Production process of prefabricated concrete wallboard containing rough surface

A production process and rough surface technology, which is applied in the production process of concrete wall panels, can solve the problems of factory area or workshop pollution, adverse effects on the integrity of the building structure, excessive concrete waste and difficult to clean up, etc., and achieve the effect of saving time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

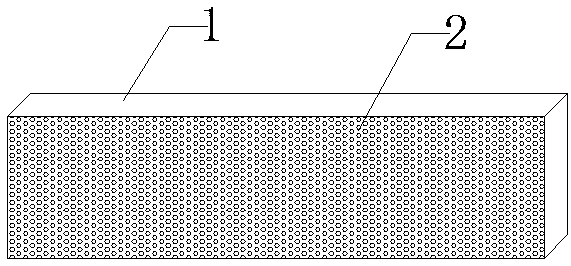

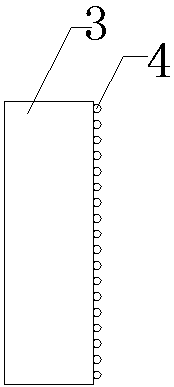

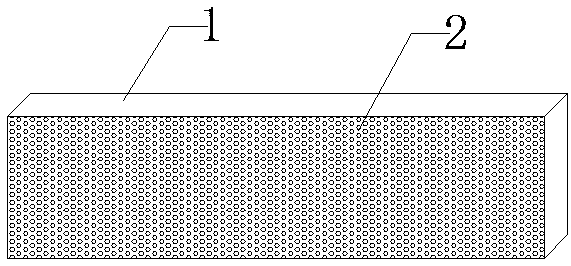

[0027] Such as Figure 1-2 As shown, the production process of prefabricated concrete wall panels with rough surfaces includes the following steps:

[0028] Step 1: Clean the mold table: use the mold table cleaning and polishing machine to clean the mold table for component production, so that the mold table is kept clean and free of concrete laitance, rust spots, water stains, etc.;

[0029] Step 2: Paste double-sided tape: paste double-sided tape on the cleaned mold;

[0030] Step 3: Cutting the bubble film: Cut the bubble film of general size into the size of the bubble film required for making components;

[0031] Step 4: Pave the bubble film: Paste the flat surface of the cut bubble film on the steel mold;

[0032] Step 5: Assemble the mold: Assemble the scattered molds of each part to form a set of molds;

[0033] Step 6: Spray release agent: After the mold is assembled, spray release agent on the mold and table mold surface;

[0034] Step 7: binding steel bars: bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com