Naturally degradable polymeric material and preparation method thereof

A kind of polymer material and natural technology, applied in the field of packaging, can solve the problems of unguaranteed quality, high cost of use, heavy workload, etc., and achieve the effect of improving resource utilization, simple process, and good structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

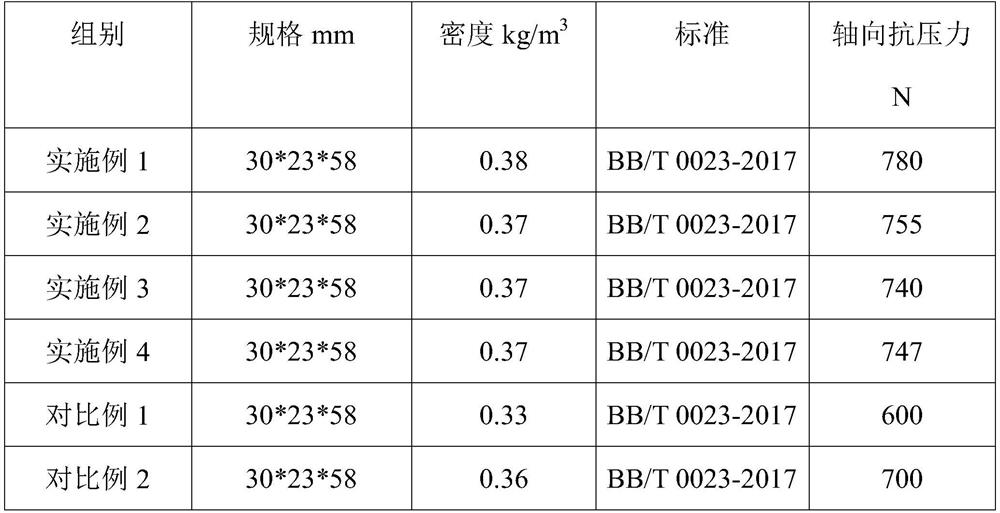

Examples

Embodiment 1

[0027] A naturally degradable polymeric tubing product, made of a naturally degradable polymeric material, consisting of the following dry materials in parts by weight:

[0028] Tapioca starch 100g (27.8%), stearic acid 7.5g (2.1%), pine needle powder 22g (6.1%), straw 130g (36.2%) and the powder 100g (27.8%) after secondary pulverization of MDF leftovers, dry The mixing ratio of raw materials and hot water is 1:2. The amount of hot water used is for a temperature of 100°C. Among them, the length of the straw is 1.5 mm, the diameter is 0.1 mm, and the size is 50 mesh; the size of the powder after secondary crushing of the MDF leftovers is 180 mesh.

[0029] A method for preparing a naturally degradable polymer tube, comprising the following steps:

[0030] 1) Put starch, stearic acid, pine needle powder, straw and MDF leftover powder into the mixer, and stir for 30 minutes in forward and reverse cycles;

[0031] 2) Add hot water while stirring in the mixer, stir in forward ...

Embodiment 2

[0034] A naturally degradable polymeric tubing product, made of a naturally degradable polymeric material, consisting of the following dry materials in parts by weight:

[0035] Cornstarch 110.3g (50%), stearic acid 11g (5%), pine needle powder 11g (5%), rice bran 66.2g (30%) and the powder 22.1g ( 10%), the mixing ratio of dry material and hot water is 1:1.6. The temperature of the hot water is 94°C. Among them, the length of the rice bran is 1mm, the diameter is 0.01mm, and the size is 30 mesh; the size of the powder after secondary crushing of the MDF leftovers is 80 mesh.

[0036] A method for preparing a naturally degradable polymer pipe product, comprising the following steps:

[0037] 1) Put starch, stearic acid, pine needles, rice bran, and waste and defective MDF powder into the mixer, and stir for 15 to 30 minutes in forward and reverse cycles;

[0038] 2) Add hot water while stirring in the mixer, stir in forward and reverse cycles until the dry material is compl...

Embodiment 3

[0041] A naturally degradable polymeric tubing product, made of a naturally degradable polymeric material, consisting of the following dry materials in parts by weight:

[0042] Cornstarch 45.3g (15%), stearic acid 4.5g (1.5%), pine needle powder 15.1g (5%), bamboo 181.2g (60%) and powder 55.9g after the second crushing of MDF waste and defective products (18.5%), the mixing ratio of dry material and hot water is 1:2.5. The temperature of the hot water is 98°C. Among them, the length of the bamboo is 1.2 mm, the diameter is 0.05 mm, and the size is 30 mesh; the size of the powder after the second crushing of the MDF leftovers is 100 mesh.

[0043] A method for preparing a naturally degradable polymer pipe product, comprising the following steps:

[0044] 1) Put the powder of starch, stearic acid, pine needle powder, bamboo and MDF waste and defective products into the mixer after secondary crushing, and stir for 20 minutes in forward and reverse cycles;

[0045] 2) Add hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com