A transfer structure and a connector comprising the transfer structure

A technology of connectors and main connections, which is applied in the direction of connection, parts of connection devices, contact parts, etc., can solve the problems of error-prone wiring relationships and low production efficiency, and achieve the benefits of wiring arrangement and increasing electrical clearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Embodiment 1 is a specific implementation of the transfer structure.

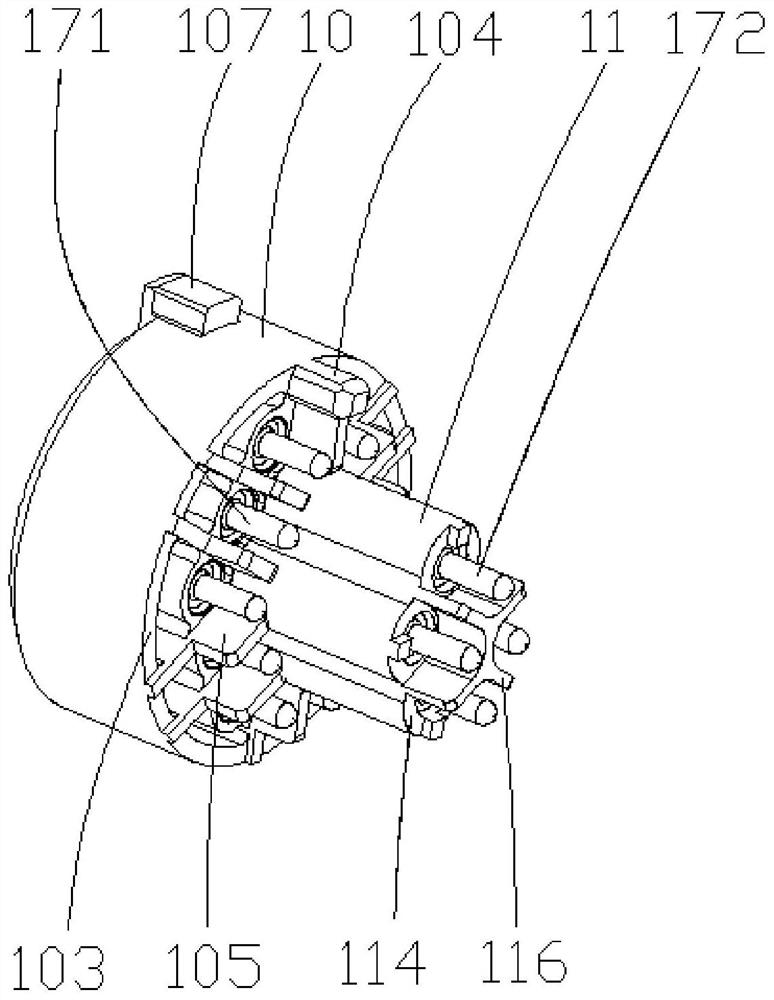

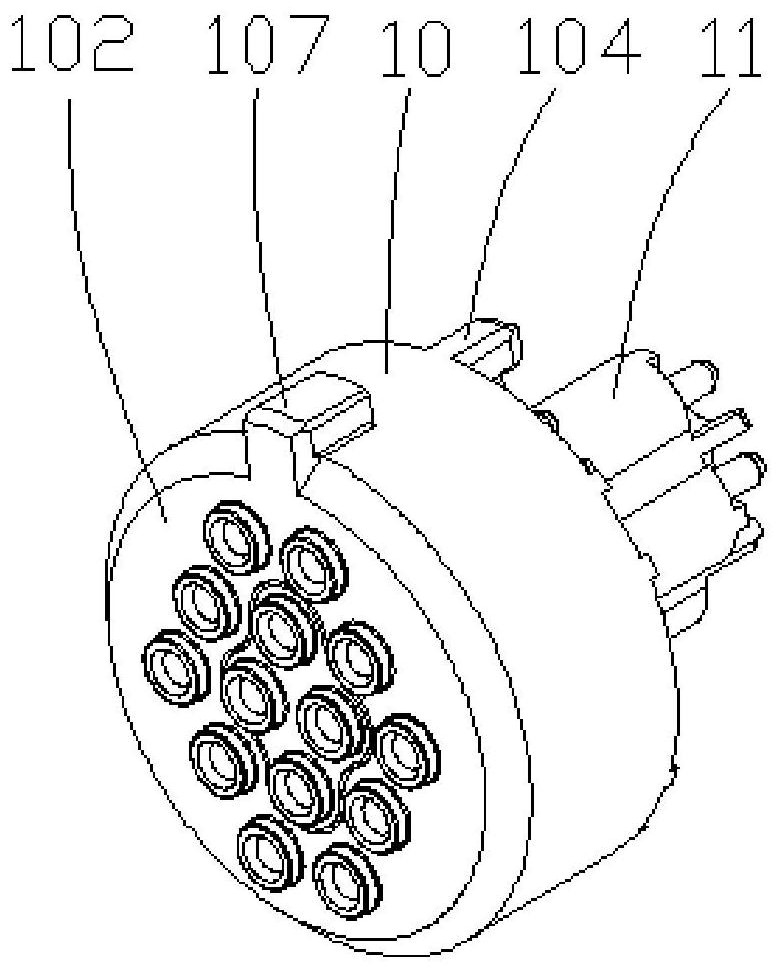

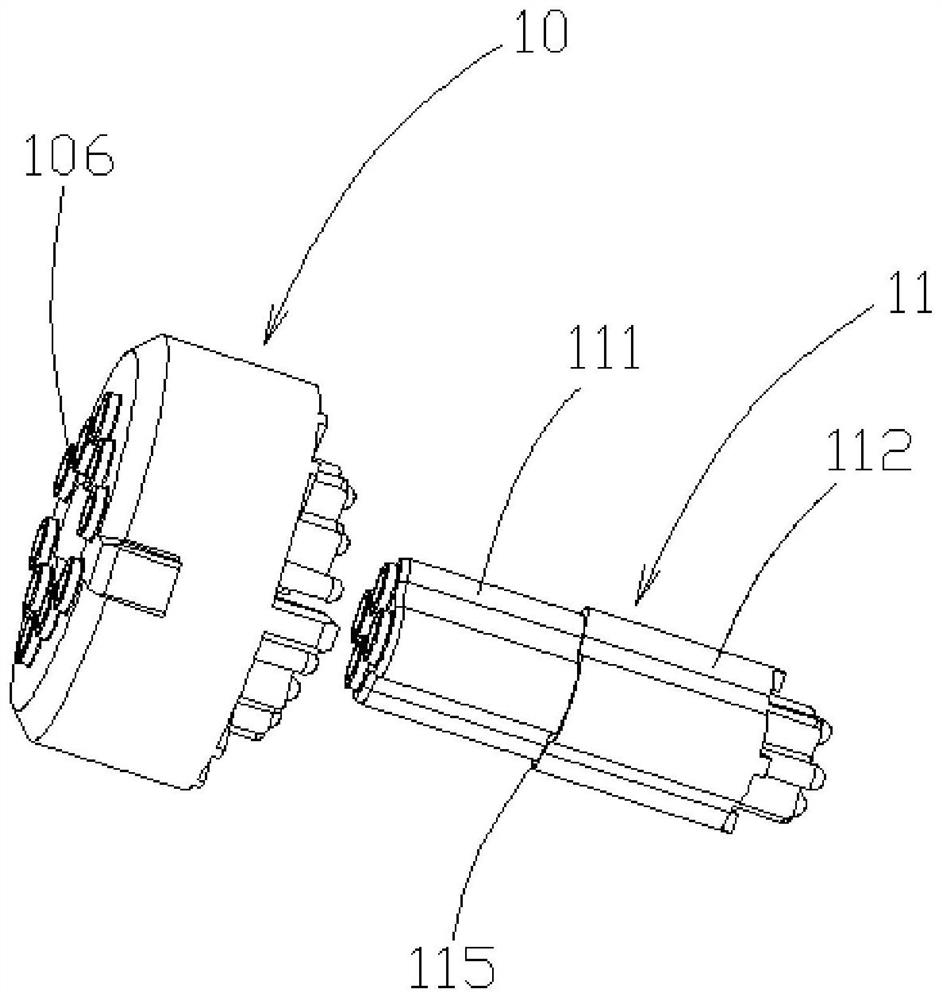

[0039] Such as Figure 1-Figure 10 As shown, a transition structure provided in this embodiment includes a main connector 10, a sub-connector 11, a first receptacle contact 171 and a second receptacle contact 172, and the main connector 10 is provided with a through The socket hole 100 and the first mounting hole 101, the first socket contact 171 is installed in the first mounting hole 101, the sub-connector 11 is provided with a through second mounting hole 110, and the second socket contact 172 is installed In the second mounting hole 110 , the first end of the sub-connector 11 is fitted into the insertion hole 100 for fitting, and the second end of the sub-connection 11 extends out of the insertion hole 100 .

[0040] Such as image 3 , Figure 5 and Figure 6 As shown, the sub-connector 11 includes an insertion portion 111 close to the main connector 10 and an installation porti...

Embodiment 2

[0050] Embodiment 2: Embodiment 2 is a specific implementation of the connector.

[0051] Such as Figure 7 , 11 - Figure 14 As shown, a connector provided in this embodiment includes a socket 14, an insulator 15, an adapter pin 16 and the adapter structure in Embodiment 1. The socket 14 is provided with a through third mounting hole 141, and the insulator 15 is set In the third installation hole 141, the adapter pins 16 are arranged on the insulator 15, the number of the adapter pins 16 is consistent with the sum of the first jack contacts 171 and the second jack contacts 172 and Corresponds to conductive contacts.

[0052] In this embodiment, both ends of the adapter pin 16 are pin-type, one end is mated with the socket, and the other end is mated with the adapter structure.

[0053] Such as Figure 11-Figure 14 As shown, the first end of the main connector 10 is provided with a hollow first protrusion 106 at the outer edge corresponding to the first installation hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com