Detection removing method for defective disposable absorption article

An absorbent article, a disposable technology, applied in absorbent pads, clothing, underwear, etc., can solve the problems affecting the performance of disposable absorbent articles, dripping, etc., to reduce product defect rate, improve quality, and reduce customer complaints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

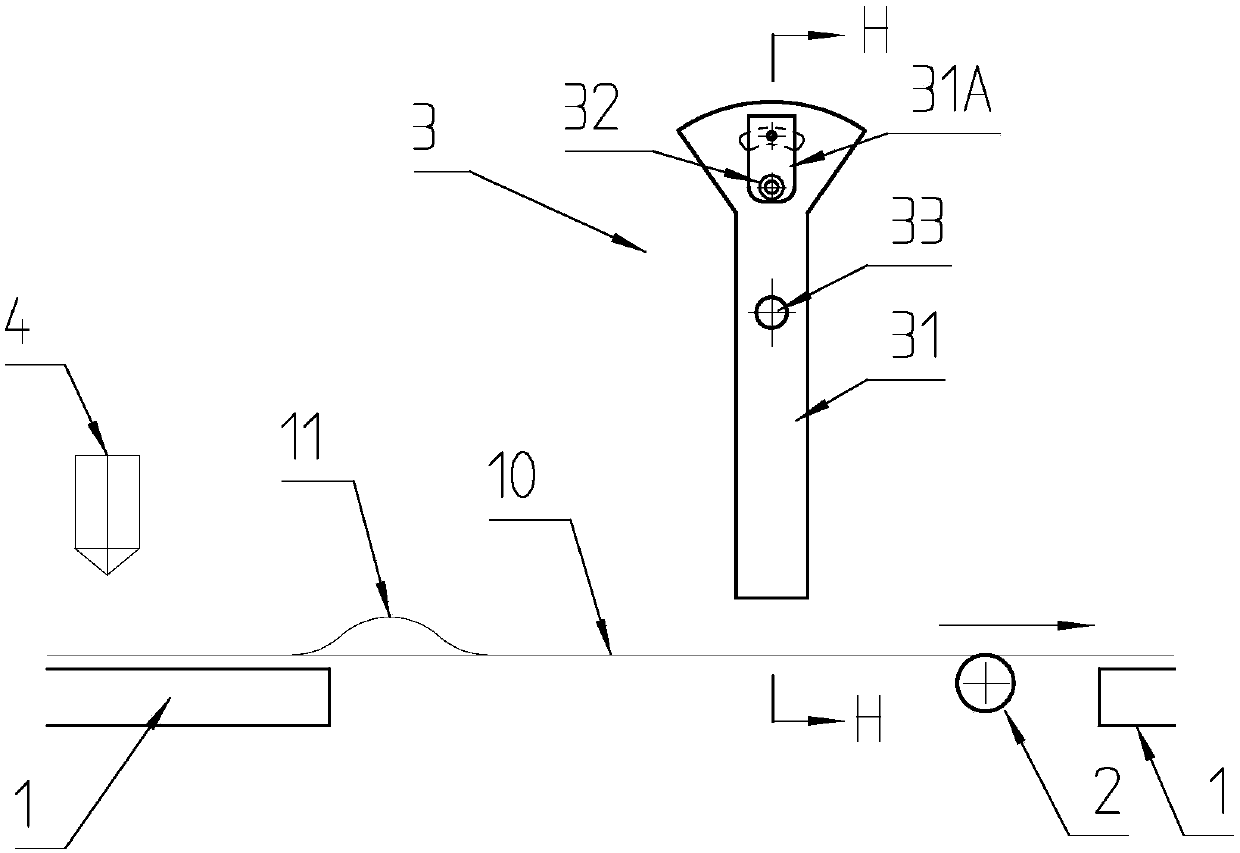

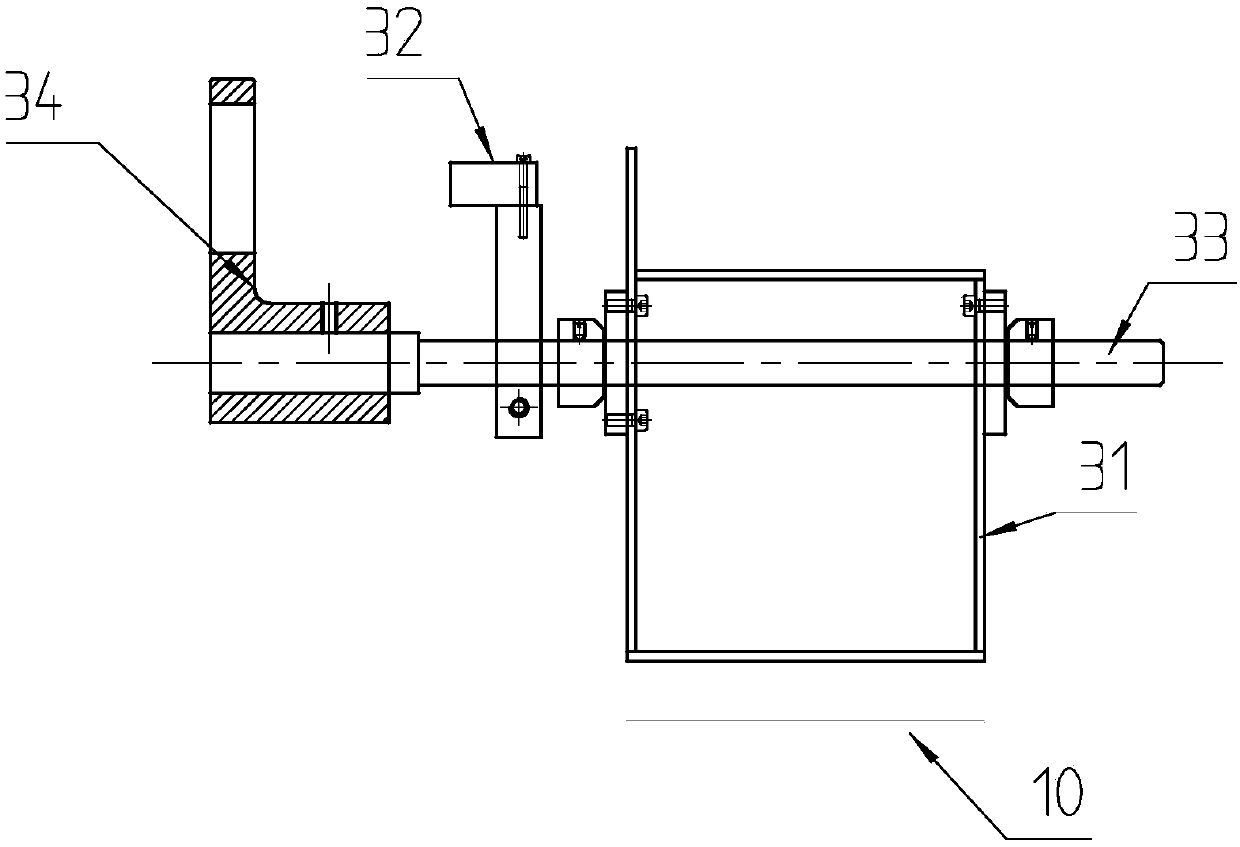

[0020] refer to Figure 1-2 as shown,

[0021] figure 1 Shown is a partial schematic diagram of the production line of disposable absorbent articles in the area where the dispensing glue detection device is located, a method for detecting and rejecting defective disposable absorbent articles, which is used in the production line of disposable absorbent articles, the disposable absorbent The production line of the article combines the liquid-permeable top sheet, the liquid-impermeable back sheet and the absorbent core and other materials into a disposable absorbent article by hot-melt adhesive. As shown in the figure, the continuous material 10 is transported along the support plate 1 in the forward direction of the machine after the glue is sprayed, and a dripping glue detection device 3 is arranged above the continuous material 10 after the glue spraying head 4 of the hot melt glue machine. The dripping glue detection device 3 includes a rotatable passive mechanism and 31 s...

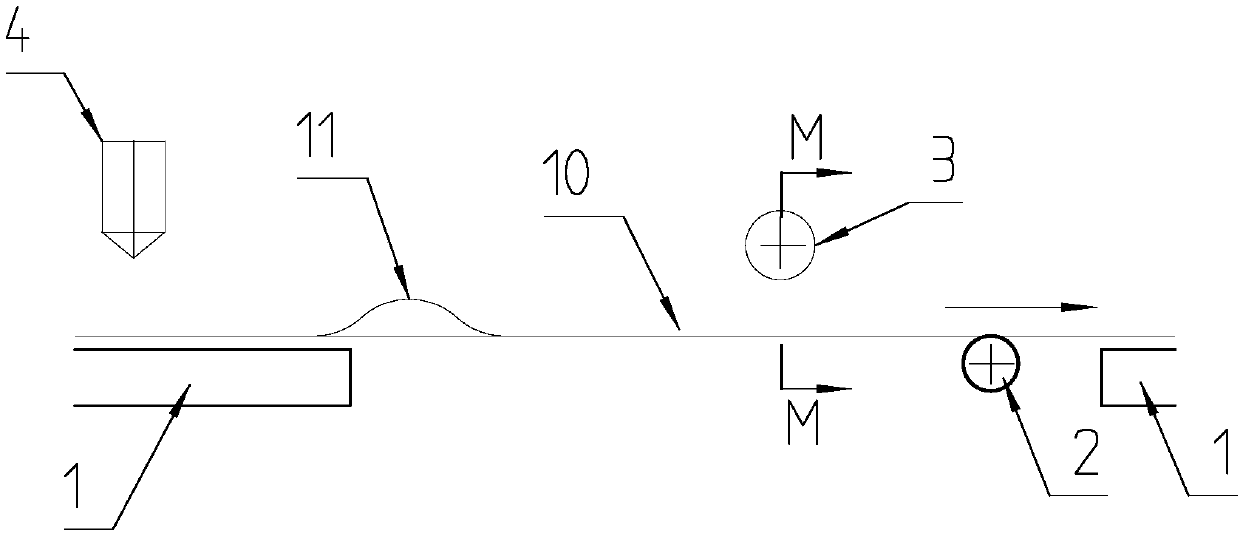

Embodiment 2

[0026] figure 1 Shown is a partial schematic diagram of the production line of disposable absorbent articles in the area where the dispensing glue detection device is located, a method for detecting and rejecting defective disposable absorbent articles, which is used in the production line of disposable absorbent articles, the disposable absorbent The production line of the article combines the liquid-permeable top sheet, the liquid-impermeable back sheet and the absorbent core and other materials into a disposable absorbent article by hot-melt adhesive. As shown in the figure, the continuous material 10 is transported along the support plate 1 in the forward direction of the machine after the glue is sprayed, and a dripping glue detection device 6 is arranged above the continuous material 10 after the glue spraying head 4 of the hot melt glue machine. The glue drop detection device 6 includes a rotatable passive mechanism 61 and a sensor 62, and the distance between the passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com