Logic control circuit of slope compensation signal in peak current mode DC-DC converter

A logic control circuit, DC-DC technology, applied in the direction of conversion equipment without intermediate conversion to AC, electrical components, output power conversion devices, etc., can solve problems affecting the transient response characteristics of the system, and achieve ideal control performance. The effect of preventing overcompensation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

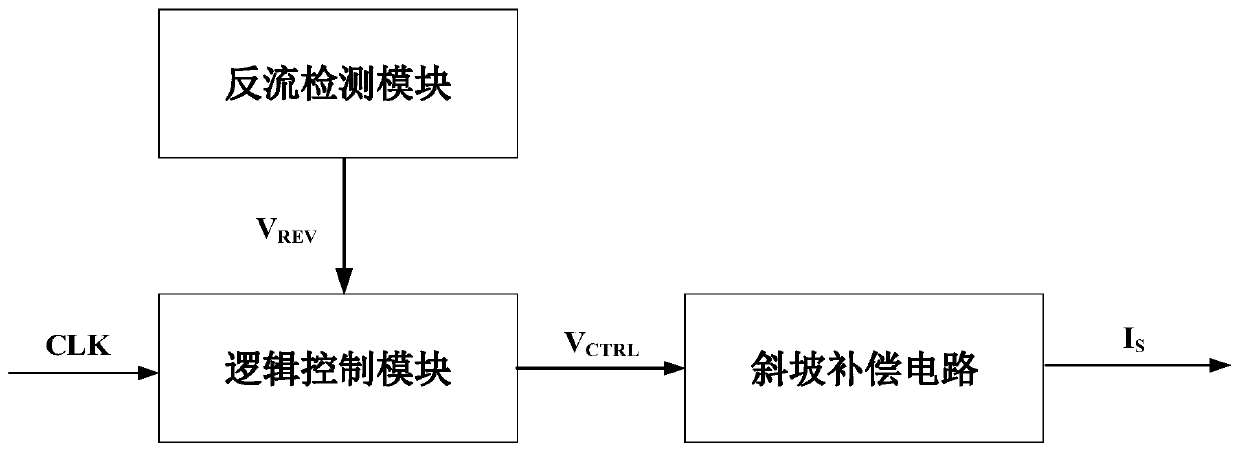

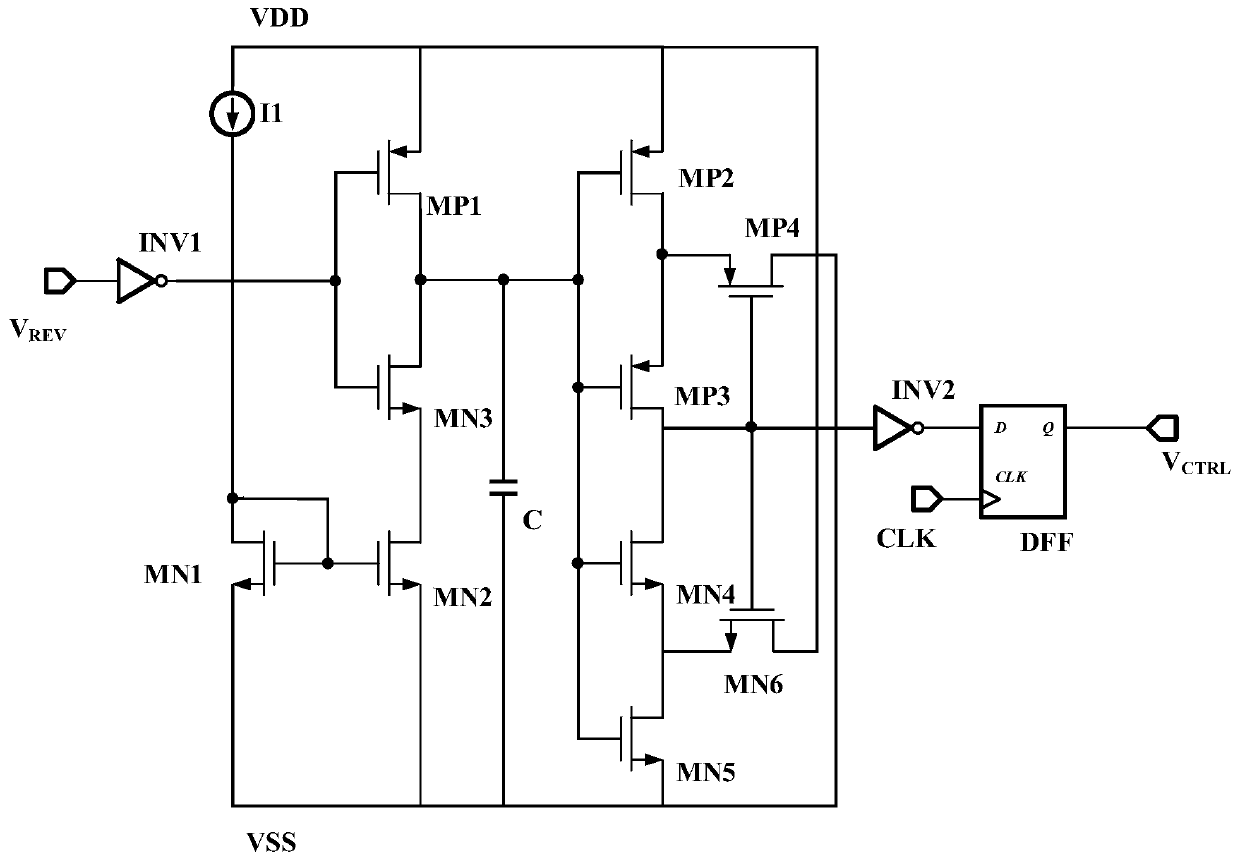

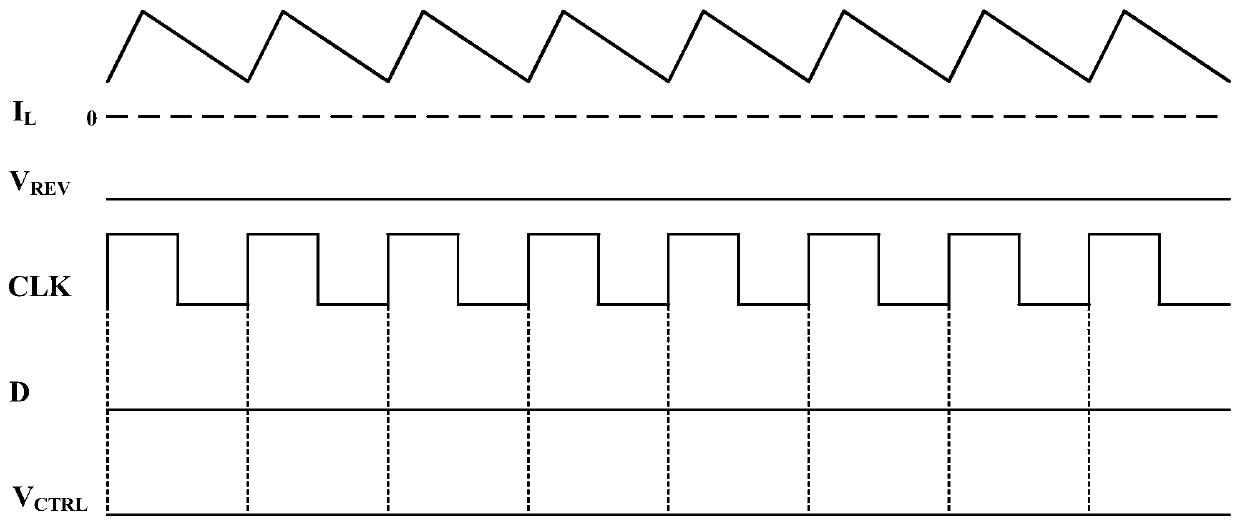

[0021] The present invention proposes a logic control circuit for a slope compensation signal in a peak current mode DC-DC converter, including a reverse current detection module and a logic control module, and the reverse current detection module provides a peak current mode DC-DC conversion circuit for the logic control module. Whether it is in the CCM or DCM working mode information, it is judged whether the peak current mode DC-DC converter is in the CCM or DCM working mode according to detecting whether the peak current mode DC-DC converter has reverse flow. When the peak current mode DC-DC converter does not reverse current, that is, when the peak current mode DC-DC converter is in the CCM working mode, the output of the reverse current detection module is always low; when the peak current mode DC-DC converter When reverse current occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com