Hand relieving mechanism of parking braking cylinder

A first-hand technology for parking brakes, applied to the operating mechanism of railway vehicle brakes, railway braking systems, railway car body parts, etc. Small workload, easy disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

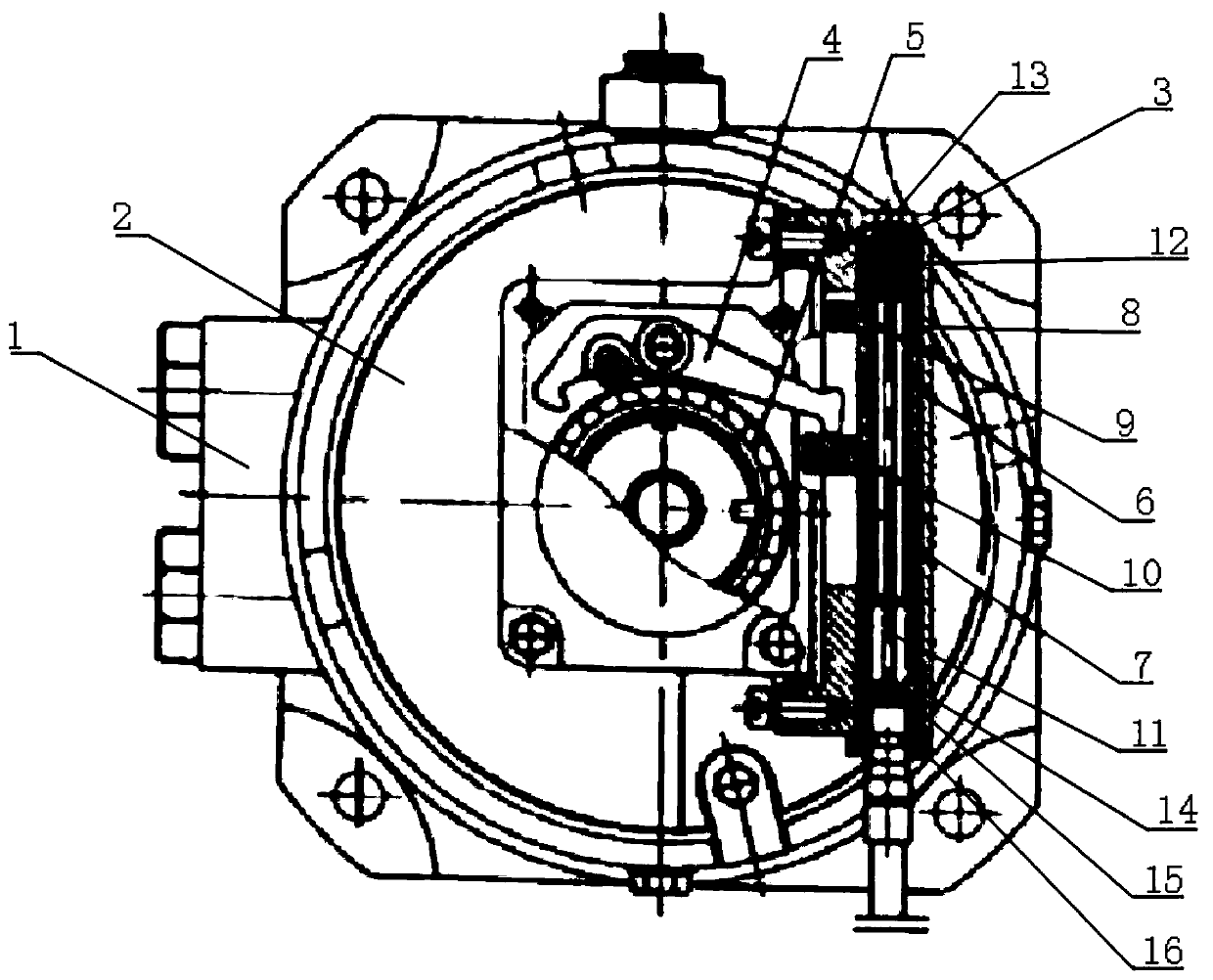

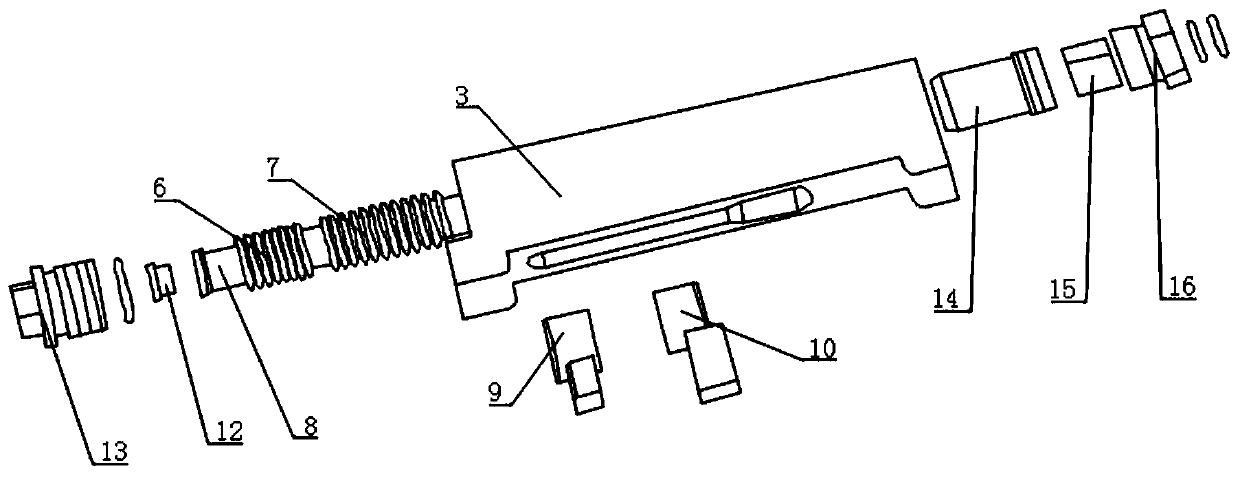

[0030] Such as figure 1 with figure 2 As shown, a hand relief mechanism for a parking brake cylinder is provided on the cylinder head 2 of the parking brake cylinder 1, and the hand relief mechanism includes a hand relief body 3, a pawl 4, and a ratchet sleeve 5 , the first hand relief spring 6, the second hand relief spring 7, the hand relief sliding sleeve 8, the first pawl toggle sleeve 9 and the second pawl toggle sleeve 10, the ratchet sleeve 5 is rotatably connected to the cylinder On the cover 2, the ratchet 4 is pivotally connected to the cylinder head 2 through the ratchet 4, and one end of the ratchet 4 matches the tooth groove of the ratchet sleeve 5.

[0031] The hand relief body 3 is fixedly connected to the cylinder head 2, the hand relief body 3 is provided with an installation cavity along the length direction, and the side wall of the hand relief body 3 is provided with a sliding groove, and the sliding groove is connected to the The installation cavity is ...

Embodiment 2

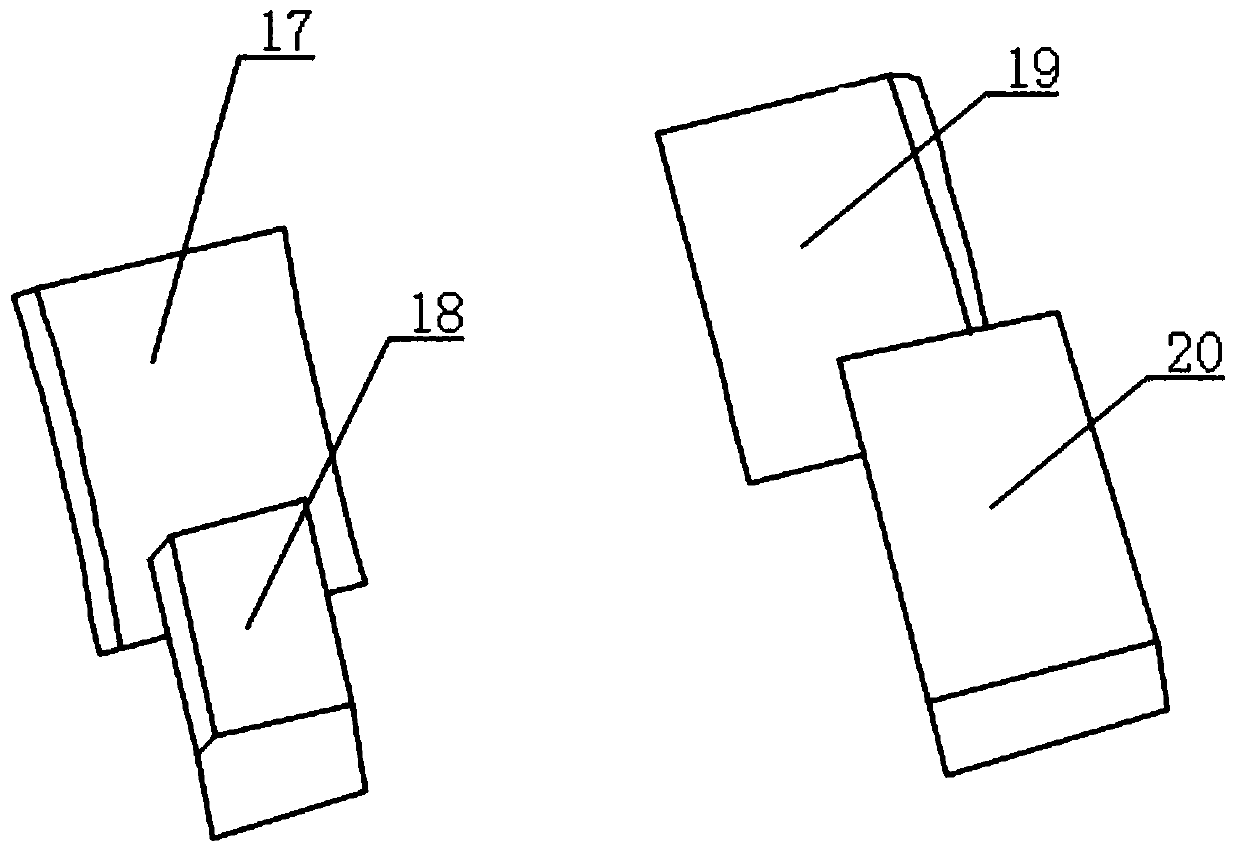

[0042] Such as figure 1 with image 3 As shown, this embodiment is based on Embodiment 1, the first ratchet shifting sleeve 9 includes a first connecting sleeve 17 and a first shifting block 18, and the first shifting block 18 is connected to the first shifting block 18. A connecting sleeve 17 is fixedly connected, and the first connecting sleeve 17 is fixedly sleeved outside the hand relief sliding sleeve 8, and the first toggle block 18 protrudes from the sliding groove and is slidably connected with the sliding groove ; The second ratchet shifting sleeve 10 includes a second connecting sleeve 19 and a second shifting block 20, the second shifting block 20 is fixedly connected with the second connecting sleeve 19, and the second connecting sleeve 19 is fixedly sleeved on the outside of the hand relief sliding sleeve 8, and the second toggle block 20 protrudes from the sliding groove and is slidably connected with the sliding groove.

[0043] The second shifting block 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com