Computerized embroidery machine thread combing structure

An embroidery machine and thread combing technology, applied in the field of computerized embroidery machine combing thread structure, can solve problems such as failure to comb thread ends or joints in time, joints or thread ends stuck in knitting parts, affecting embroidery quality, etc., so as to improve embroidery weaving quality. , prevent running lines, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

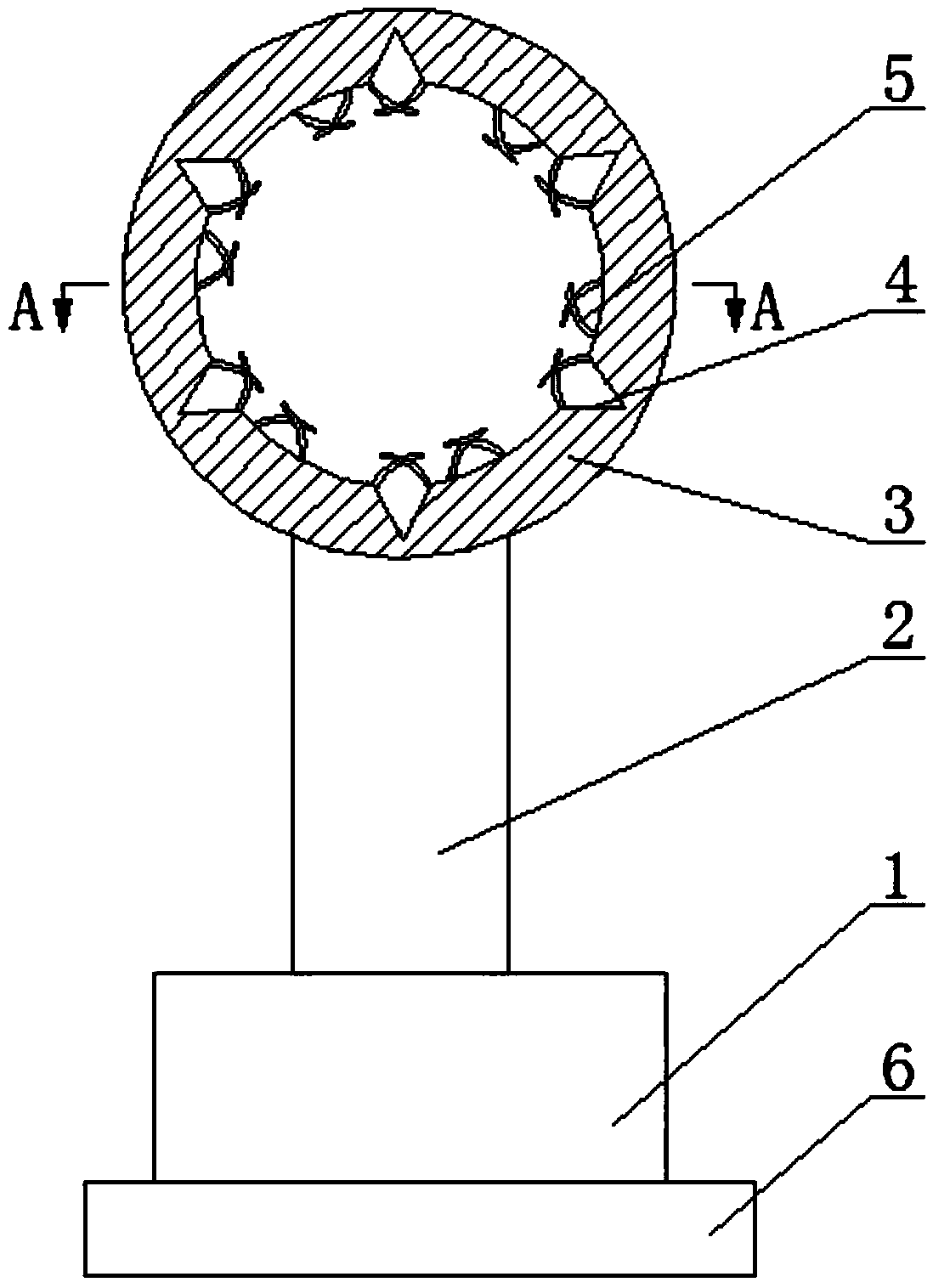

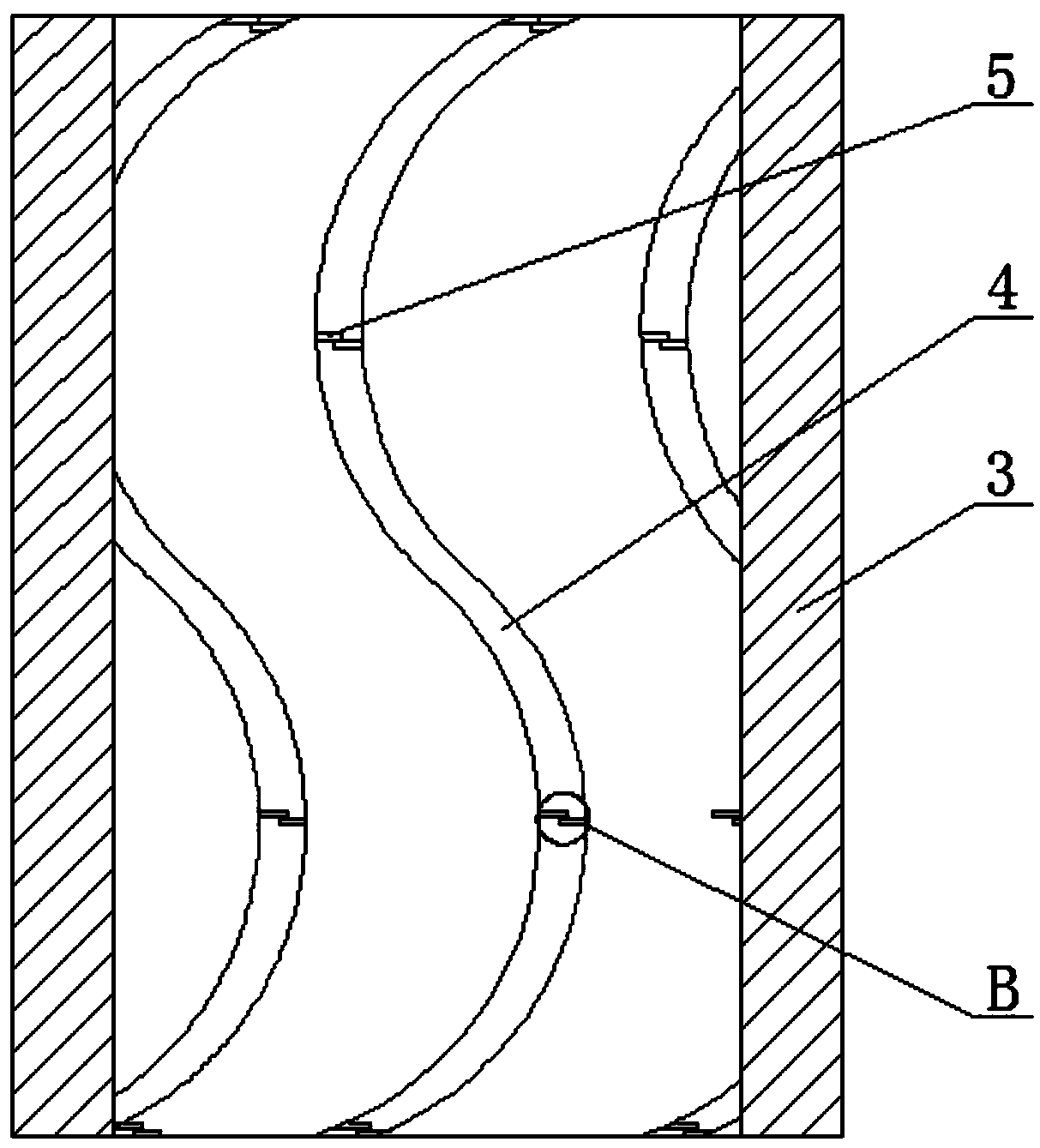

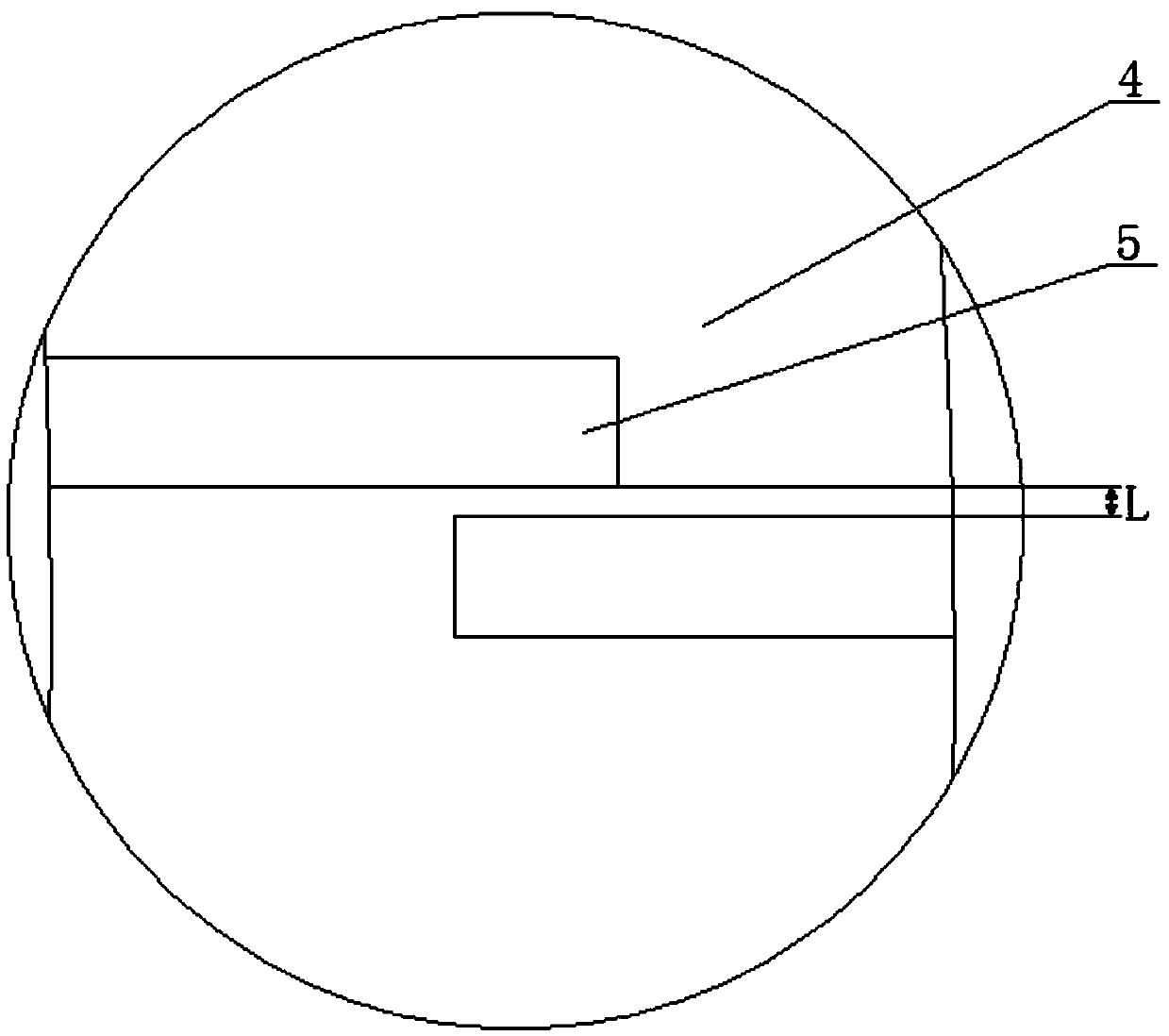

[0012] Such as Figure 1 ~ Figure 3 As shown, a combing structure of a computer embroidery machine includes a base body 1, the upper part of the base body 1 is connected to a cylindrical roller body 3 through a flexible rod 2, the two ends of the cylindrical roller body 3 are open and the interior is hollow, and the inner wall of the cylindrical roller body 3 Grooves 4 are provided in the upper direction, the grooves 4 are S-shaped, the cross-section of the grooves 4 is an inverted triangle, and several pairs of guide bars 5 are arranged on each groove 4, and the two guide bars 5 of each pair are respectively located in the grooves. 4 and arranged alternately on both sides, the gap L between each pair of two guide strips 5 is 0.3-0.5mm, and the lower part of the base 1 is provided with a magnetic piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com