High-function heat transfer releases

A release agent and thermal transfer printing technology, which is applied in decorative arts and techniques for producing decorative surface effects, etc. It can solve the impact of thermal transfer label appearance, loose ink adhesion problems, poor ink coverage or wetting problems, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

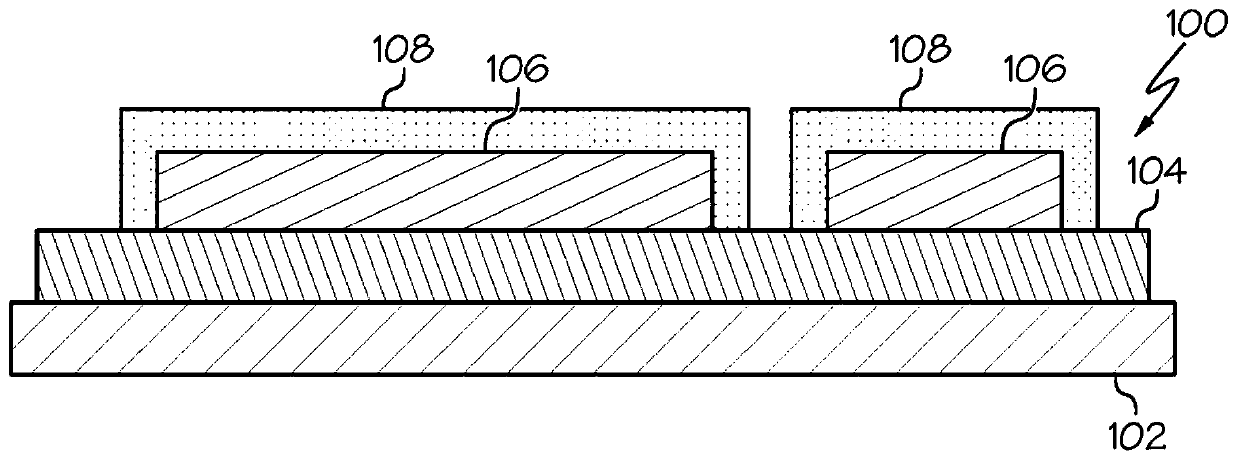

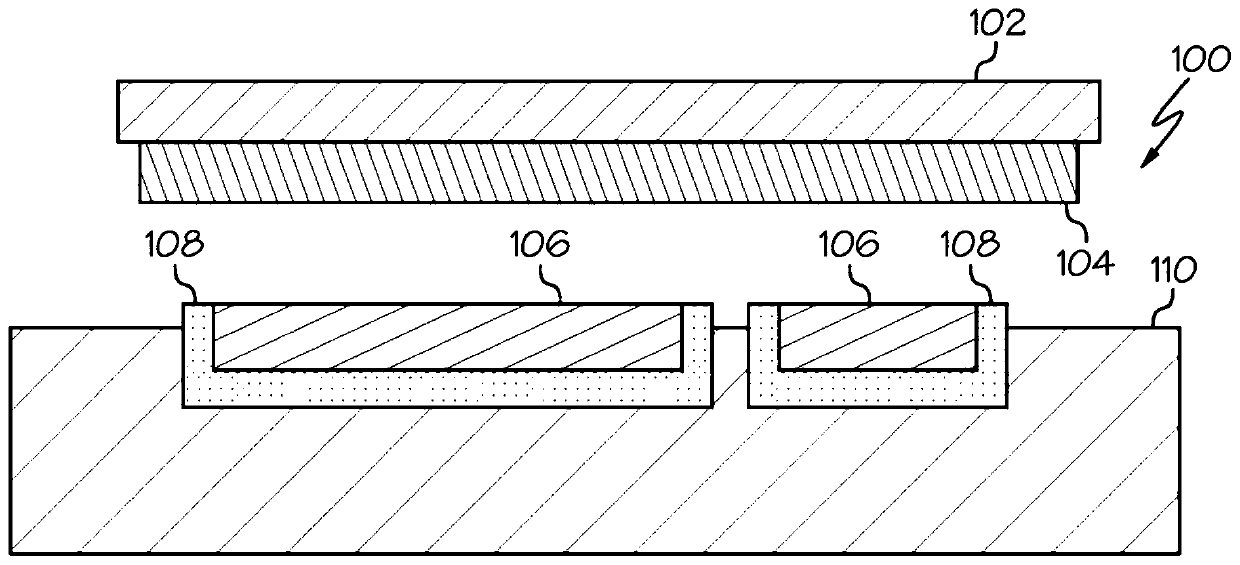

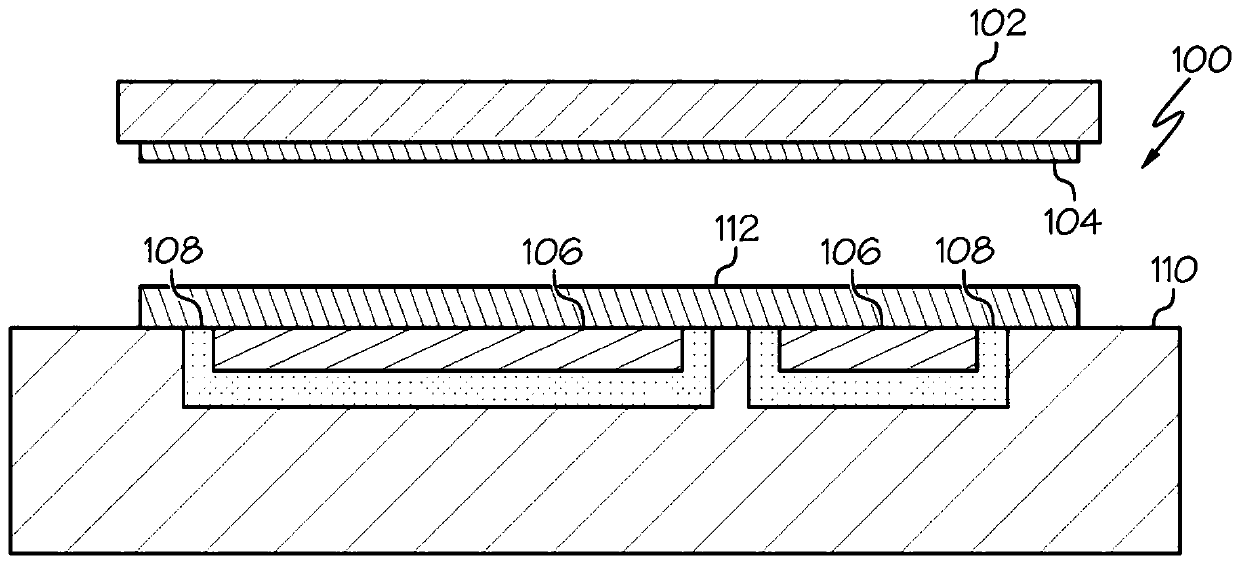

Image

Examples

Embodiment 1

[0044] Gloss Releaser Composition and Application on Support Surface by Screen Printing. An example of a gloss releaser composition of the present invention is:

[0045] gloss releaser (g) CAStat 308 0.54 Joncryl 587 120.12 BLO 170.23 Byk 3560 5.01 XK-635 0.52 Tego Protect 5001 1.31 STI-95 3.05 XR-2500 0.55 Tolonate HDT-90 46

[0046] Here, CAStat 308 is an antistatic agent (by provided), Joncryl-587 is a polyacrylate with -OH and -COOH functional groups (by provided), BLO is a butyrolactone solvent (provided by provided), BYK TM 3560 is a surface modifier with polyether functionality (by provided), XK-635 is a crosslinking catalyst (by King supply), Protect 5001 is another reactive surface modifier (developed by provided), STI-95 is an isocyanate-functional hydrocarbon (provided by supplied), XR-2500 is an aziridine hardener (provided by Avery provided), Tolonate TM HDT-90 is a polyisocy...

Embodiment 2

[0050] Matte release agent composition and application on the carrier surface by screen printing.

[0051]

[0052]

[0053] Here, Ceraflour 920 is an organic powder based matting agent (supplied by Byk), Joncryl TM -550 is a polyacrylate with -OH functional groups. Printing was performed in the same manner as in Example 1. The obtained release agent film has as Figure 5C The layer structure shown.

Embodiment 3

[0055] Gloss + matte combination release for unique "watermark" effects on heat transfer designs. This special gloss + matte combination release is produced by a two-step release agent printing process. First, a gloss release agent was flood printed on PET as in Example 1. Next, design a screen with a patterned structure for the desired "watermark" and then print a matte release agent through the patterned screen (460 mesh or coarser) onto the gloss release agent sheet on a roller screen printing press. The obtained release agent film has as Figure 5D The layer structure shown.

[0056] The gloss + matte release agent printed sheet was then printed on a flatbed screen printer using water based red ink (AQ red), water based white backing (AQ white) and water based adhesive (AG adhesive) . Dryer settings were 120°C with IR on for ink, 85°C with IR off for adhesive, heating time for HT004 tunnel conveyor was about 45s. Cut the printed design patterns (arts) obtained on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com