A kind of on-line cutting and rejecting method for strip material

A strip and cutting technology, applied in the direction of folding thin materials, thin material processing, metal processing, etc., can solve the problems of low work efficiency, high labor costs, and long-term monitoring by operators, so as to improve production efficiency and improve safety. sex, reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

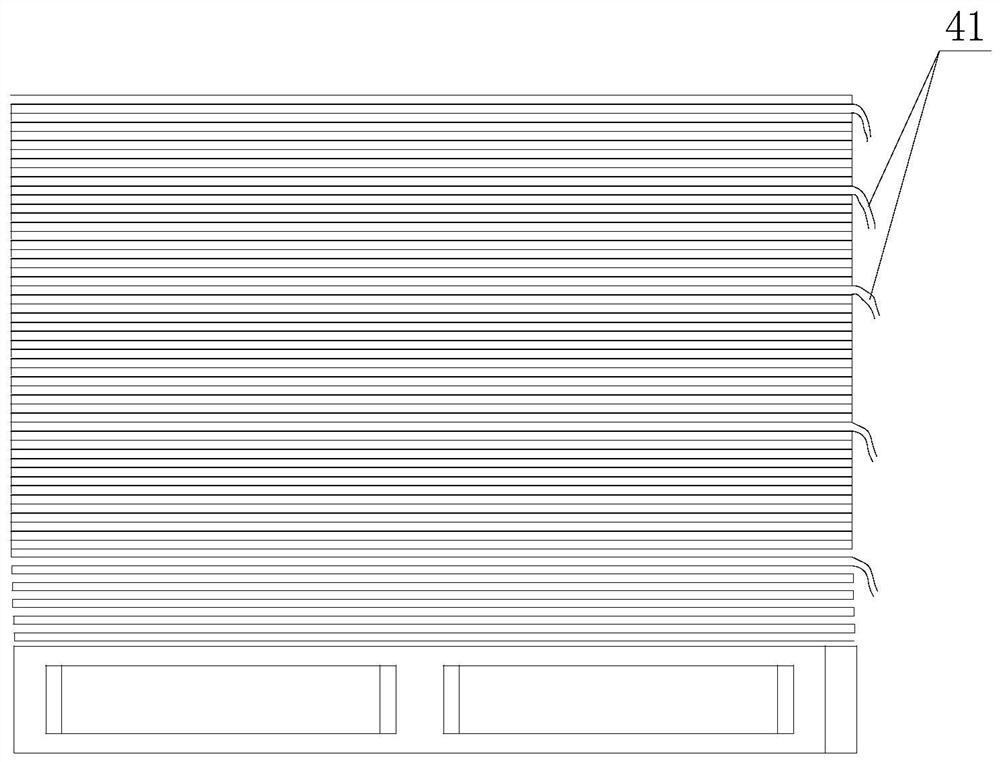

[0045] This embodiment is an online cutting and rejecting method for strips, which is applied to box-type rewinding equipment, that is, the material storage device in this embodiment is a box-type swinging rewinding device.

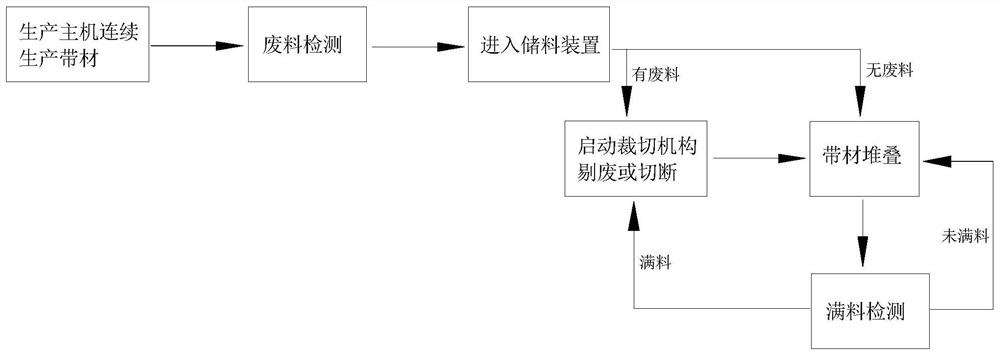

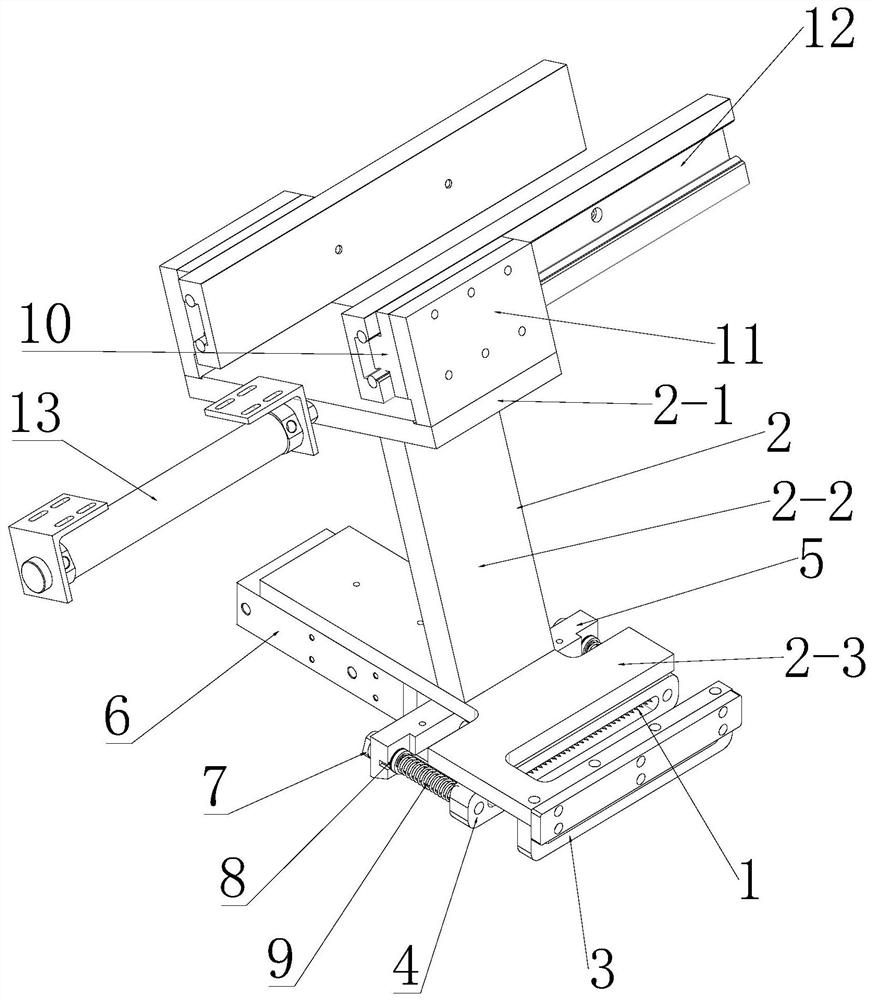

[0046] The method is by setting a movable cutting mechanism b (such as Image 6 shown), the first detection mechanism is set on the production host or the material storage device, and the second detection mechanism is set on the material storage device; figure 1 As shown, the process of online cutting and rejecting specifically includes the following steps:

[0047] (1) The production host continuously produces strips and transports the strips to the storage device, where they are stacked to form a pile;

[0048] During the conveying process or stacking process, the first detection mechanism detects in real time whether there is waste material in the strip, and the second detection mechanism detects in real time whether the strip in the storage device is...

Embodiment 2

[0067] This embodiment is an online cutting and rejecting method for strip materials, which is applied to traditional winding equipment.

[0068] Compared with Embodiment 1, the difference lies in that the structure of the material storage device is different. The material storage device in this embodiment is a traditional roll-type winding device, and the winding roller is used for strip winding. The cutting mechanism is installed on the corresponding frame of the material storage device, and the first detection mechanism and the second detection mechanism are also installed on the corresponding frame of the material storage device. The specific structure of the cutting and rejecting method process and the cutting mechanism realized by it is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com