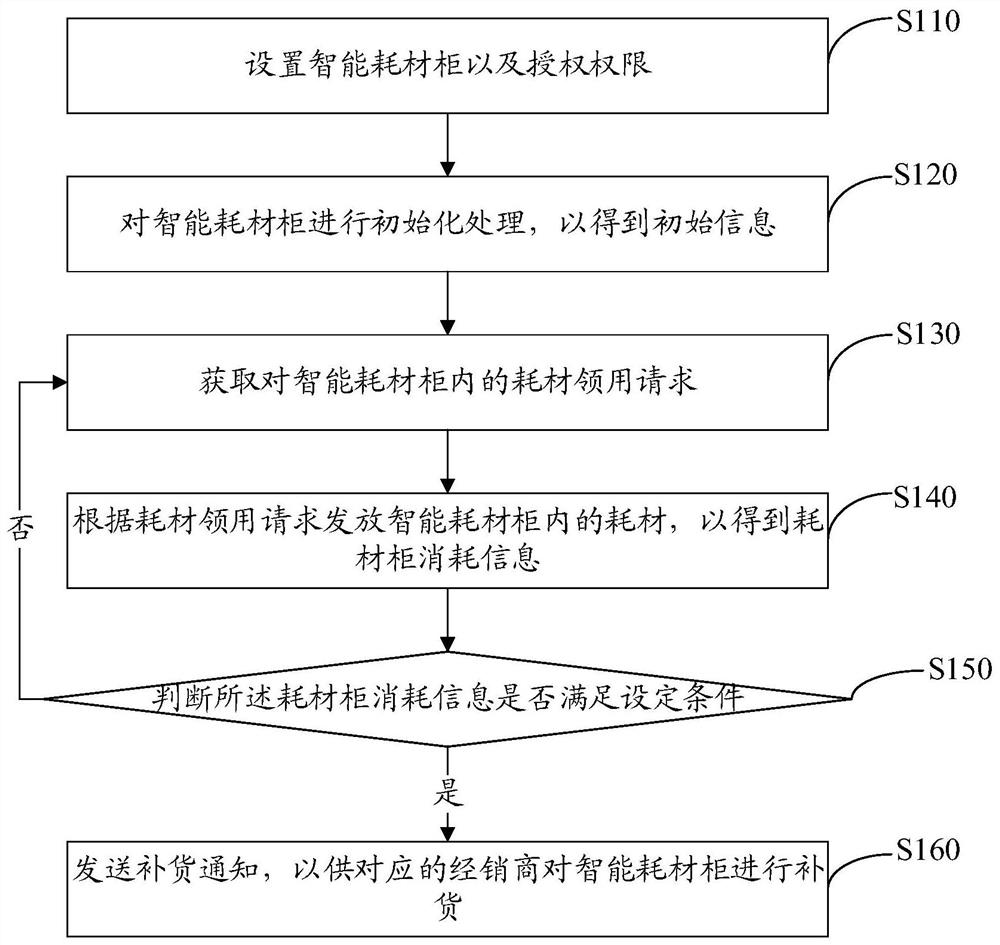

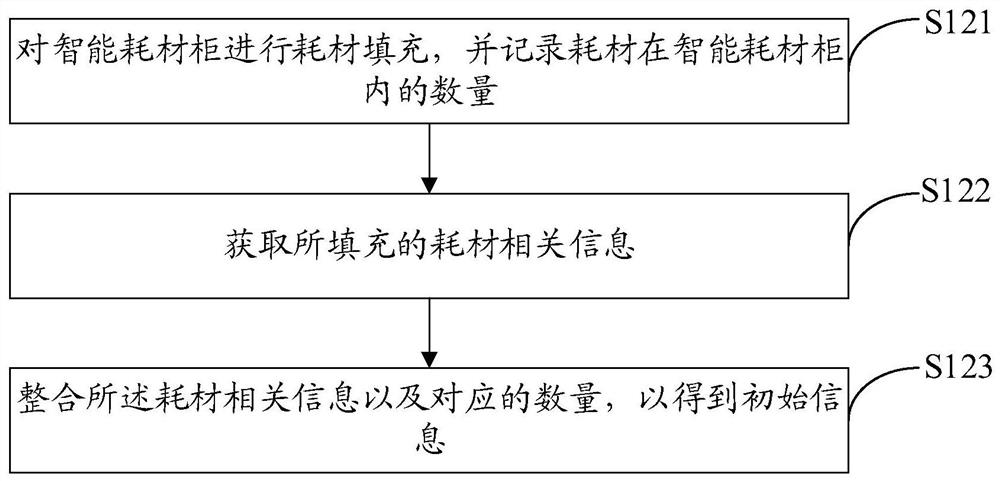

Medical consumable sales management method and device, computer equipment and storage medium

PendingCN112530556ATimely replenishmentAchieve salesBuying/selling/leasing transactionsHealthcare resources and facilitiesAuthorizationInformation acquisition

The invention relates to a medical consumable sales management method and device, computer equipment and a storage medium. The method comprises the following steps: setting an intelligent consumable cabinet and authorization authority; carrying out initialization processing on the intelligent consumable cabinet to obtain initial information; obtaining a consumable receiving request in the intelligent consumable cabinet; distributing consumables in the intelligent consumable cabinet according to the consumable receiving request to obtain consumable cabinet consumption information; judging whether the consumable cabinet consumption information meets a set condition or not; and if yes, sending a replenishment notice for a corresponding dealer to replenish the intelligent consumable cabinet. By arranging the intelligent consumable cabinet, a consumable receiving request, consumable replenishment and the like are directly executed by the intelligent consumable cabinet, after identity verification is conducted on a consumable receiving person, corresponding consumables in the intelligent consumable cabinet are issued, and when the consumables in the intelligent consumable cabinet need tobe replenished, a replenishment notice is sent, so that consumable replenishment can be carried out in time, automatic management of selling and recycling of consumables is achieved, and the hospitalmanagement cost is reduced.

Owner:医修技术服务(北京)有限公司

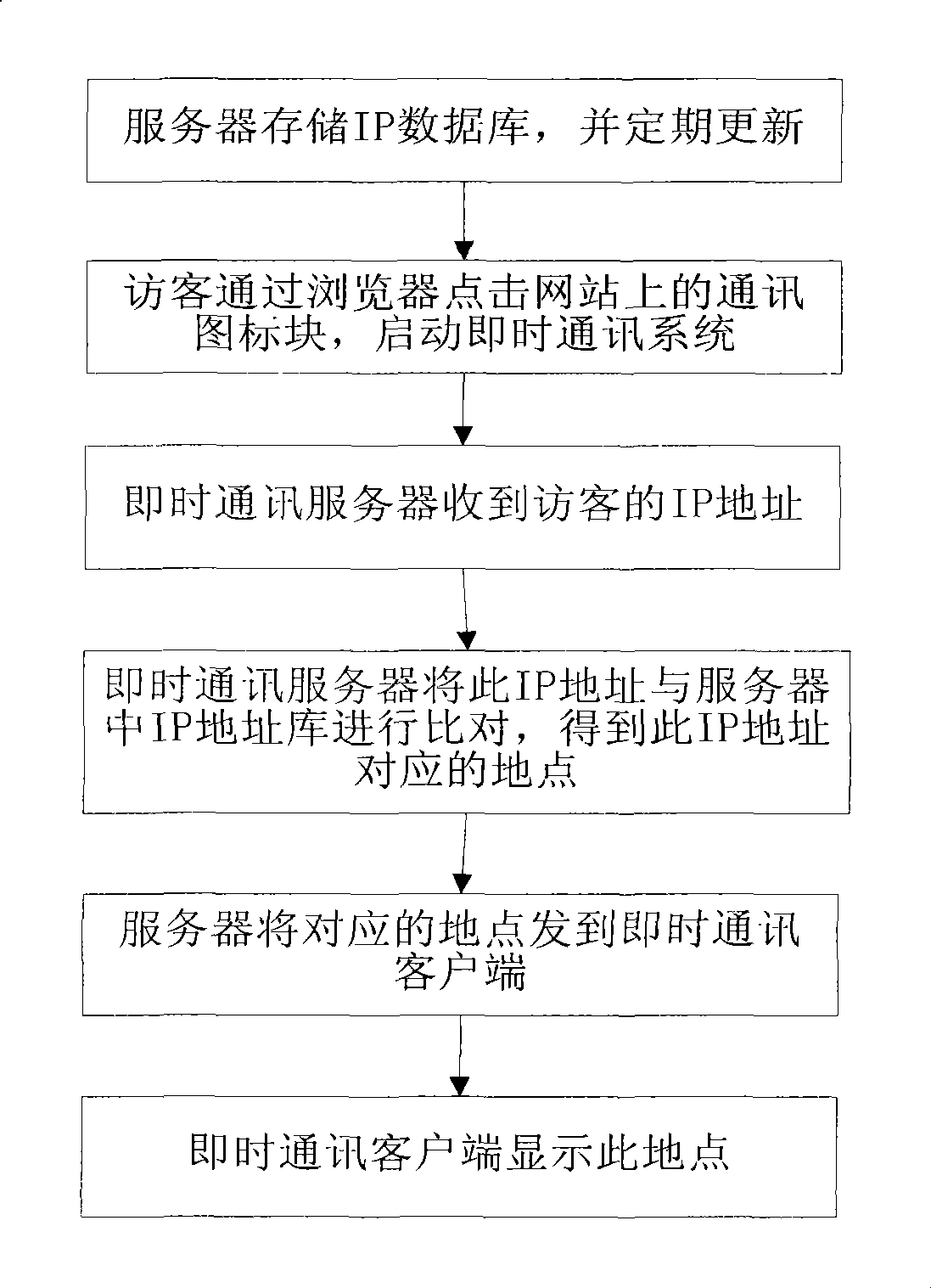

Method for determining Internet login location of visitor

InactiveCN101459624AAchieve salesData switching networksSpecial data processing applicationsCommunications systemIp address

The invention provides a method for assuring internet landing sites of visitors, which comprises storing IP address databases by a server, keeping frequently refreshing, clicking communication icon blocks on websites through a browser by a visitor, starting an instant communication system, catching IP address of the visitor through the instant communication server, comparing the IP address and IP address databases in the server by the instant communication server, getting the site which is corresponding to the IP address, and transmitting the corresponding site to an instant communication client end by the server. A website can timely and accurately confirm the internet landing site of a visitor by using the method, and the method can pertinently provide service, and archive sale.

Owner:BEIJING YIQI TELECOMM TECH

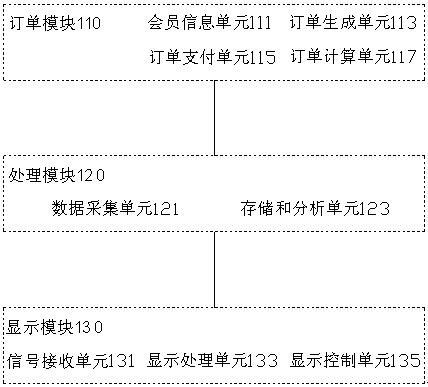

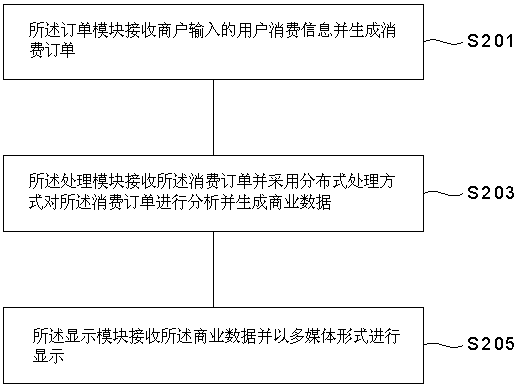

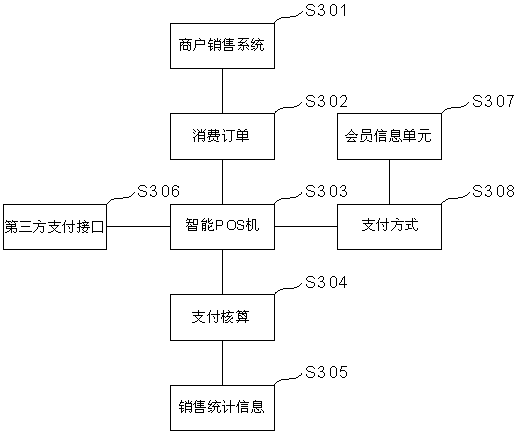

Business district management system and method

InactiveCN109993569AModernize the Buying ProcessAchieve salesBuying/selling/leasing transactionsMarket data gatheringPayment transactionButt joint

The invention discloses a business district management system and a method thereof, and relates to the field of Internet. The system comprises an order module which is used for receiving user consumption information input by a merchant and generating a consumption order, wherein each consumption order comprises payment amount information and sales statistics information of the user; a processing module which is used for receiving the consumption order, analyzing the consumption order by adopting a distributed architecture mode and generating commercial data; and a display module which is usedfor receiving the commercial data and displaying the commercial data in a multimedia form. Butt joint integration of merchant sales, payment transaction, intelligent payment and the like is achieved,big data collection, processing and display are carried out on order information, and support is provided for decision-making operation analysis.

Owner:上海长晓网络科技有限公司

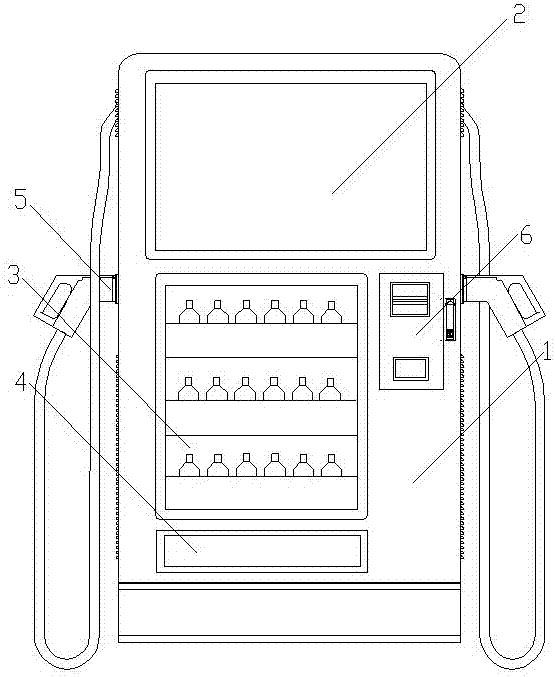

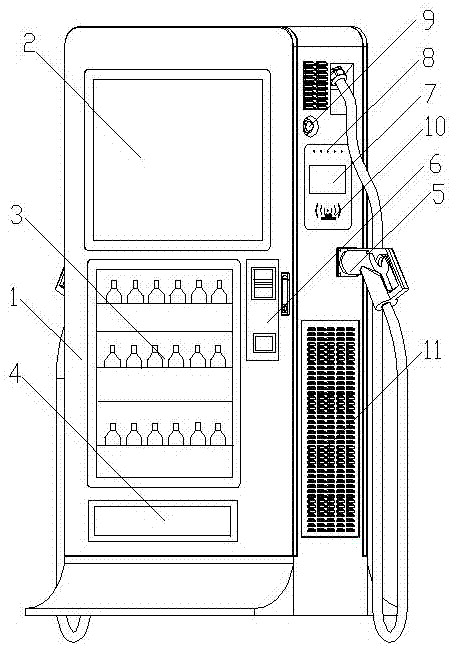

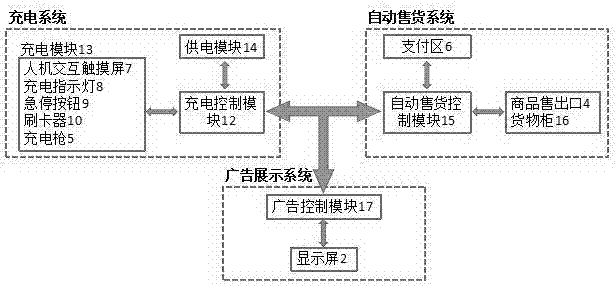

Multifunctional charging pile

InactiveCN107316392AAchieve salesAchieve diversificationCoin-freed apparatus detailsApparatus for hiring articlesPaymentComputer module

The invention discloses a multifunctional charging pile which comprises a charging system, an automatic vending system and an advertising display system. The charging system mainly comprises a case, a power supply module, a charging module and a charging control module, wherein the power supply module and the charging module are respectively connected with the charging control module. The automatic vending system comprises a commodity showing window, a commodity selling outlet, a payment zone and a vending control module, wherein a commodity cabinet is arranged in the commodity showing window, and the payment zone is connected with the vending control module. The advertising display system comprises a display screen and an advertising control module, wherein the display screen is connected with the advertising control module. The multifunctional charging pile has the advantages that the charging system, the automatic vending system and the advertising display system are organically integrated, the charging system can charge an electric automobile, the automatic vending system can achieve commodity selling, and the advertising display system can put advertisings for advertising customers so as to achieve diversified gaining.

Owner:深圳市国投创新科技有限公司

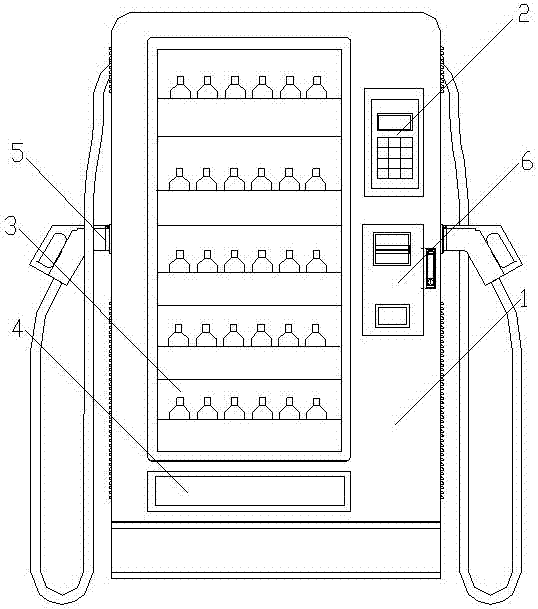

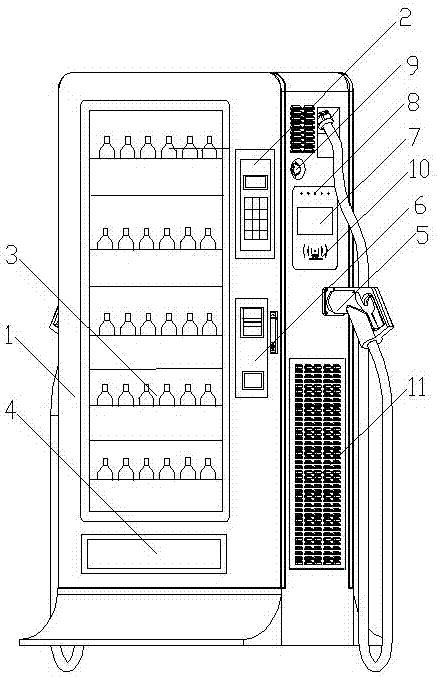

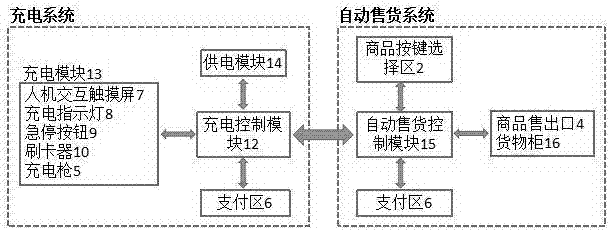

Charging pile with automatic vending system

InactiveCN107256592AAchieve salesAchieve diversificationCoin-freed apparatus detailsApparatus for hiring articlesPaymentKey pressing

The invention discloses a charging pile with an automatic vending system. The charging pile includes a charging system and the automatic vending system. The charging system mainly includes a case, a power supply module, a charging module, and a charging control module, wherein the power supply module and the charging module are connected to the charging control module. The automatic vending system includes a commodity display window, a commodity selling opening, a commodity key selection region, and a payment region; a goods cabinet is arranged in the commodity display window; and the key selection region and the payment region are connected to the automatic vending control module. The charging pile has the following advantages that the charging system and the automatic vending system are integrated, the charging system can charge an electric car, and the automatic vending system can sell commodities so as to achieve diversified profit.

Owner:深圳市国投创新科技有限公司

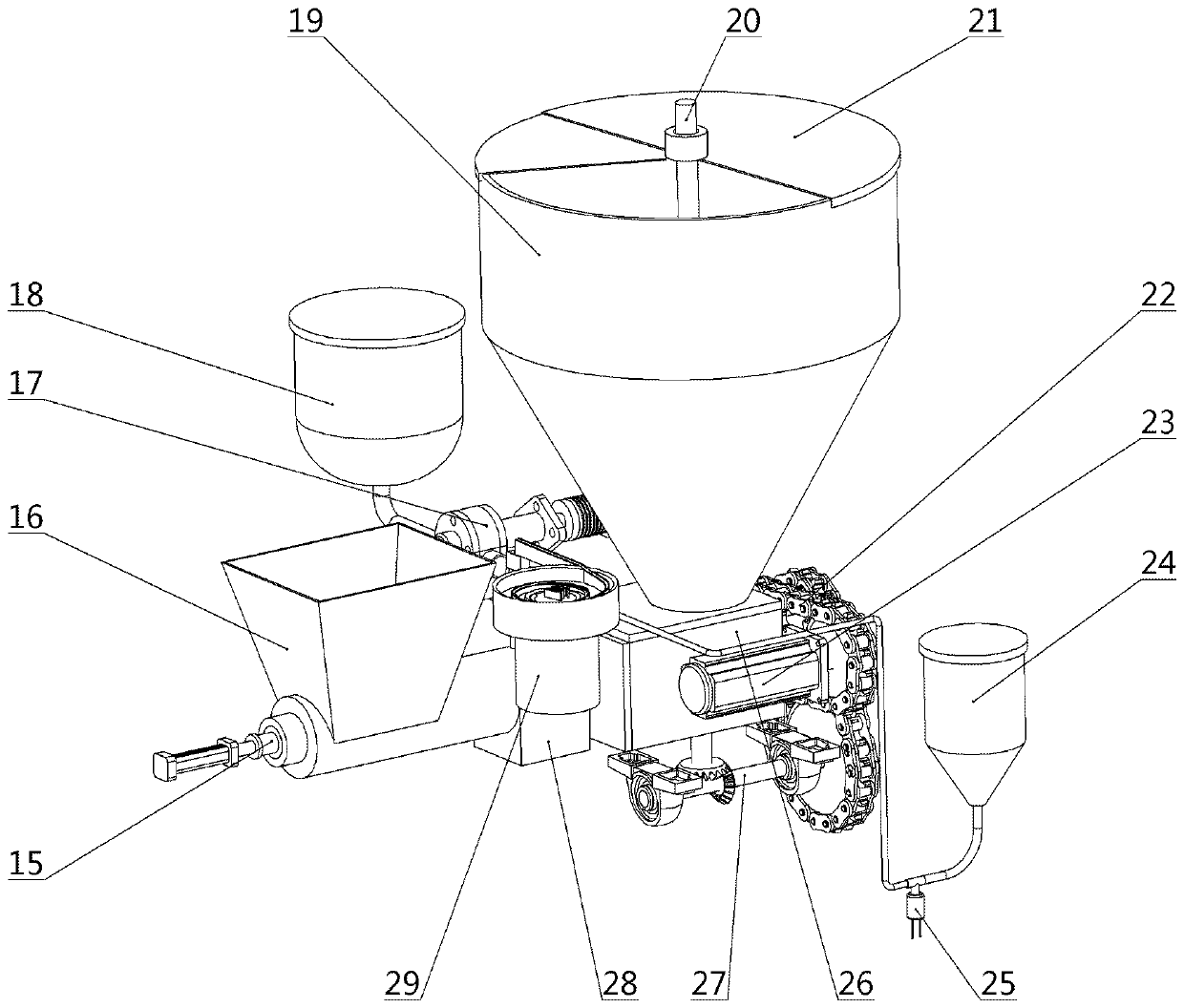

Automatic noodle cooking workstation and operation method

PendingCN111772486ASmooth rotationAutomatic bowl out quicklyConveyorsConveyor partsProcess engineeringIndustrial engineering

The invention discloses an automatic noodle cooking workstation and an operation method. A noodle cooking machine is arranged, an automatic bowl discharging machine is arranged on one side of the noodle cooking machine, a seasoning mechanism is arranged above the automatic bowl discharging machine, a swing mechanism is arranged in the automatic bowl discharging machine, a bowl moving mechanism isarranged behind the swing mechanism, a rotary conveying device is arranged at the upper end of the automatic bowl discharging machine, and a turnover mechanism is arranged on the noodle cooking machine. According to the automatic noodle cooking workstation, bowls are automatically lifted and dropped into the rotary conveying device through the bowl moving mechanism and then placed on the turnovermechanism, and automatic alignment of seasonings and quantitative addition of seasonings are achieved through the seasoning mechanism; all the devices can be automatically connected and matched, and through the control of the control screen, the situation of the machine can be mastered in real time, workers can conveniently monitor and maintain the machine, automatic noodle cooking and selling inthe whole process are achieved, labor is saved, and meanwhile, the product quality is guaranteed.

Owner:DONGGUAN KEYUE ELECTRONICS TECH

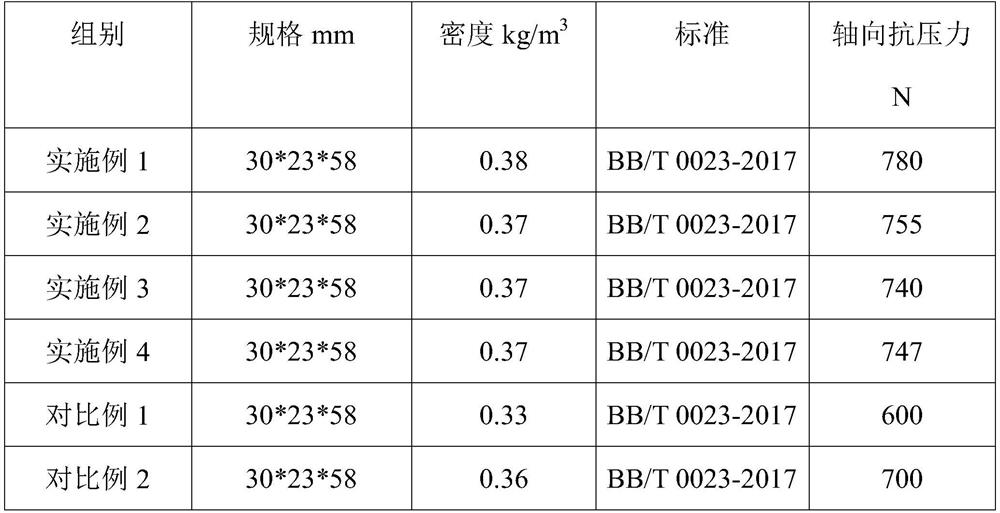

Naturally degradable polymeric material and preparation method thereof

The invention discloses a naturally degradable polymeric material and a preparation method thereof. The material is prepared from the following dry materials in parts by weight: 15-50% of starch, 1.5-5% of stearic acid, 5-15% of pine needle meal, 30-60% of plant fiber and / or waste paper scraps and 10-30% of fiber powder, wherein a mixing ratio of the dry materials to hot water is 1: (1.6-2.5). Plant environment-friendly raw materials and degradable materials are adopted and subjected to physical polymerization and gelatinization reactions at high temperature to prepare the naturally degradablepolymeric material; and the produced material is friendly to environment, low in cost and good in structural force and meets the use requirements of the packaging industry.

Owner:GUANGZHOU ZHI JIAN GENERAL EQUIP MFG CO LTD

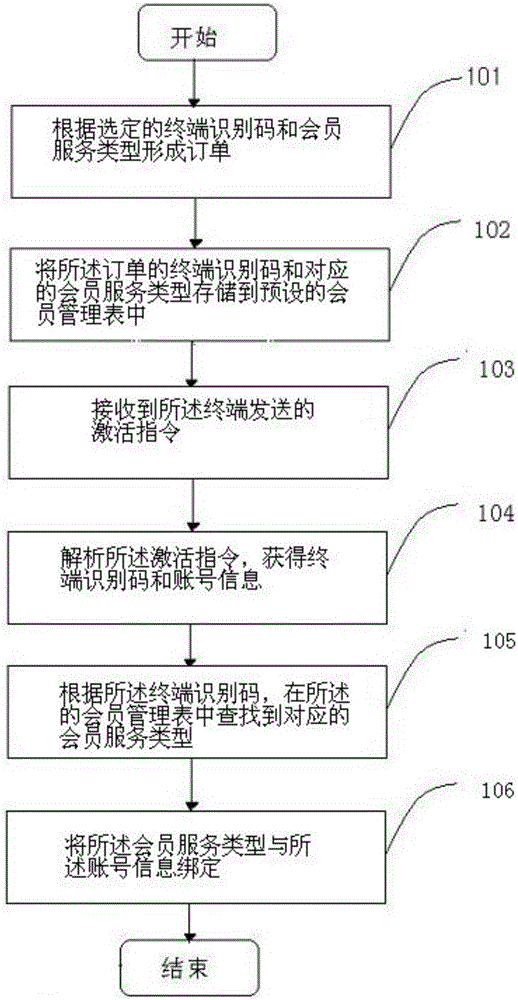

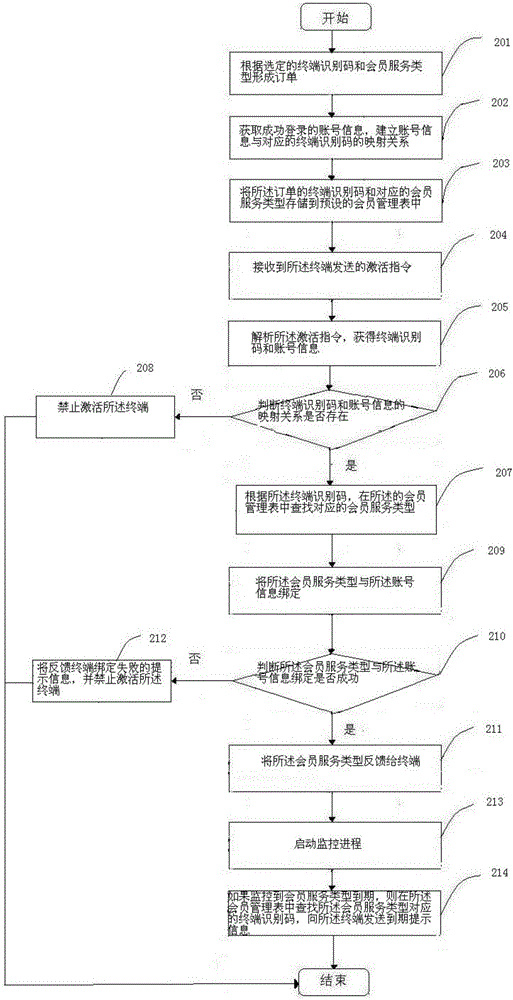

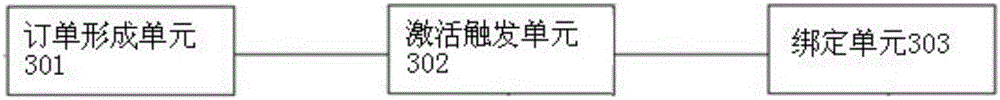

Method and device for selling terminals associated with member service

InactiveCN105894271AAchieve salesImplement authorizationMarketingProtocol authorisationSoftware engineeringComputer terminal

The invention discloses a method and device for selling terminals associated with member service. The method comprises steps of: forming an order according to a selected terminal identification code and a member service type and storing the terminal identification code of the order and the corresponding member service type in a preset member management list; analyzing, when an activation instruction sent from the terminal is received, the activation instruction to obtain the terminal identification code and account information; searching the corresponding member service type in the member management list according to the terminal identification code and binding the member service type to the account information. The method and device for selling terminals associated with member service may achieve card-free member service sale, authorization and activation, simpler operation, and better user experience.

Owner:LETV HLDG BEIJING CO LTD +1

Automatic mobile phone accessory sale equipment

InactiveCN107767547AAchieve recyclingAchieve salesAcutation objectsComputer compatibilityMobile phone

Automatic mobile phone accessory sale equipment comprises a shell and conveying systems. The conveying systems comprise the recovery conveying system and the delivery conveying system, a display roomis arranged in the shell, and a purchase opening is formed in the position, on the front end face of the shell, of one side of the display room; a detection panel and an indicator lamp are arranged atthe purchase opening, and the detection panel is provided with a cover plate and a detection port; an electronic screen is arranged at the lower end of the purchase opening, and a goods outlet is formed in the lower end of the electronic screen; a disinfection system is arranged at the lower end of the display room, and the disinfection system is connected with the purchase opening and the display room through the recycling conveying system separately; the display room is connected with the goods outlet through the delivery conveying system. The equipment can be compatible with mobile phone accessories of different types, and the compatibility can be improved according to development of the mobile phone accessories; the detection port and the purchase opening are integrated, so that validaccessories are prevented from being replaced with invalid accessories by a user to be recycled, and function diversity and humanization of the automatic mobile phone accessory sale equipment are achieved.

Owner:JIUJIANG UNIVERSITY

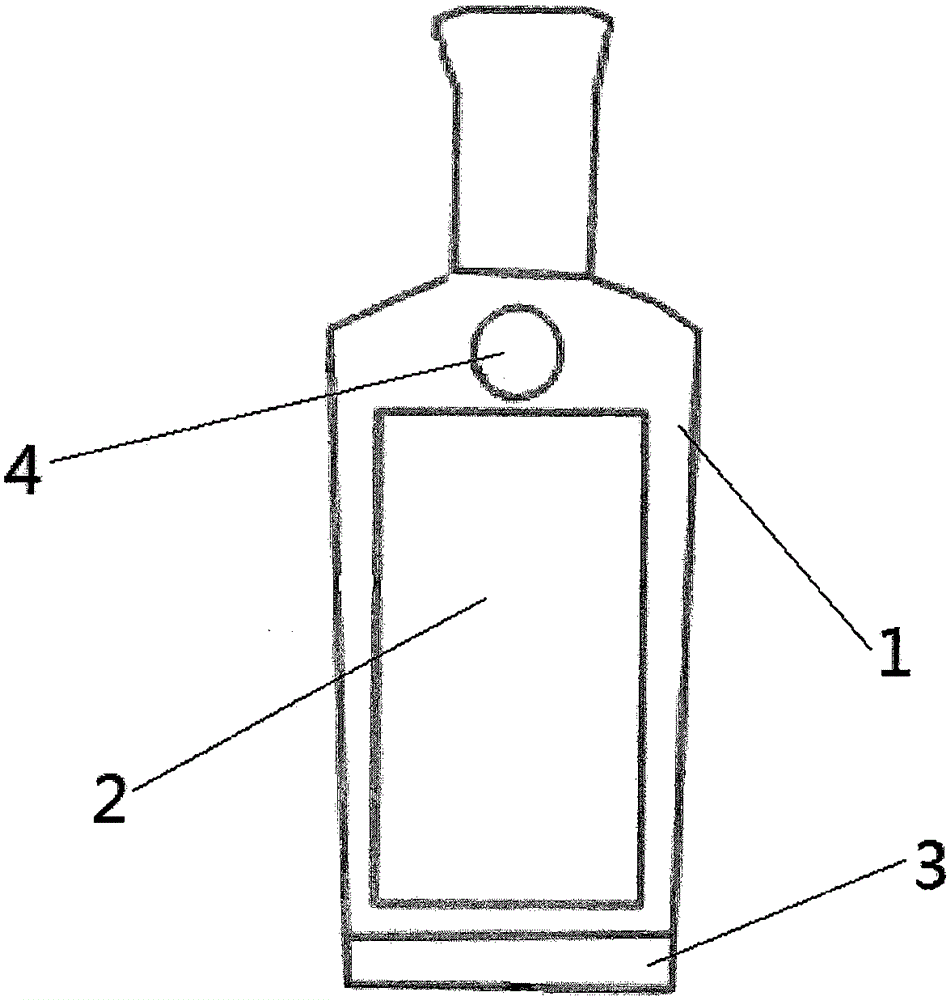

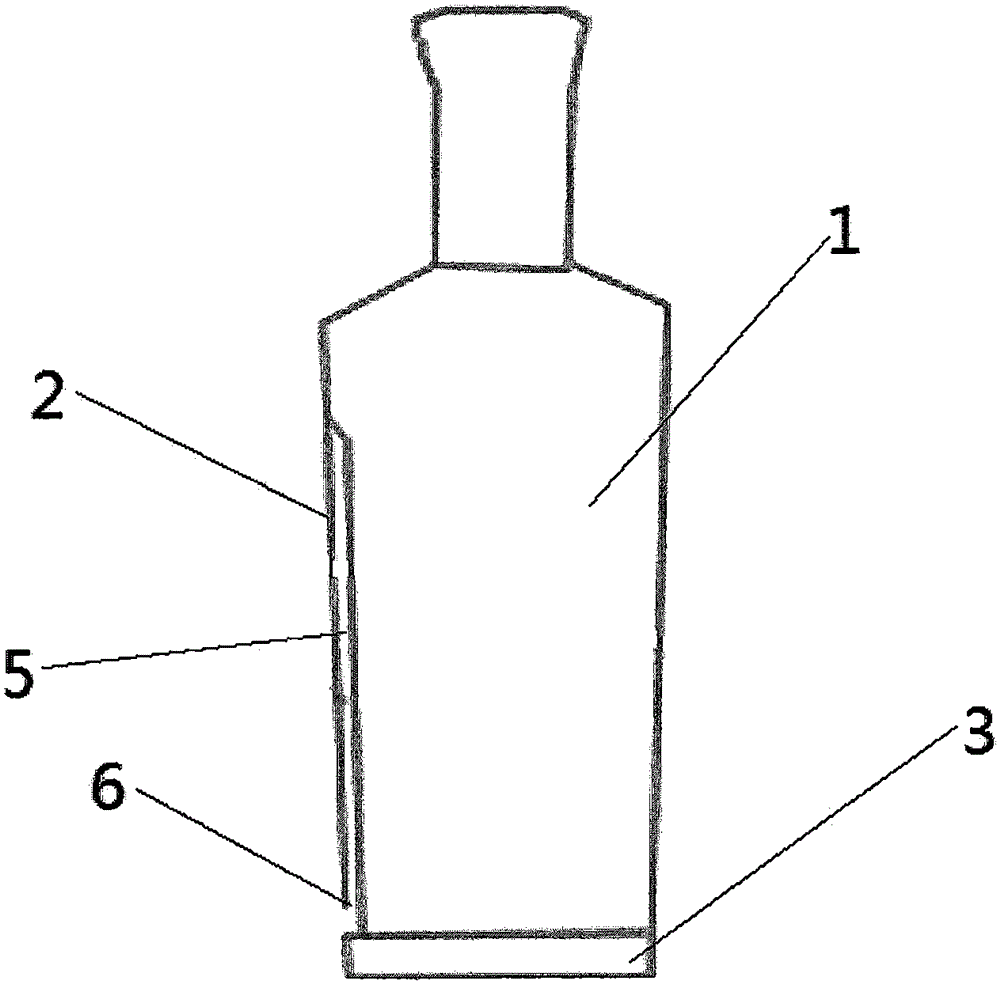

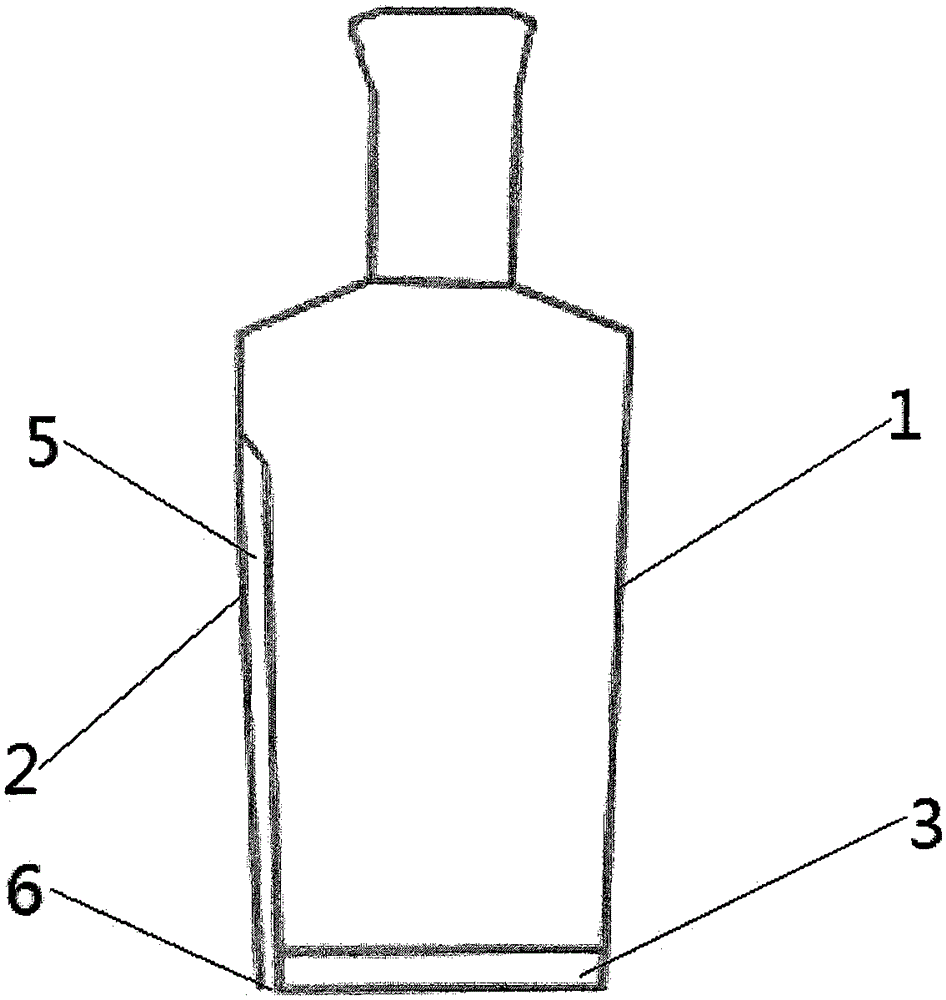

Personalized customization wine bottle

InactiveCN105236035AThe cost of customization is not highNo need to waitAttachment meansPersonalizationBiochemical engineering

The invention relates to a personalized customization wine bottle which comprises a bottle body (1) and a bottle base (3) integrated with the bottle body (1). A transparent clamping plate (2) is arranged on the outer side face of the bottle body (1). A hollow interlayer (5) is arranged between the transparent clamping plate (2) and the bottle body (1). An inlet (6) is formed in the lower portion of the hollow interlayer (5). Personalized customization content is contained in the hollow interlayer (5). A concave-convex clamping point is arranged around the inner side of the inlet (6), and the inlet (6) is sealed by a sealing strip in an embedded manner. According to the wine bottle, personalized customization wine becomes simple and easy, especially, no special personnel or equipment needs to be put, consumers can directly participate in design and manufacturing, personality can be completely shown, and the needs of different personal personnel can be met; and meanwhile cost is low, and the personalized customization content is not prone to falling off or being damaged.

Owner:陈再云

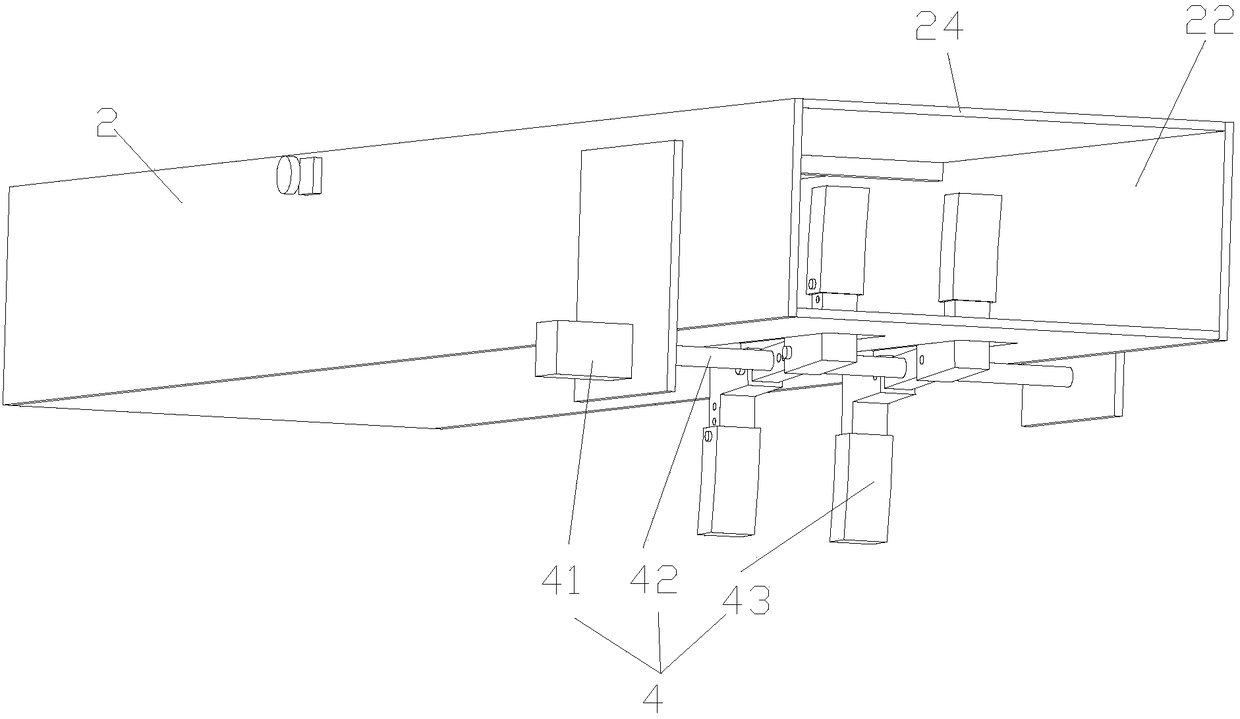

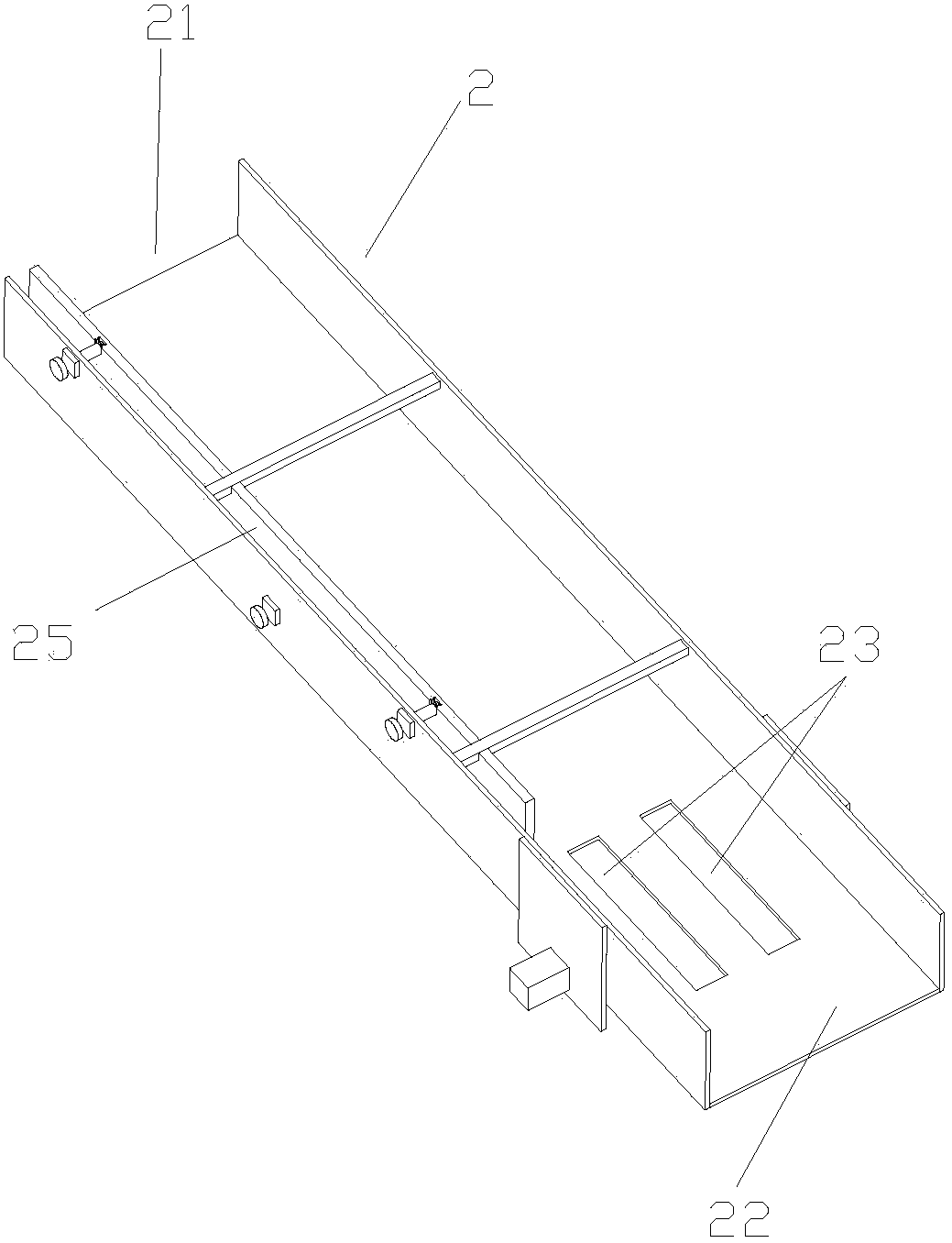

Comprehensive vending machine

ActiveCN108320384AAccurate single-out outputAccurate control of single-out outputCoin-freed apparatus detailsApparatus for dispensing discrete articlesBiochemical engineeringUtilization rate

The invention provides a comprehensive vending machine which comprises a tank body, wherein a storage zone and a taking zone are arranged inside the tank body; at least one storage trough which is inclined towards a taking direction is formed in the storage zone; a taking trough is formed in the taking zone; a feeding hole is formed in the left end of the first storage trough; a discharge hole isformed in the right end of the first storage trough; a first control device capable of controlling single output of cargos is arranged close to the discharge hole in the first storage trough; the first control device comprises a first driving device, a first rotating shaft and at least one clamping claw; the first driving device is in driving connection with the first rotating shaft; the first rotating shaft is sleeved by the clamping claw; the clamping claw comprises at least two clamping strips which are uniformly distributed around the center of the first rotating shaft; a first avoiding part for avoiding the clamping claw is arranged at the bottom of the first storage trough. The comprehensive vending machine is simple in structure, high in space utilization rate, rapid in cargo replenishing efficiency and simple and convenient to repair.

Owner:惠州市优侎实业有限公司

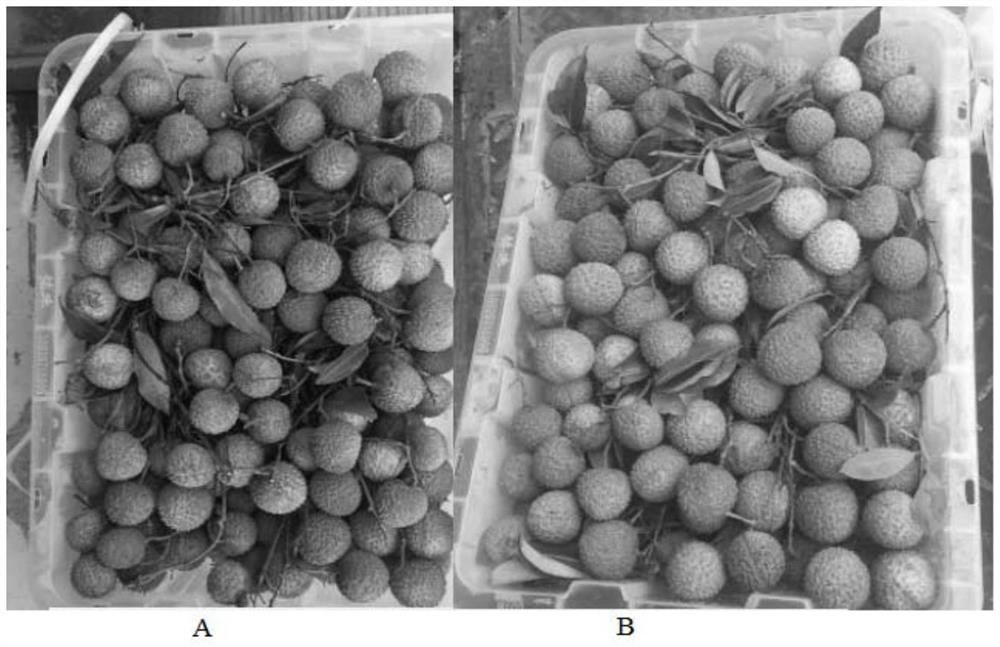

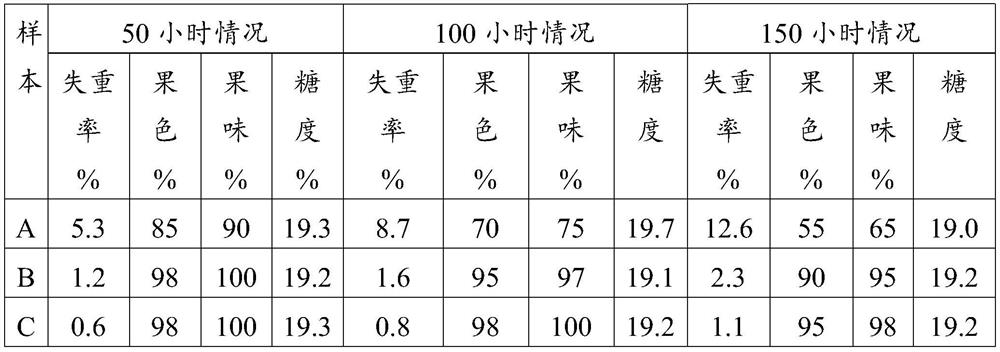

Storage, transportation and preservation method for e-commerce sold litchis

PendingCN112006090AGuaranteed freshnessMaintain quality flavorFruits/vegetable preservation by freezing/coolingAgricultural scienceLychee fruit

The invention relates to a storage, transportation and preservation method for e-commerce sold litchis, and belongs to the technical field of fruit and vegetable preservation. The storage, transportation and preservation method for the e-commerce sold litchis provided by the invention comprises the steps of harvesting, sorting and cooling treatment after harvesting, refrigeration and preservation,and long-distance transportation. According to the storage, transportation and preservation method for the e-commerce sold litchis provided by the invention, the original quality and flavour of litchis can be maintained; the rotting rate is reduced; the product sales distance is increased; the customer market is widened; the economic benefit is improved; the storage and transportation period is prolonged; the quality of litchi fruits is still not influenced after 450 h of storage and transportation; due to the e-commerce sale, the after-sales compensation rate is lower than 0.5%; and the commodity loss is reduced.

Owner:茂名乐穗农业科技有限公司 +4

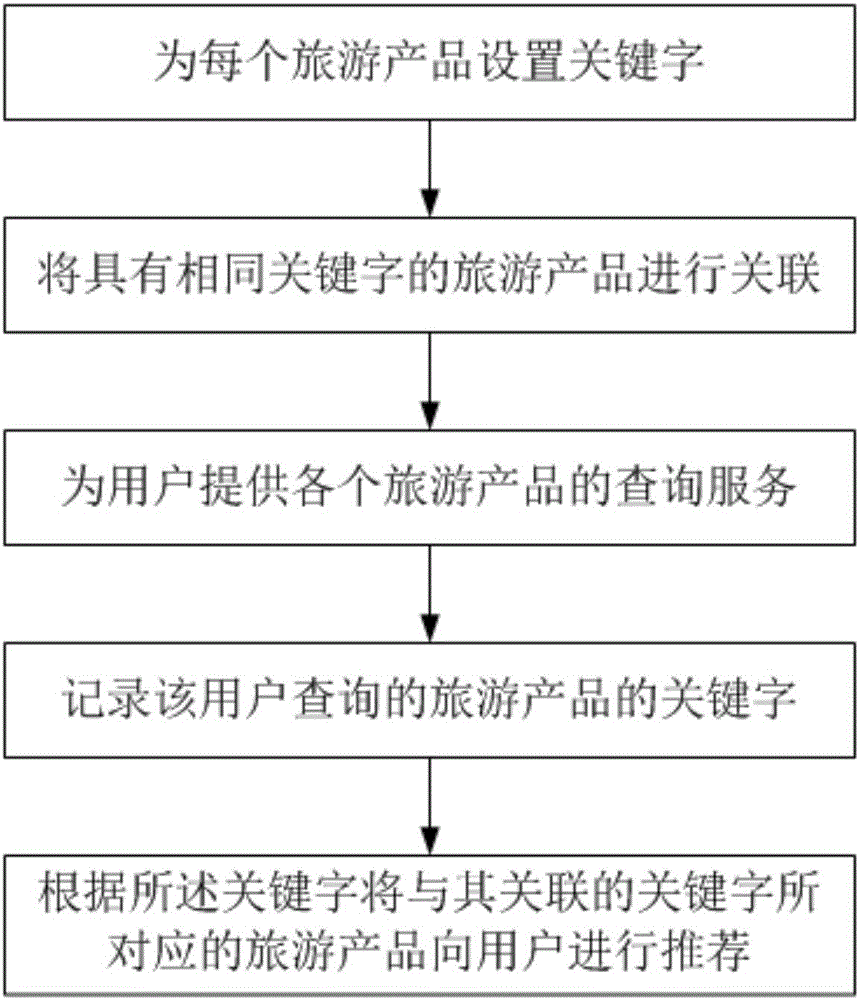

Travel information processing system and processing method

InactiveCN106372131AReduce query timeIncrease salesData processing applicationsWeb data indexingInformation processingWeb site

The invention provides a travel information processing system and method. The method comprises the steps of setting a keyword for each travel product; associating travel products with same keywords; providing a query service of each travel product for a user; recording the keyword of the travel product queried by the user; and recommending a travel product corresponding to a keyword associated with the keyword to the user according to the keyword. According to the travel information processing system and method, the travel product corresponding to the pre-stored keyword associated with the keyword can be recommended to the user through the keyword of the travel product queried by the user, so that a travel route is quickly recommended to a tourist intelligently according to a preference of the tourist, the query time is shortened for the tourist, and the sales rate of a travel website is increased.

Owner:广西小草信息产业有限责任公司

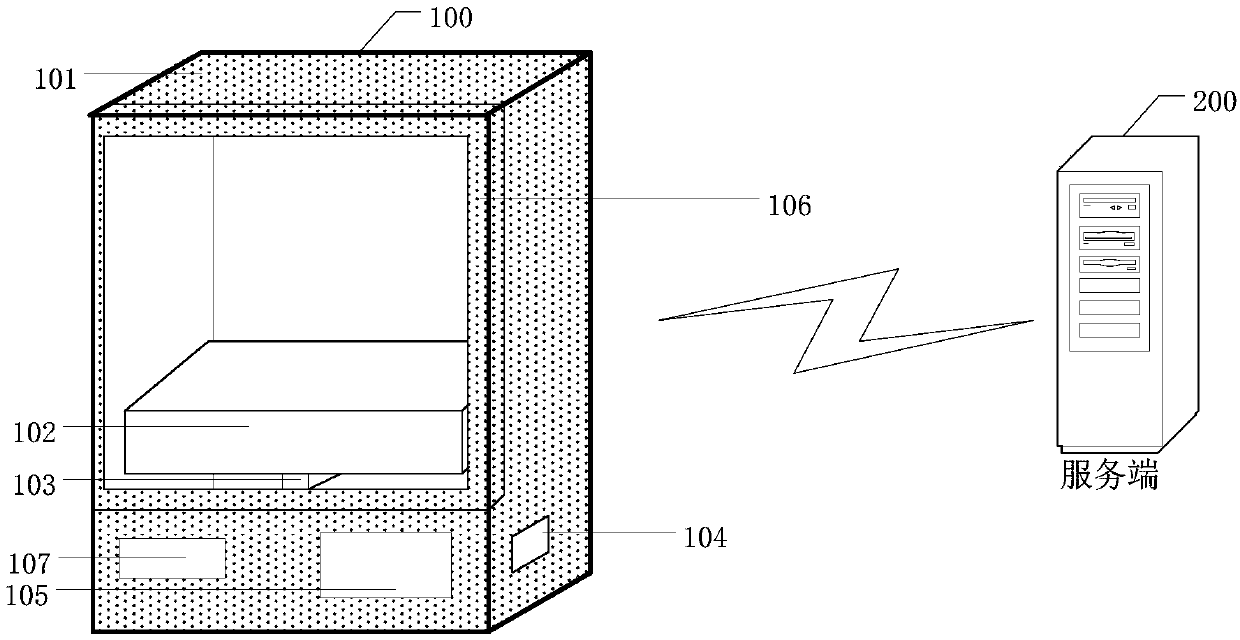

Weighing system and automatic vending system

PendingCN109523698AAchieve salesCoin-freed apparatus detailsTransmissionEngineeringMechanical engineering

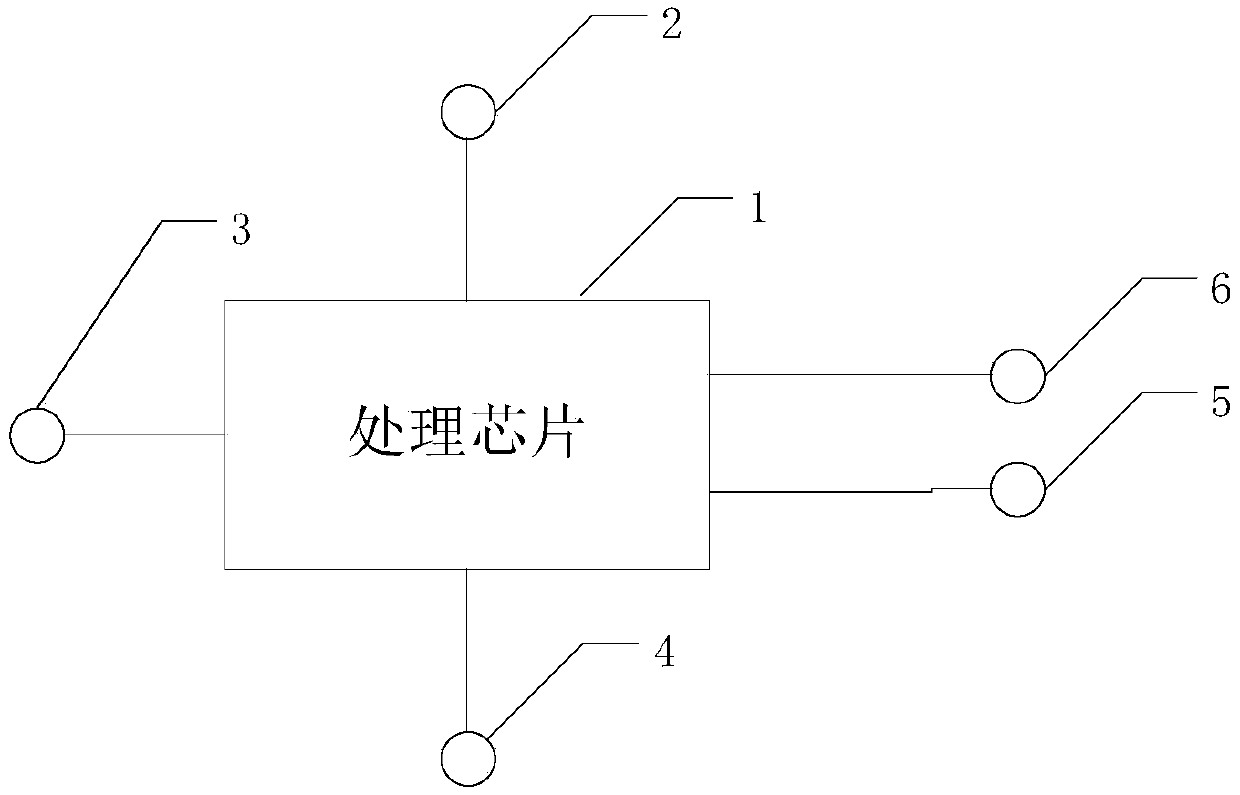

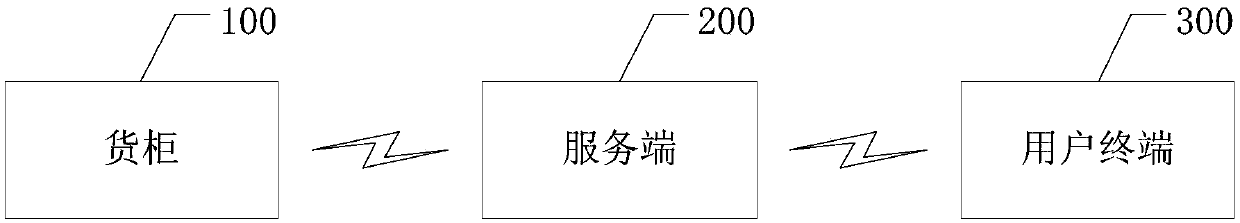

The invention discloses a weighing system and an automatic vending system. The weighing system includes a container and a service end, wherein the container includes a container body, a load bearing component, a force transmission conversion module, a network communication module, an operation control module and an electronic control door mounted on the container body, the load bearing component is located in the container body, the load bearing component is used for disposing goods for sale, the force transmission conversion module is used for detecting the weight information of the goods forsale held by the load bearing component, the network communication module is used for communicating with the service end, the operation control module is connected with the network communication module, the electronic control door and the force transmission conversion module, and the service end is used for sending a door opening instruction to the container according to a door opening request sent by a user through a user terminal. The weighing system is advantaged in that sale of goods by weight can be realized.

Owner:王立强

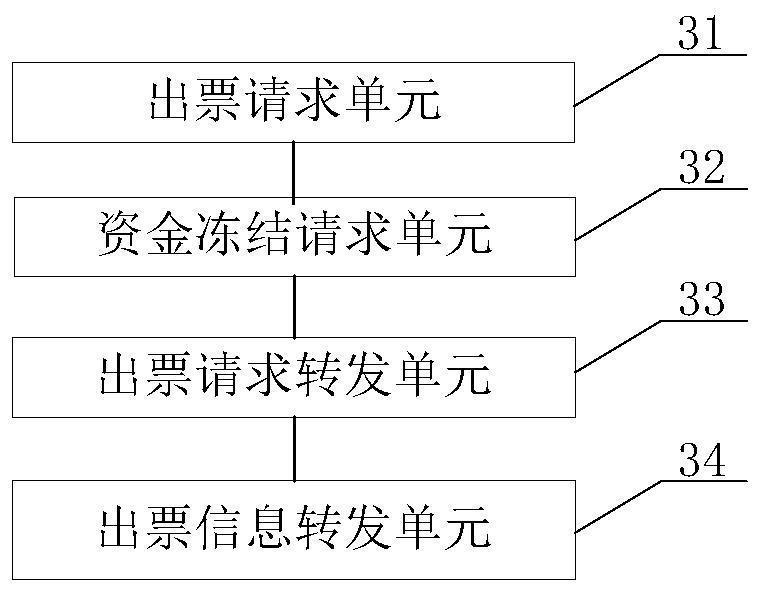

BOP payment settlement method, device and equipment, and readable storage medium

PendingCN112232789AImprove user experienceIncrease access rateBuying/selling/leasing transactionsProtocol authorisationPaymentDatabase

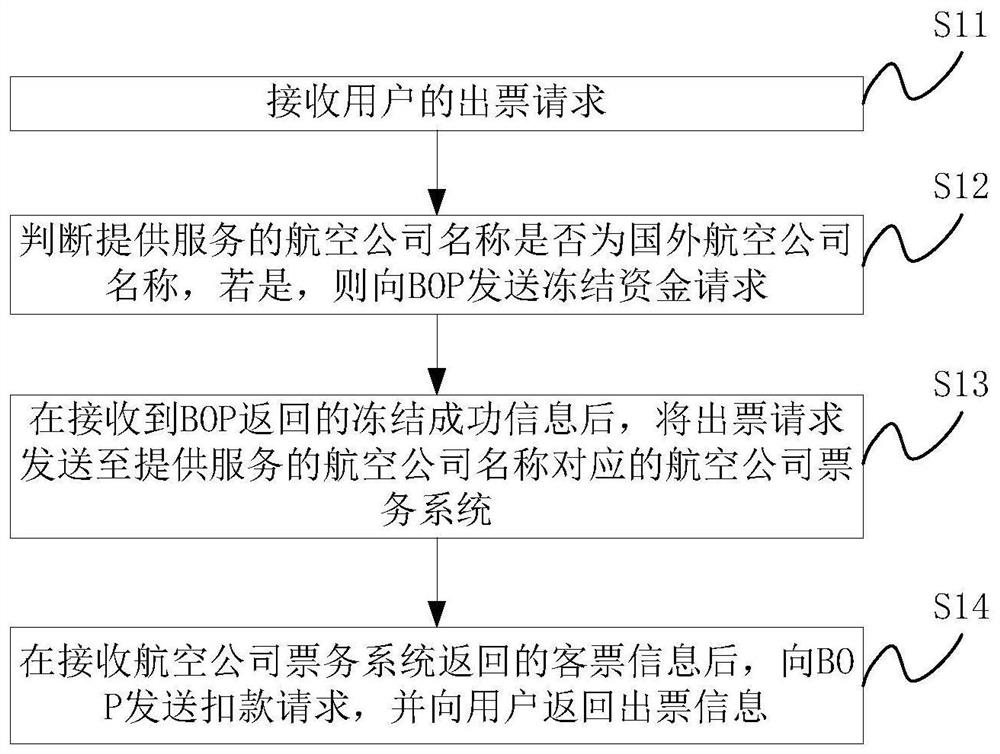

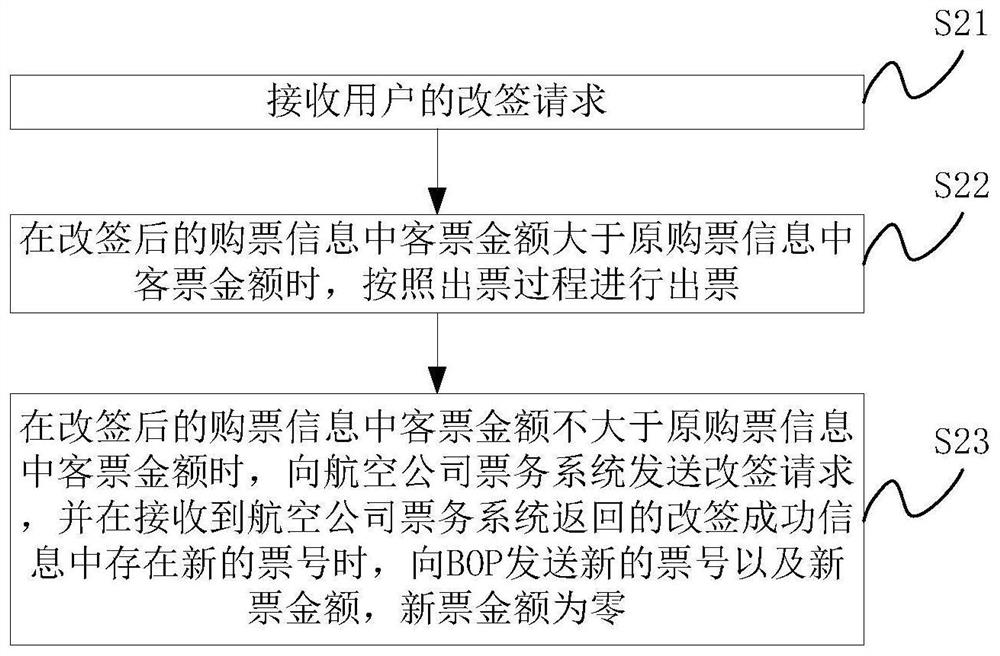

The invention provides a BOP payment settlement method, device and equipment and a readable storage medium, and the method comprises the steps that when an agent in a Chinese mainland region applies to a foreign airline ticket business system for ticket issuing through an NDC content aggregation platform, the foreign airline ticket business system issues a ticket from a ticket number segment provided by a BOP for the foreign airline ticket business system; and a fund freezing request is sent to the BOP before the ticket is issued, so as to freeze the corresponding fund from the BOP account ofthe user, and the frozen fund is deduced after the ticket is successfully issued. Through the BOP payment settlement scheme provided by the invention, the domestic BSP passenger ticket sales of foreign airlines is realized. The whole payment and settlement process is completely unperceived by the user, the use experience of the user is improved, and the access rate of the user is further improved.

Owner:TRAVELSKY

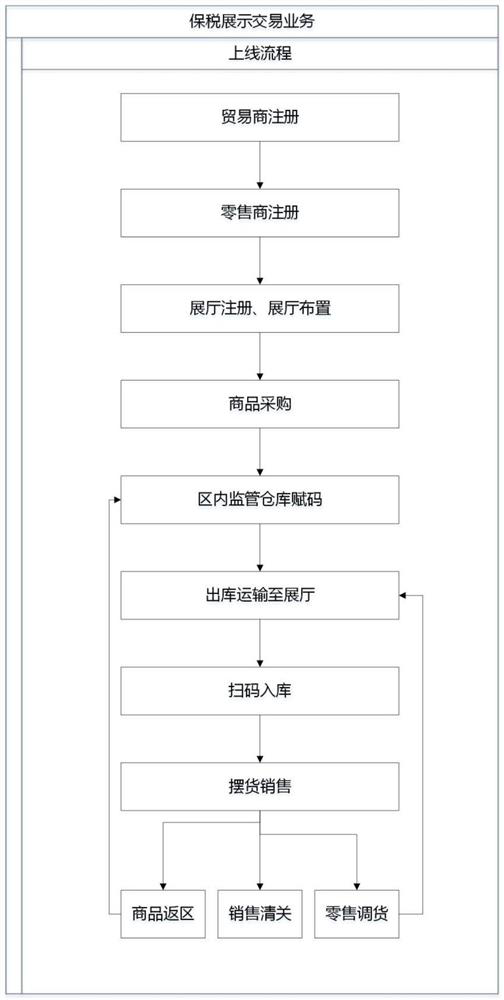

Block chain-based display and transaction method and system for tax-warranted commodities

PendingCN114331642ARealize displayAchieve salesFinanceBuying/selling/leasing transactionsBlockchainOperating system

The invention discloses a display transaction method and system of tax-warranted commodities based on a block chain, and relates to the technical field of tax-warranted commodity supervision, and the method comprises the steps: collecting imported customs declaration information, carrying out a block chain process, endowing the information with a two-dimensional code, and storing the information in a system; commodities can be traced in real time through a system page, and commodity information can be checked by scanning a two-dimensional code; the two-dimensional code cannot be reused and can automatically lose efficacy after being torn down, so that the condition of inaccurate information is prevented; the commodity pasted with the two-dimensional code can go out of the taxation area for tax exemption, display transaction is carried out in an exhibition hall, and the retailer pays tax after the transaction is completed. According to the invention, the commodity can be delivered out of the area without tax and paid tax after the transaction is completed, so that the tax-guaranteed commodity can be managed and the display transaction can be opened, the supervision of customs is facilitated, and the pressure of enterprises is reduced.

Owner:浪潮海链易贸(山东)信息科技有限公司

Multifunctional vending machine

InactiveCN108831025AAchieve salesAchieve crawlingCoin-freed apparatus detailsApparatus for dispensing discrete articlesOperations managementStorage area

The invention discloses a multifunctional vending machine. The vending machine comprises an operating panel, a goods storage area and a goods outlet device; the vending machine further comprises a goods grabbing area and a goods grabbing device, the operating panel is arranged on the outer surface of the multifunctional vending machine, and the goods storage area and the goods grabbing area are arranged side by side or stacked; the goods outlet device is arranged in the goods storage area and used for sending out goods; the operating panel comprises a goods selling operating device and a grabbing operating device, the goods selling operating device is used for shopping operation, and the grabbing operating device is used for operating the goods grabbing device to grab the goods in the goods grabbing area. By means of the multifunctional vending machine, the vending machine can achieve both functions of selling and grabbing the goods, and the same operating panel can be utilized for conducting online and / or offline operation to sell and / or grab the goods.

Owner:SUZHOU ZHONGKE ADVANCED TECH RES INST CO LTD +1

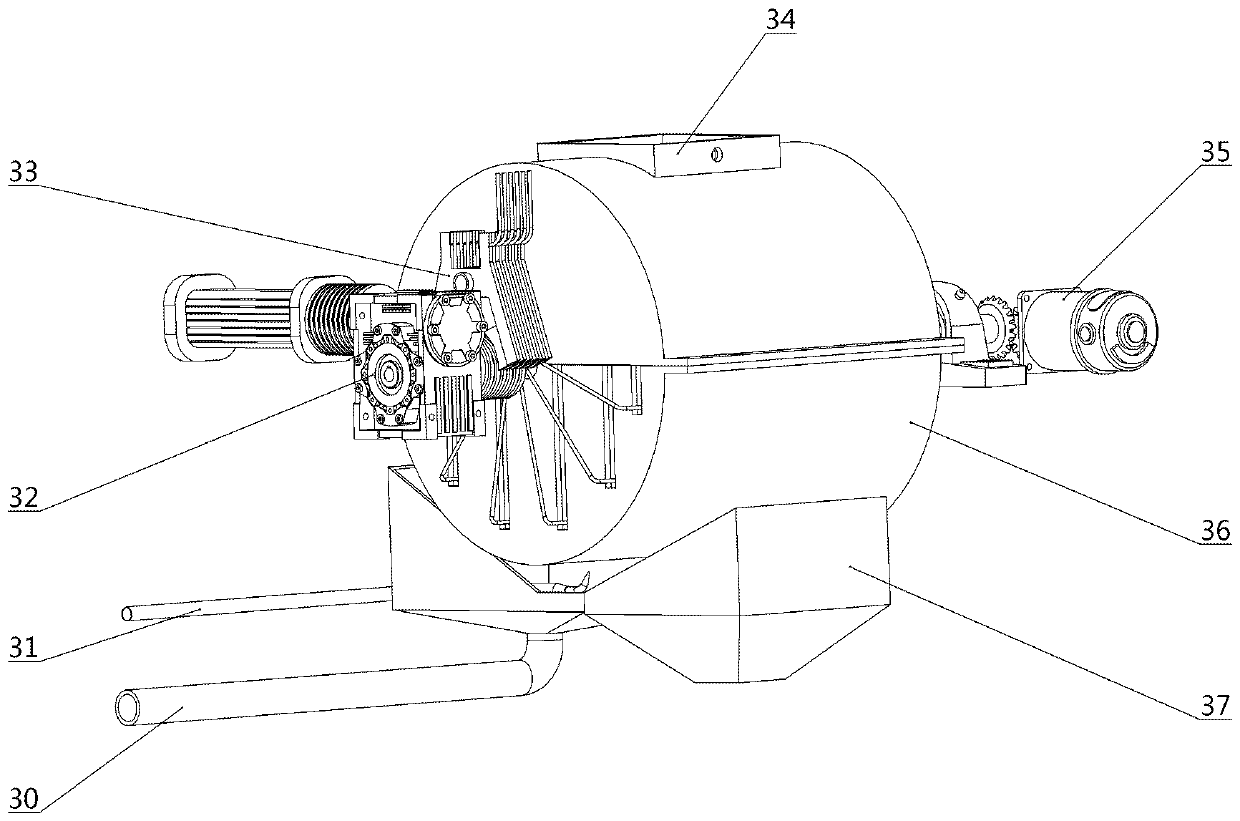

On-site intelligent production and sales system of multi-category fresh foods

InactiveCN109785516ASmooth and even dischargeResolve discontinuityCoin-freed apparatus detailsApparatus for meter-controlled dispensingWater bathsInjection port

The invention relates to an on-site intelligent production and sales system of multi-category fresh foods. The on-site intelligent production and sales system of the multi-category fresh foods comprises a main material automatic feeding device, an auxiliary material conveying device, an edible oil conveying device, a liquid auxiliary material (such as egg liquid, etc.) conveying device, a salt vibration conveying plate, a rotary type intelligent stir-fry device, a double-layer rotating disc type multi-category automatic packaging and selling device, and a water bath type heating and heat preservation quantitative conveying device; the main material automatic feeding device and the auxiliary material conveying device use one discharge port; the edible oil conveying device, the liquid auxiliary material conveying device and a salt vibration conveying plate injection port are arranged above the discharge port, and are located directly above the rotary type intelligent stir-fry device; thedouble-layer rotating disc type multi-category automatic packaging and selling device is located below a stir-fry canister mouth; and the water bath type heating and heat preservation quantitative conveying device is located on the right side of a main material canister. The invention can realize the instant heating, stir-frying and packaging sales of the fried rice food, can realize the heat preservation transportation and packaging sales of the porridge food, and belongs to the field of food processing and sale.

Owner:王建忠 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com