Multi-angle dynamic stiffness experimental device for tire

A technology of dynamic stiffness and test device, applied in the direction of automobile tire test, measurement device, impact test, etc., can solve the problem of lack of strict testing of deformation of dynamic stiffness inner tube and cushion belt assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

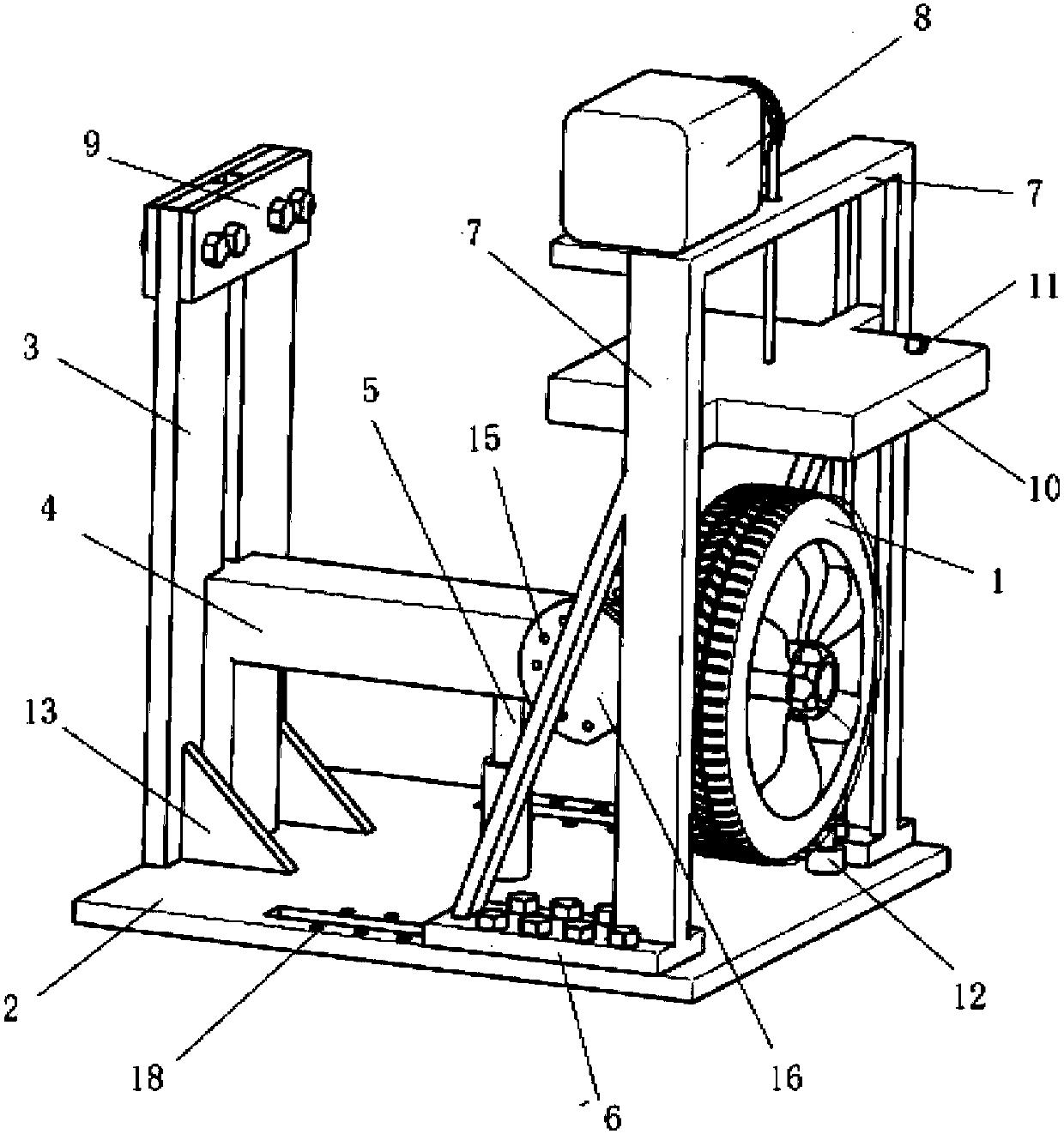

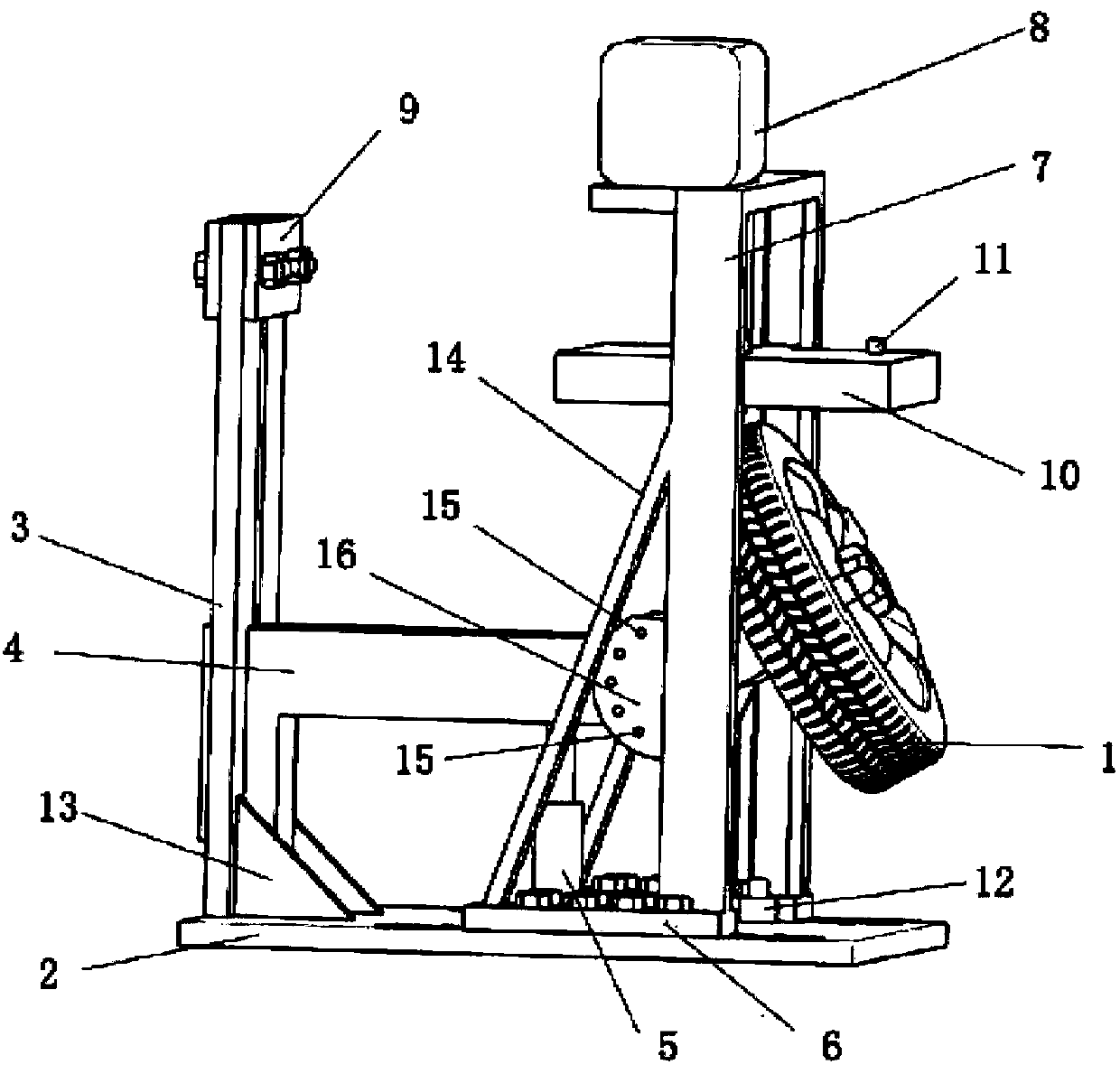

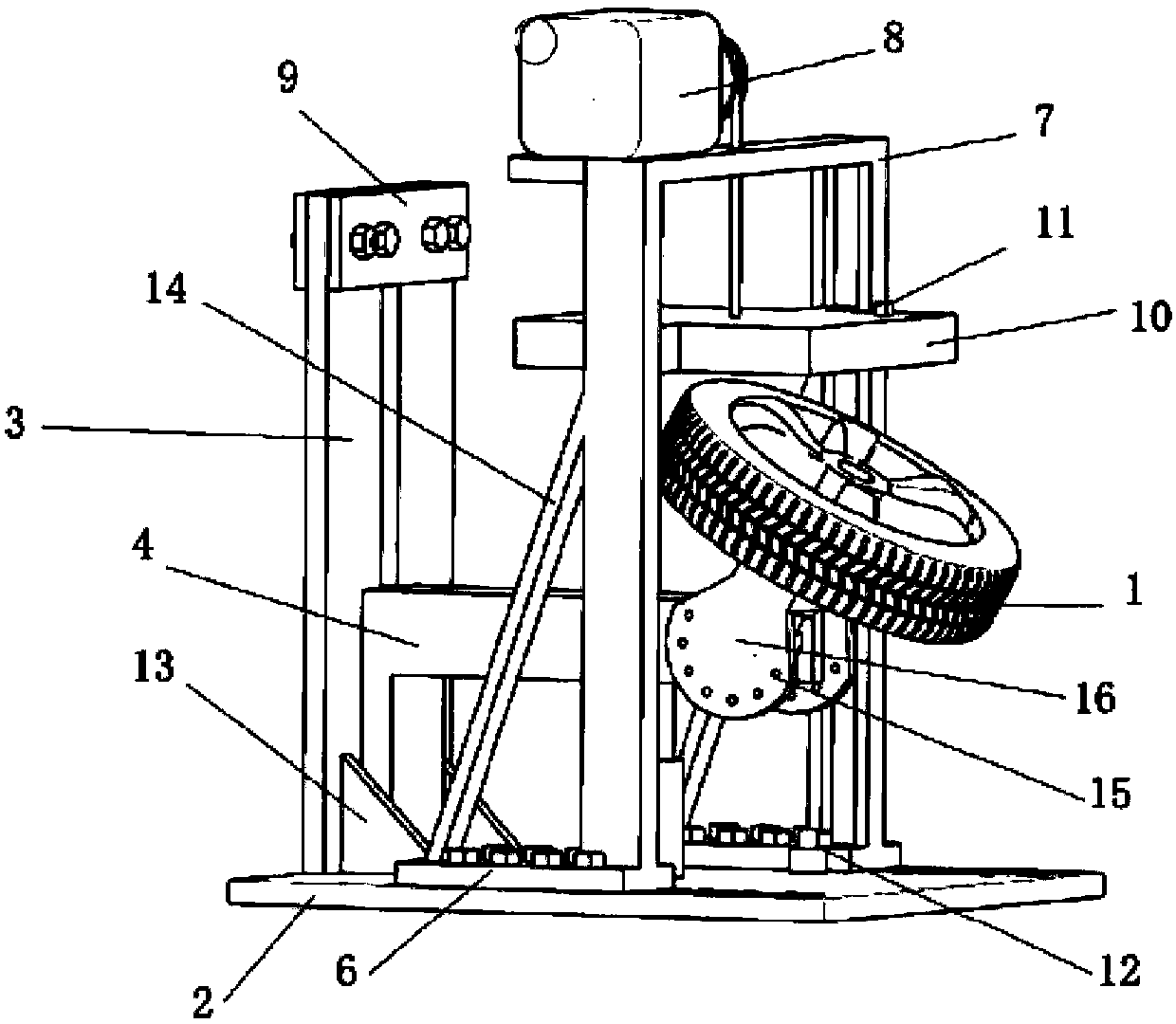

[0026] Attached below Figure 1-4 A multi-angle tire dynamic stiffness testing device of the present invention is further described in detail.

[0027] For a multi-angle tire dynamic stiffness test device of the present invention, please refer to the attached Figure 1-4 , comprising a supporting device, a fan-shaped plate 16, a T-shaped shaft 17 and a punching device, the supporting device is fixed to the ground or an installation surface, the angle of the fan-shaped plate 16 is adjustable at the right end of the supporting device, and the supporting device is connected to the The T-shaped shaft 17 is hinged, the fan-shaped plate 16 is fixed to the T-shaped shaft 17, the tire 1 is sleeved on the right end of the T-shaped shaft 17, the tire 1 is arranged in the stamping device, and the stamping The top of the device is provided with a driving device, the driving device is connected to the upper part of the stamping device, the upper part of the stamping device is releasably o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com