Automatic noodle cooking workstation and operation method

A workstation and automatic technology, applied to the structure of cooking utensils, cooking utensils, transportation and packaging, etc., can solve the problems of waste of labor, lack of labor, high labor intensity, etc., to facilitate monitoring and maintenance, increase the stress area, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

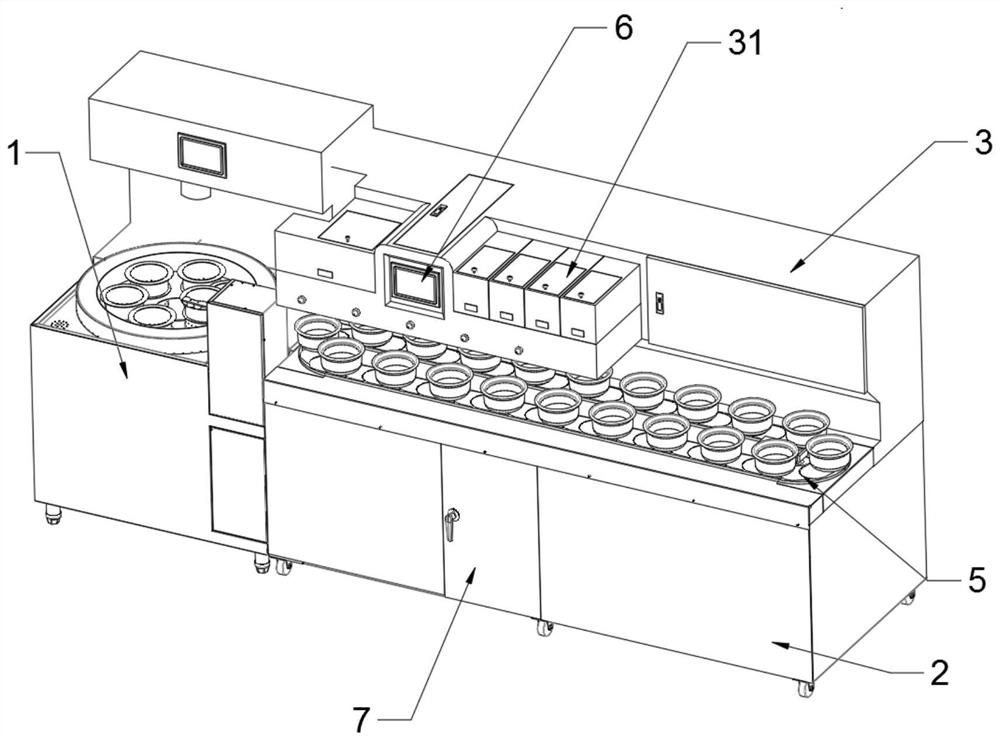

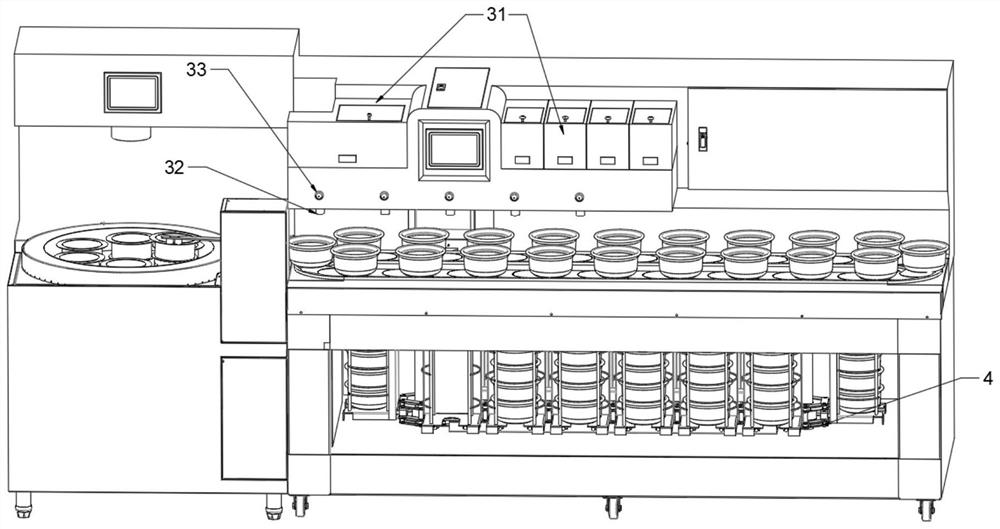

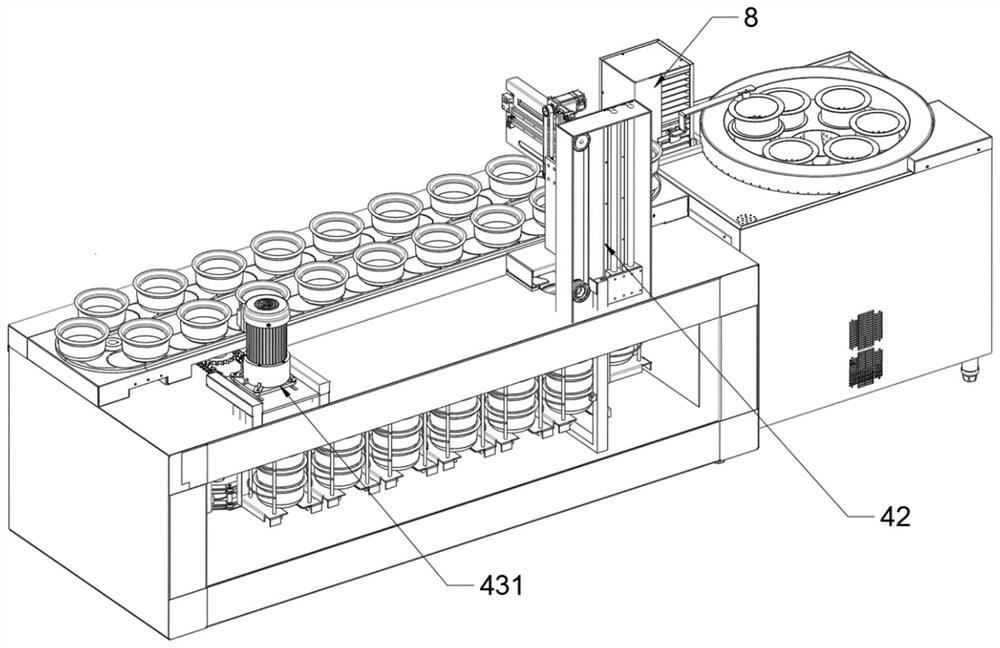

[0045] Examples, as attached Figures 1 to 20 The shown automatic noodle cooking workstation is provided with a noodle cooker 1, an automatic bowl dispenser 2 is provided on one side of the noodle cooker 1, a batching mechanism 3 is arranged above the automatic bowl dispenser 2, and the inside of the automatic bowl dispenser 2 is A rotary mechanism 4 is provided, the rear of the rotary mechanism 4 is provided with a bowl moving mechanism 42, the upper end of the automatic bowl machine 2 is provided with a rotary transmission device 5, and the noodle cooker 1 is provided with an overturning mechanism 8.

[0046] Slewing mechanism 4 is provided with two-layer transmission chain 421, and one side in the middle of transmission chain 421 is provided with driving transmission shaft 423, and the other side is provided with transmission transmission shaft 4231, and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com