Bagged and box-packed food packing device

A food and boxed technology is applied in the field of packaging devices for bagged and boxed foods, which can solve the problems of complex structure, time-consuming and laborious production efficiency, poor applicability, etc. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

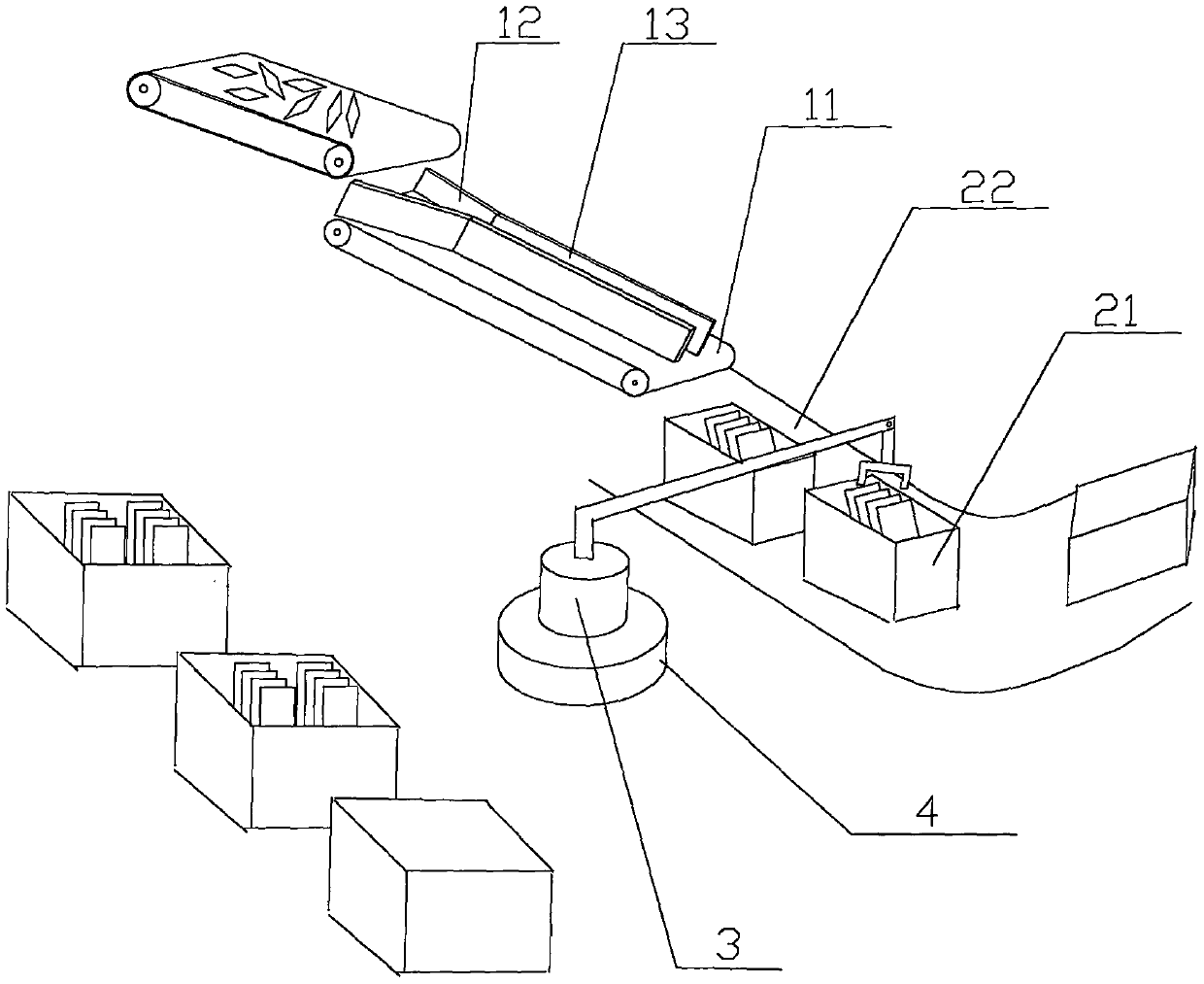

[0035] This embodiment provides a packing device for bagged and boxed food, such as figure 1 As shown, the device includes a sorting mechanism 1, a stacking mechanism 2, a boxing mechanism 3 and a controller 4. The sorting mechanism 1 undertakes the bagged or boxed scattered food and organizes the scattered food, and the stacking mechanism 2 undertakes the sorting Mechanism 1 has sorted the food, and puts the sorted food in sequence. The packing mechanism 3 is used to pack the neatly stacked food in the stacking mechanism 2. The sorting mechanism 1, the stacking mechanism 2 and the packing mechanism 3 are all connected with the control The controller 4 is electrically connected, and the whole packing process is controlled by the controller 4.

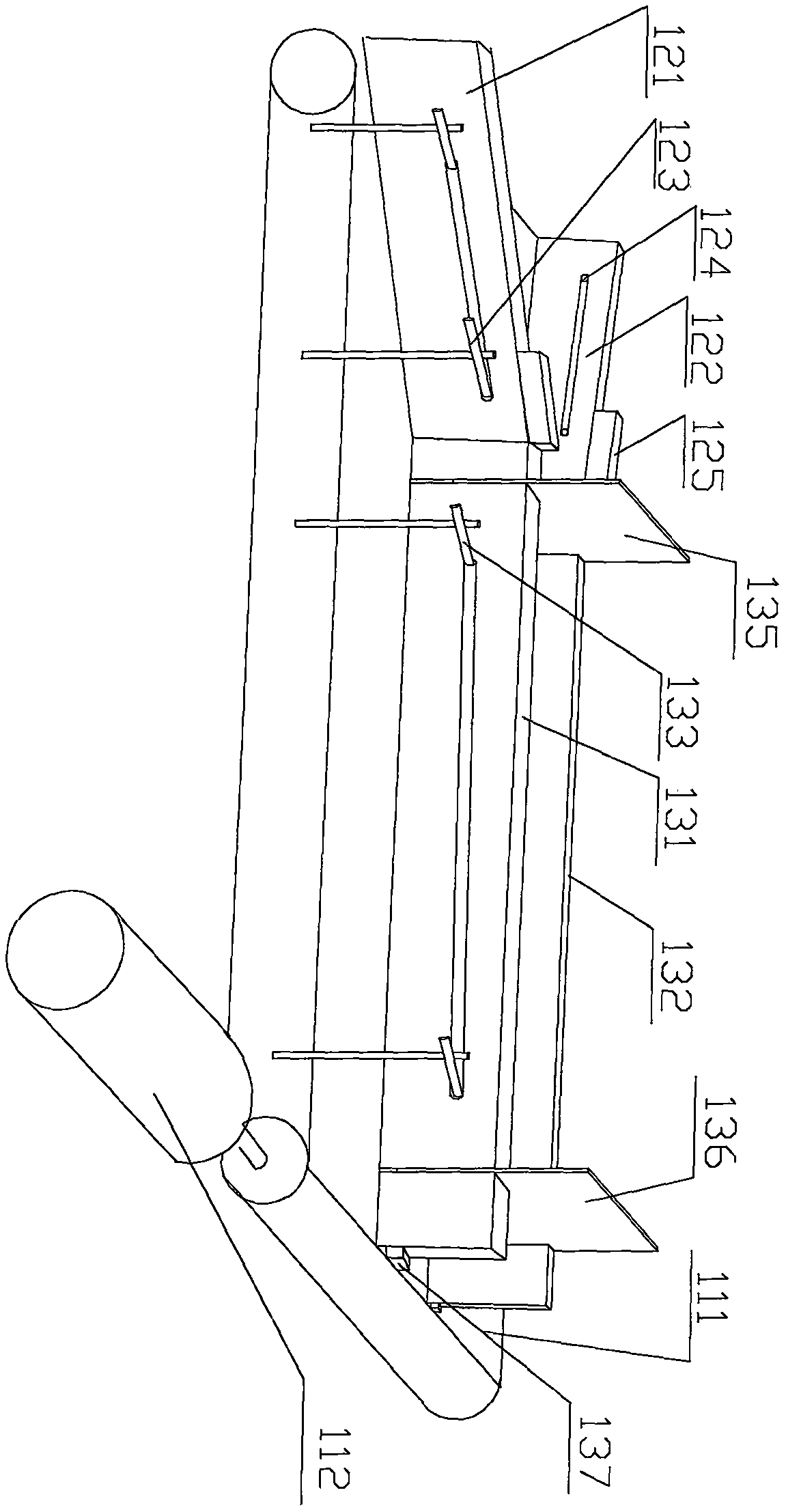

[0036] Specifically, such as figure 2As shown, the sorting mechanism 1 includes a first conveying structure 11, a first baffle plate 12 and a second baffle plate 13, the feeding end of the first conveying structure 11 accepts the bagg...

Embodiment 2

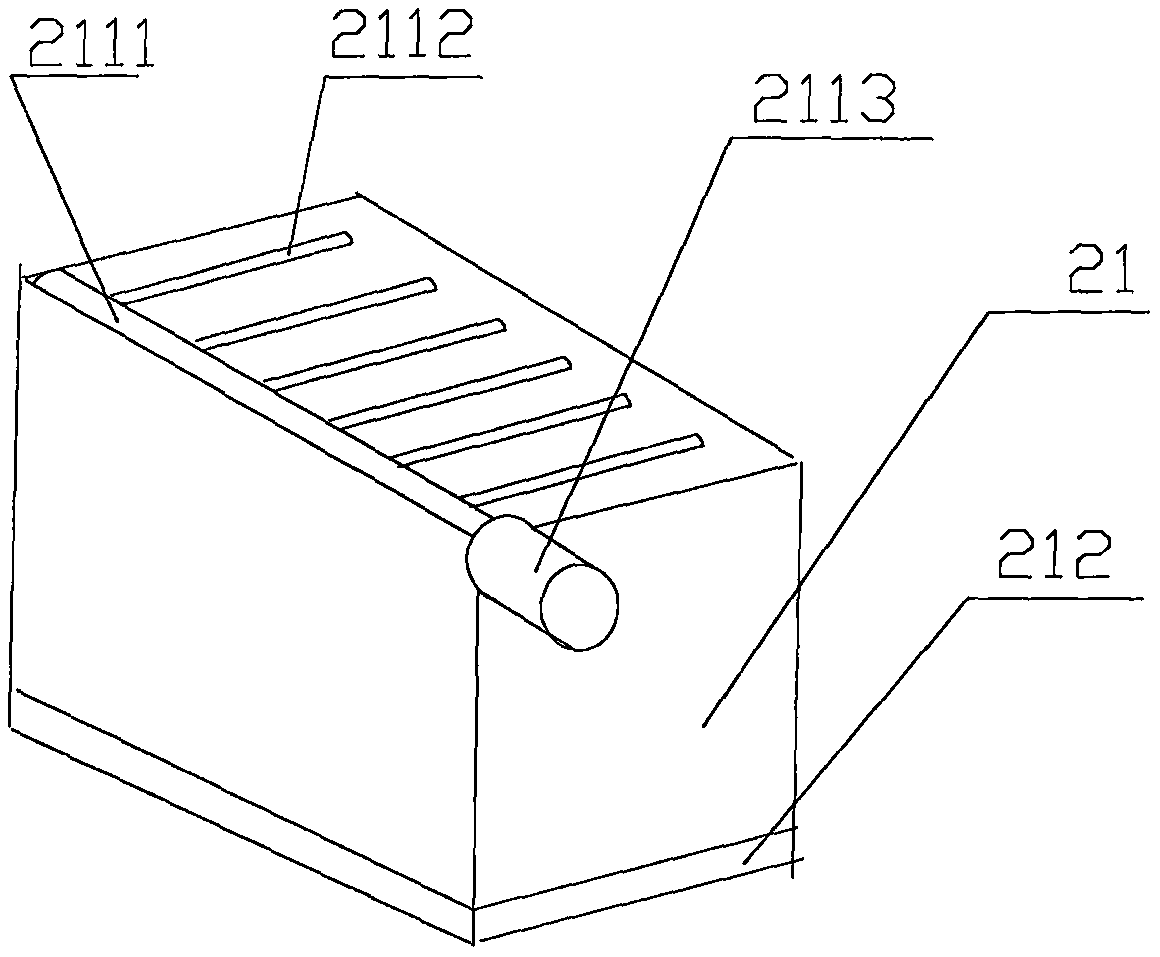

[0043] Further, in order to expand the applicability of the device, such as Figure 4 As shown, the limit rod 2112 can be slidably arranged in the axial direction of the fixed shaft 2111, and one end of the limit rod 2112 can be axially slidably sleeved on the fixed shaft 2111, and each two limit rods 2112 can be adjusted according to the thickness of the food. The distance makes a set of devices suitable for stacking and packing different types of food. Except that the limit mechanism 211 is different from that of embodiment 1, other structures in this embodiment are the same as those of embodiment 1.

[0044] A packing device for bagged or boxed food provided by the present invention, when in use, first adjust the distance between the first baffle plate 12 and the second baffle plate 13 according to the width of the bagged or boxed food , according to the thickness of the bagged or boxed food, adjust the distance between the first baffle plate 12, the second baffle plate 13,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap