Perfusion system and perfusion forming process for pre-buried wind power blade root

A wind power blade and pre-embedded technology is applied in the field of composite material molding, which can solve the problems of not simple and fast flow channel operation, poor control of tube opening timing, and high risk of perfusion air leakage, so as to reduce the risk of perfusion air leakage and reduce costs. , Improve the effect of perfusion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

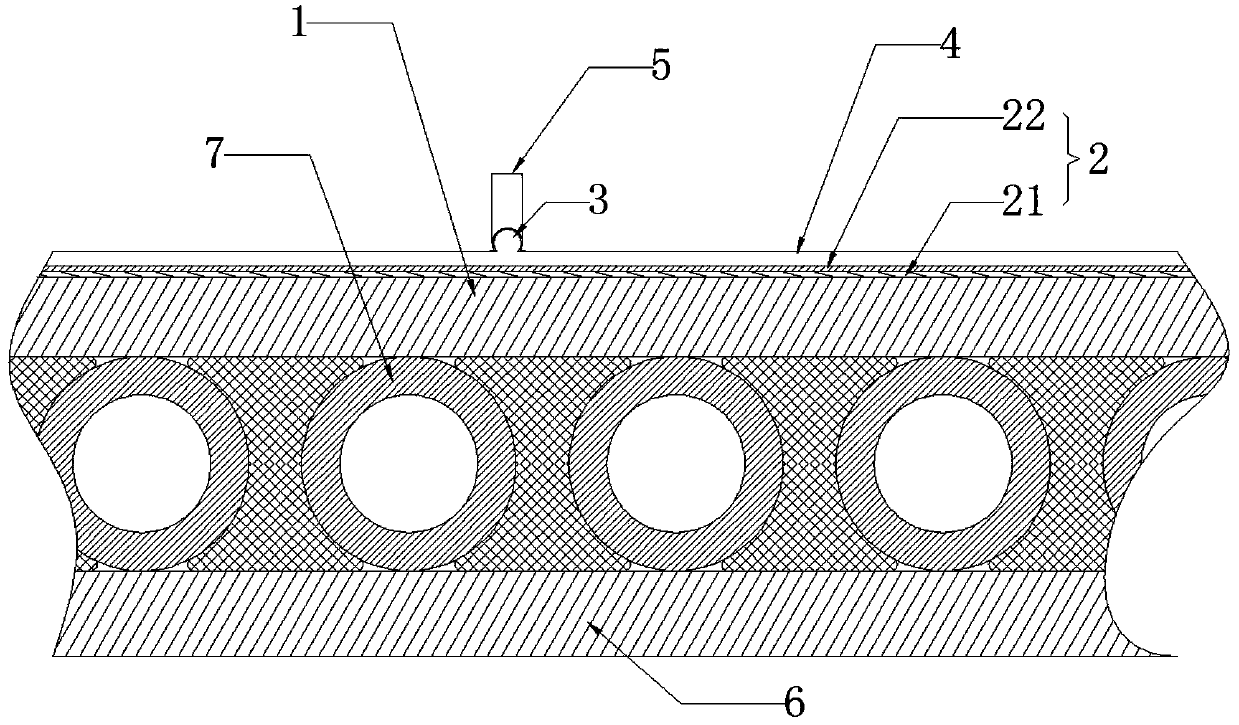

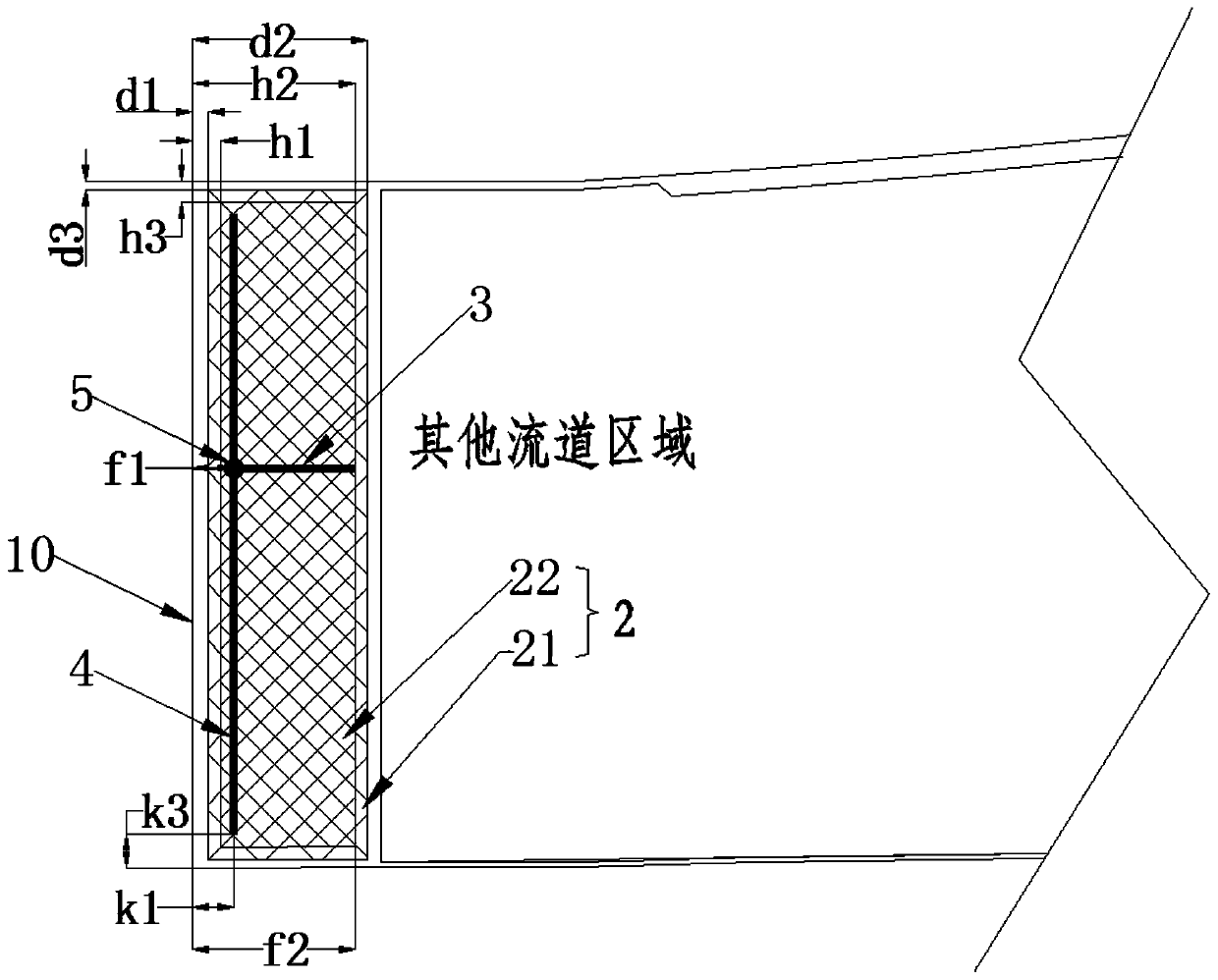

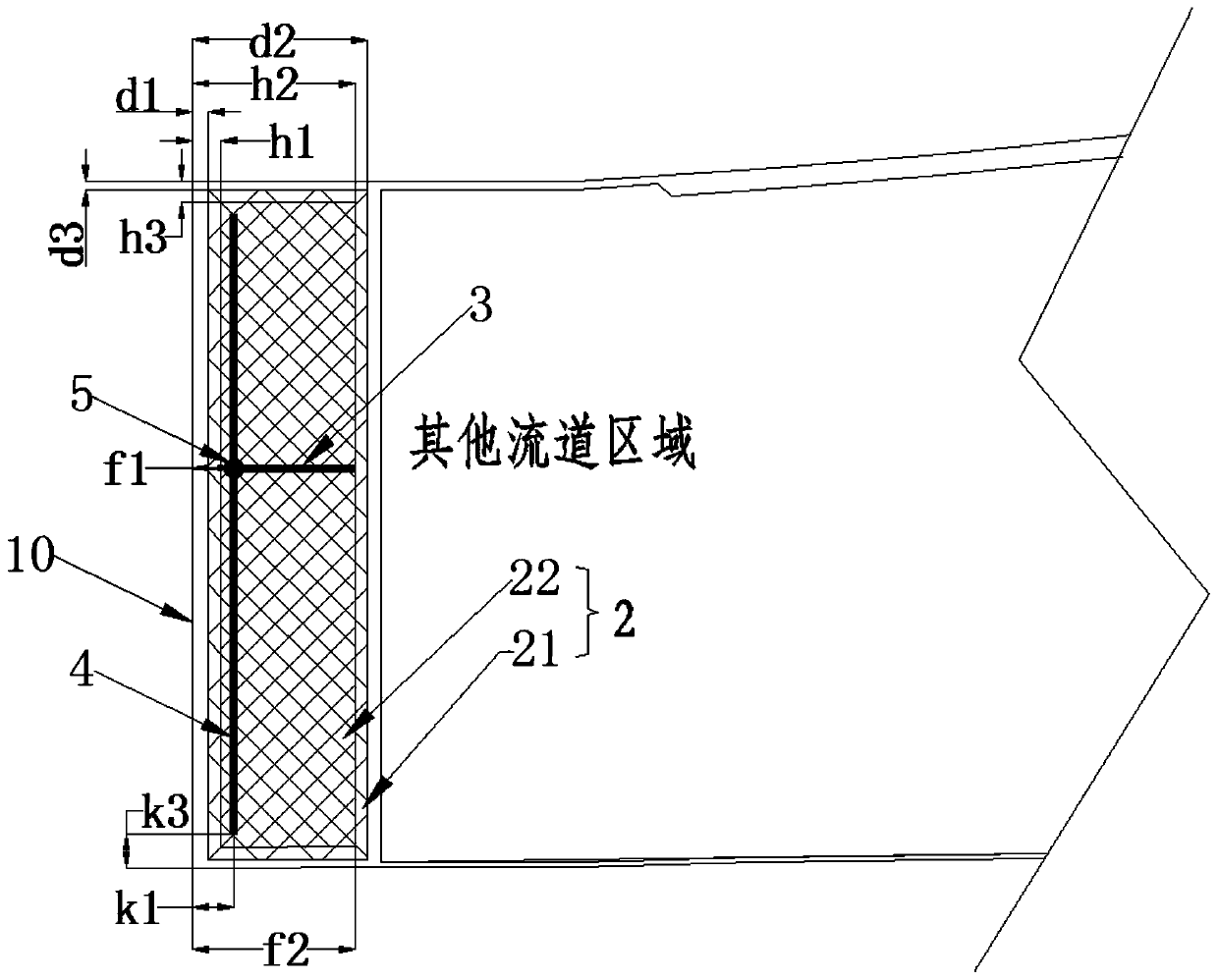

[0036] like figure 1 , figure 2 As shown, a perfusion system for pre-embedded wind turbine blade roots, including a release cloth laid on the glass fiber cloth 1 on the inner surface of the blade root shell, a porous isolation film laid on the surface of the release cloth, with holes The surface of the isolation membrane is laid with a slow-speed diversion net 21, and the surface of the slow-speed diversion net 21 is laid with a fast diversion net 22. Ohm tube 3 and chord injection ohm tube 4 (pre-bent type), and the intersection of spanwise injection ohm tube 3 and chord injection ohm tube 4 is provided with a unique injection port 5, spanwise injection ohm tube 3 and chord An anti-indentation plate is laid under the glue injection ohmic tube 4, and the spanwise glue injection ohmic tube 3 and the chord glue injection ohmic tube 4 are covered with 2 layers of vacuum bag film (used to form a vacuum system with other auxiliary equipment).

[0037] This embodiment also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com