Project quality management evaluation method for comprehensive pipe gallery

A technology of engineering quality and comprehensive pipe gallery, applied in data processing applications, instruments, resources, etc., can solve the problems of inconsistent engineering quality management evaluation forms and low accuracy of evaluation results, so as to reduce the tendency and the influence of errors, improve the Accuracy and uniformity of form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

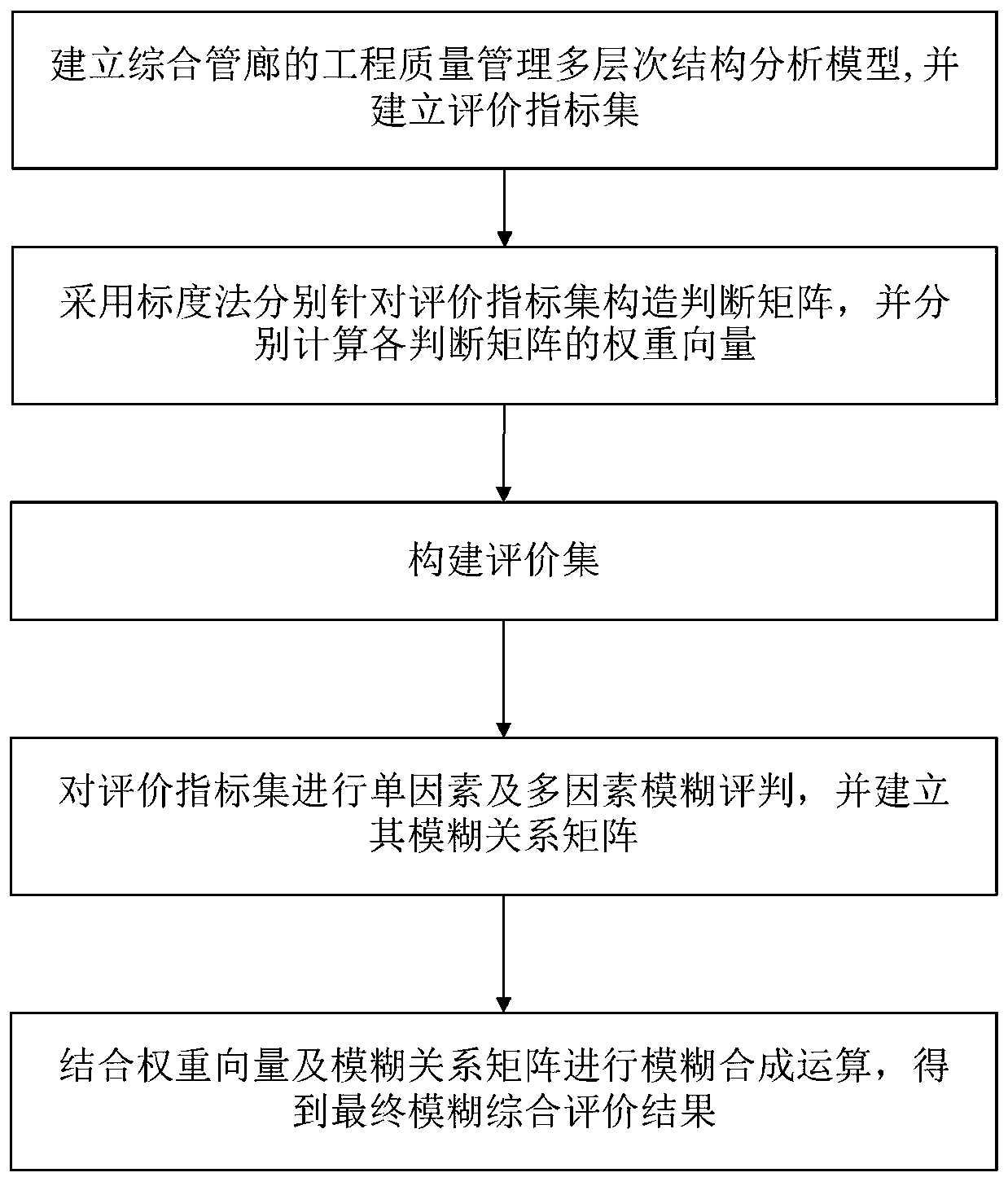

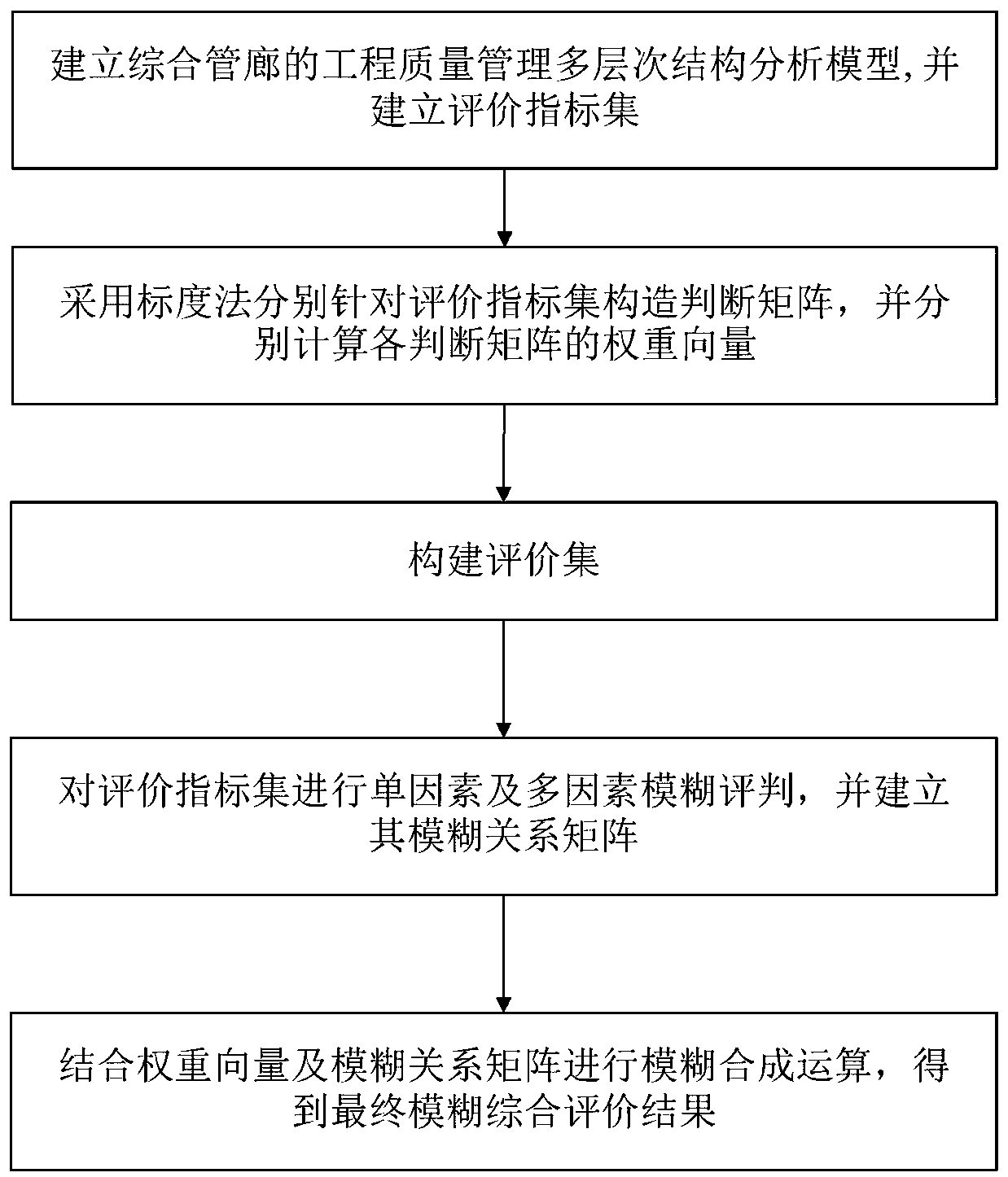

[0053] Embodiment 1: An engineering quality management evaluation method for a comprehensive utility gallery, comprising the following steps:

[0054] Step 1: Establish a multi-level structure analysis model for the engineering quality management of the integrated pipe gallery, including the target layer, criterion layer, index layer and sub-index layer;

[0055] The target layer includes the quality management evaluation indicators of the participating units of the comprehensive utility gallery project;

[0056] The criterion layer includes two evaluation indicators of quality behavior and entity quality of participating units;

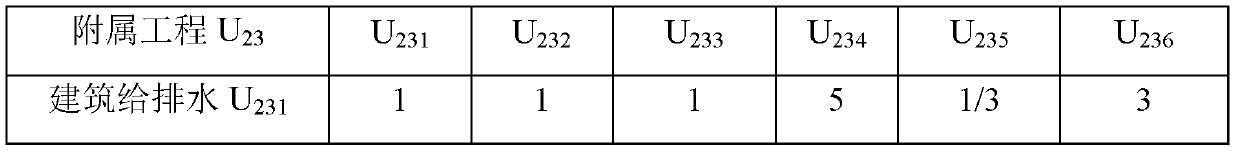

[0057] The indicator layer includes multiple evaluation indicators corresponding to the quality behavior of participating units, and three evaluation indicators of the physical quality of participating units: foundation and foundation engineering, main structure and auxiliary engineering;

[0058] The sub-indicator layer includes a plurality of sub-...

Embodiment 2

[0114] Embodiment 2: application embodiment (1)

[0115] When the participating unit is the construction unit, the implementation steps in Example 1 are adopted to evaluate the project quality management of the comprehensive utility gallery;

[0116] In step 1, an evaluation index set U is established for the criterion layer, U=U k , k=1,2; establish a subset of the rating index set U for the index layer and the sub-index layer;

[0117] Specifically, the quality behavior indicators of the construction unit index layer include personnel management, technical management, material management, subcontract management, construction management, data management, and acceptance management, and the physical quality of the construction unit index layer includes foundation and foundation engineering , main structure and ancillary engineering three evaluation indicators; the index layer uses a set to represent U kd (k=1,2; d=1,2,3,4...);

[0118] The sub-indicator layer of the construc...

Embodiment 3

[0171] Embodiment 3: application embodiment (two)

[0172] When the participating unit is the supervision unit, take the steps in Embodiment 1 to carry out the project quality management evaluation of the comprehensive utility gallery;

[0173] In step 1, an evaluation index set U is established for the criterion layer, U=U k , k=1,2; establish a subset of the rating index set U for the index layer and the sub-index layer;

[0174] Specifically, the quality behavior indicators of the supervision unit index layer include supervision quality assurance system and personnel quality management, technical management, quality management, data management, engineering materials / components / equipment and inspection management, and acceptance management; the supervision unit indicators Three evaluation indexes of foundation and foundation engineering, main structure and ancillary engineering of layer entity quality; the index layer represents U kd (k=1,2; d=1,2,3,4...);

[0175] The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com