Forming method of modular arc-shaped lamp housing

A modular and arc-shaped technology, applied in the direction of illuminated signs, instruments, display devices, etc., can solve the problems such as the inability to realize shadowless splicing, and achieve the effect of improving heat dissipation, beautiful appearance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution in the embodiment of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiment of the construction method of a modular arc light box of the present invention.

[0033] The front side and the rear side described in this embodiment are based on the front side and the rear side described in the accompanying drawings.

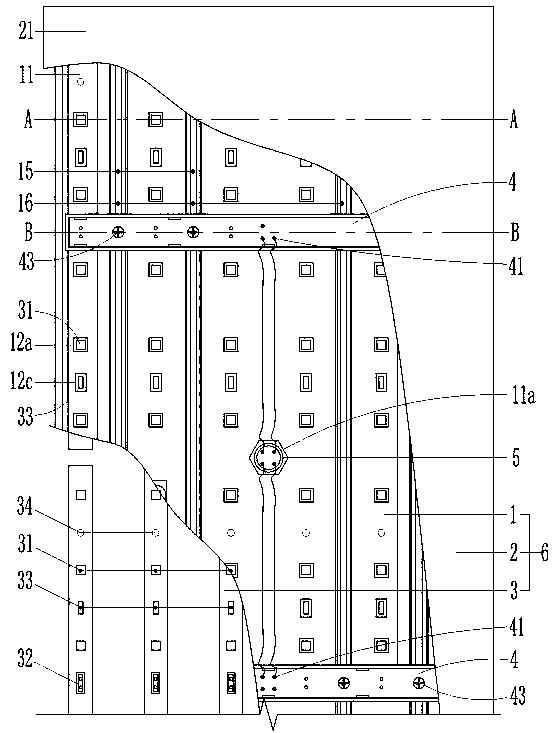

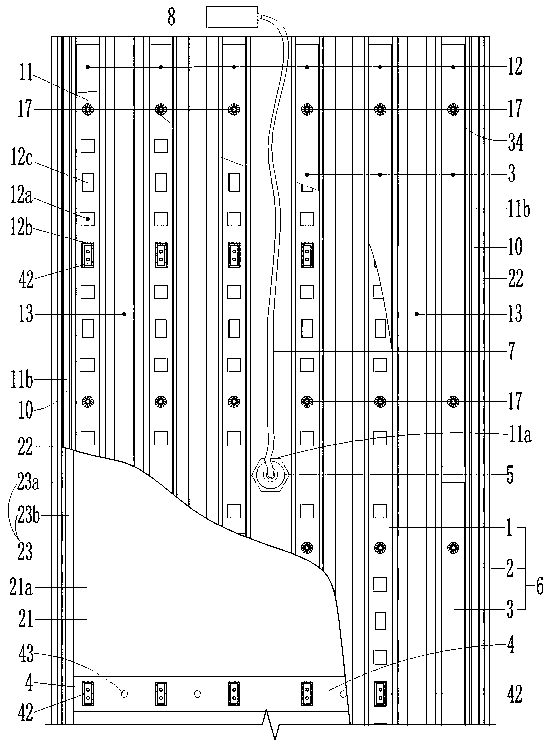

[0034] The embodiment of the method for forming the modular arc light box of the present invention, please refer to the attached figure 1 . like Figure 2 to Figure 5 As shown, first, a strip-shaped support shell 1 installed with a mask and a light bar, a mask 2 installed on the front side of the support shell 1, and a light bar 3 installed on the back side of the support shell 1 form a Strip backlight module6. The above-mentioned supporting shell 1 is a kind of light groove 12 on the rear side of the shell, and a fixed slot on the rear side of the shell base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com