Gravity-heat-pipe-combined stand pipe indirect evaporative cooling water chilling unit

A technology of evaporative cooling and gravity heat pipe, which is applied in water shower coolers, indirect heat exchangers, and household heating. Large structural size and other problems, to achieve the effect of diversified operation modes, simple structure, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

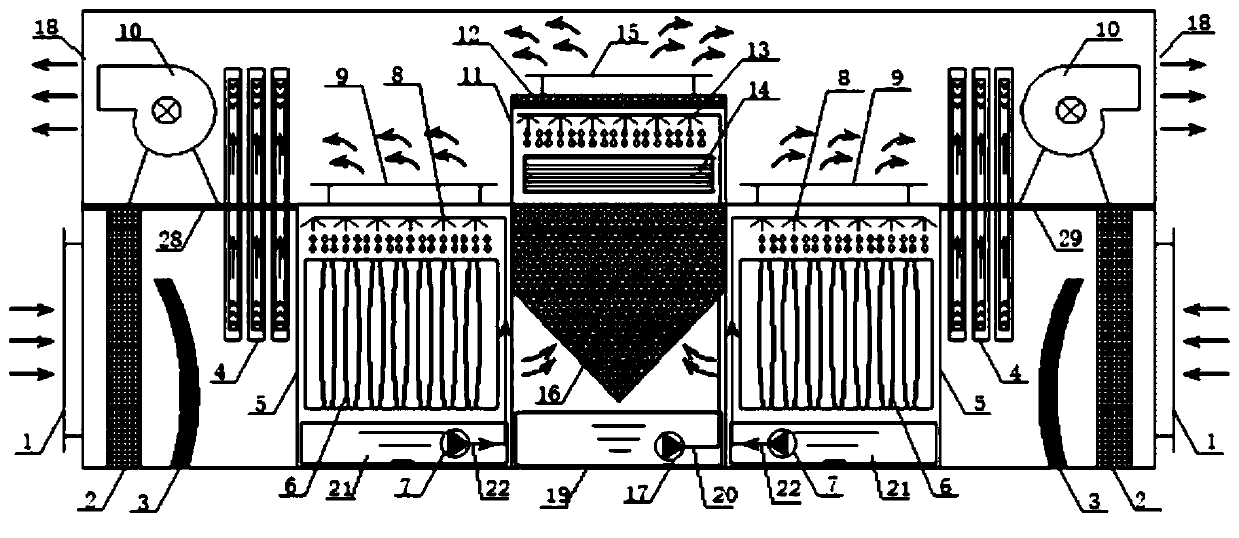

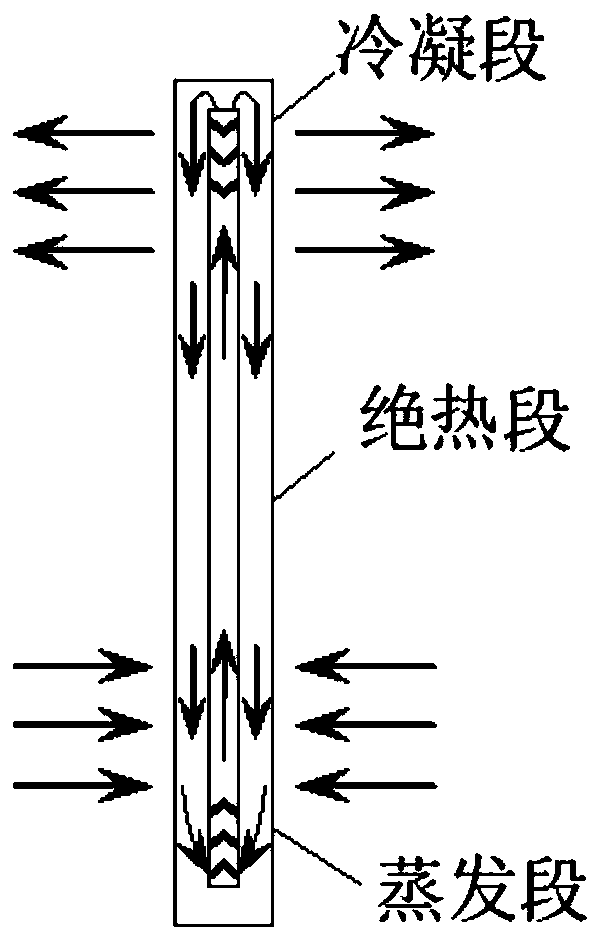

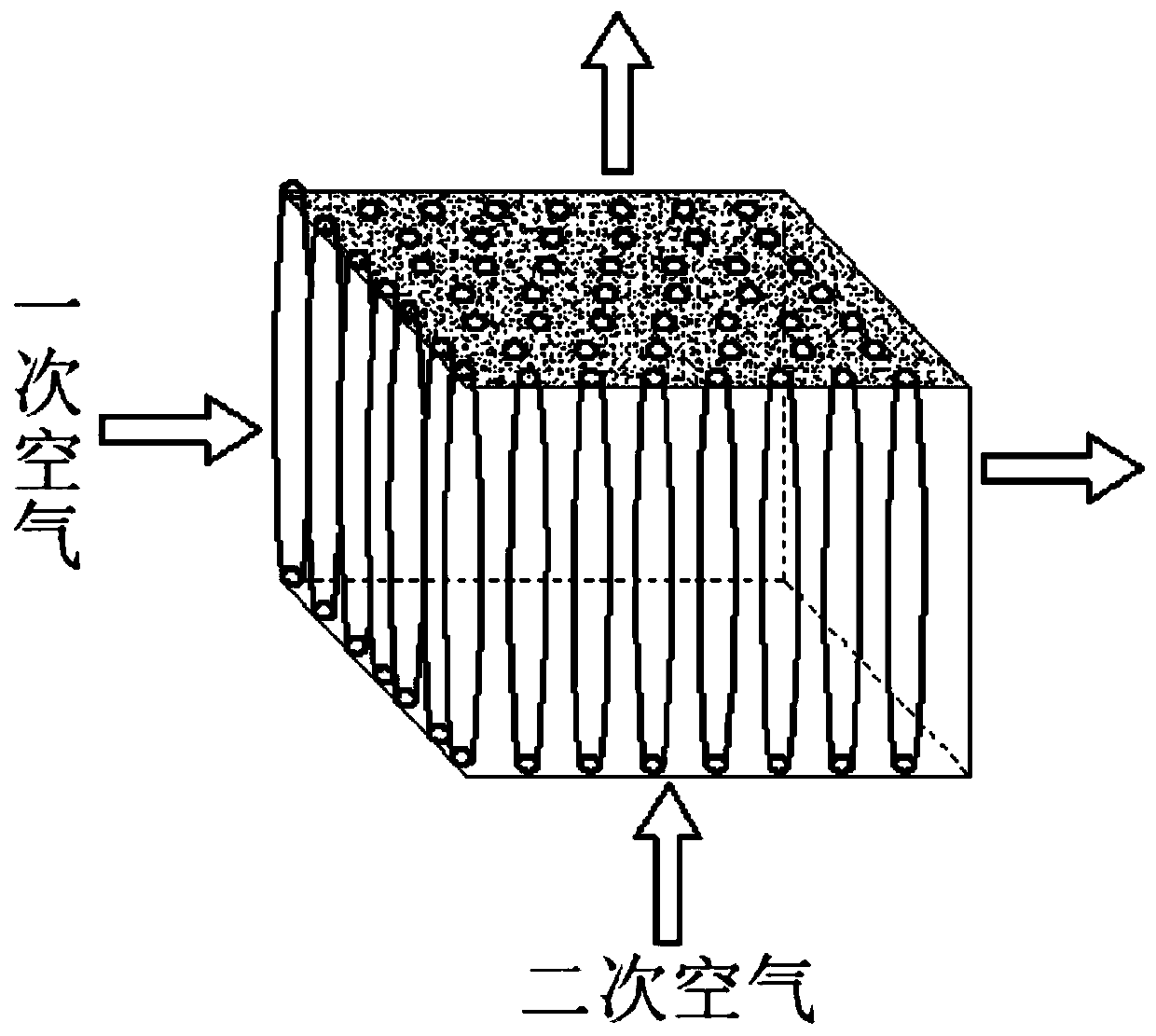

[0025] The present invention is a standpipe indirect evaporative cooling chiller combined with gravity heat pipe, such as Figure 1-2 As shown, including the casing of the organic unit, an upper air passage and a lower air passage distributed up and down are formed in the casing of the unit; the structure of the upper air passage is as follows: air outlets a18 are arranged on the opposite side walls of the unit casing; The structure is as follows: air inlets 1 are arranged on the opposite side walls of the unit shell, and a direct-indirect evaporative cooling unit is arranged in the center of the downflow duct; gravity heat pipes 4 are symmetrically arranged on the left and right sides of the direct-indirect evaporative cooling unit, The evaporation section of the gravity heat pipe 4 is located in the lower air duct, and the condensation sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com