Device and method for detecting and/or examining an abrasion on the surface of a cylindrical component

A cylindrical and component technology, applied in the direction of measuring devices, using optical devices, reducing greenhouse gases, etc., can solve the problems of time-consuming, damage, etc., and achieve the effect of low cost and low equipment technology consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

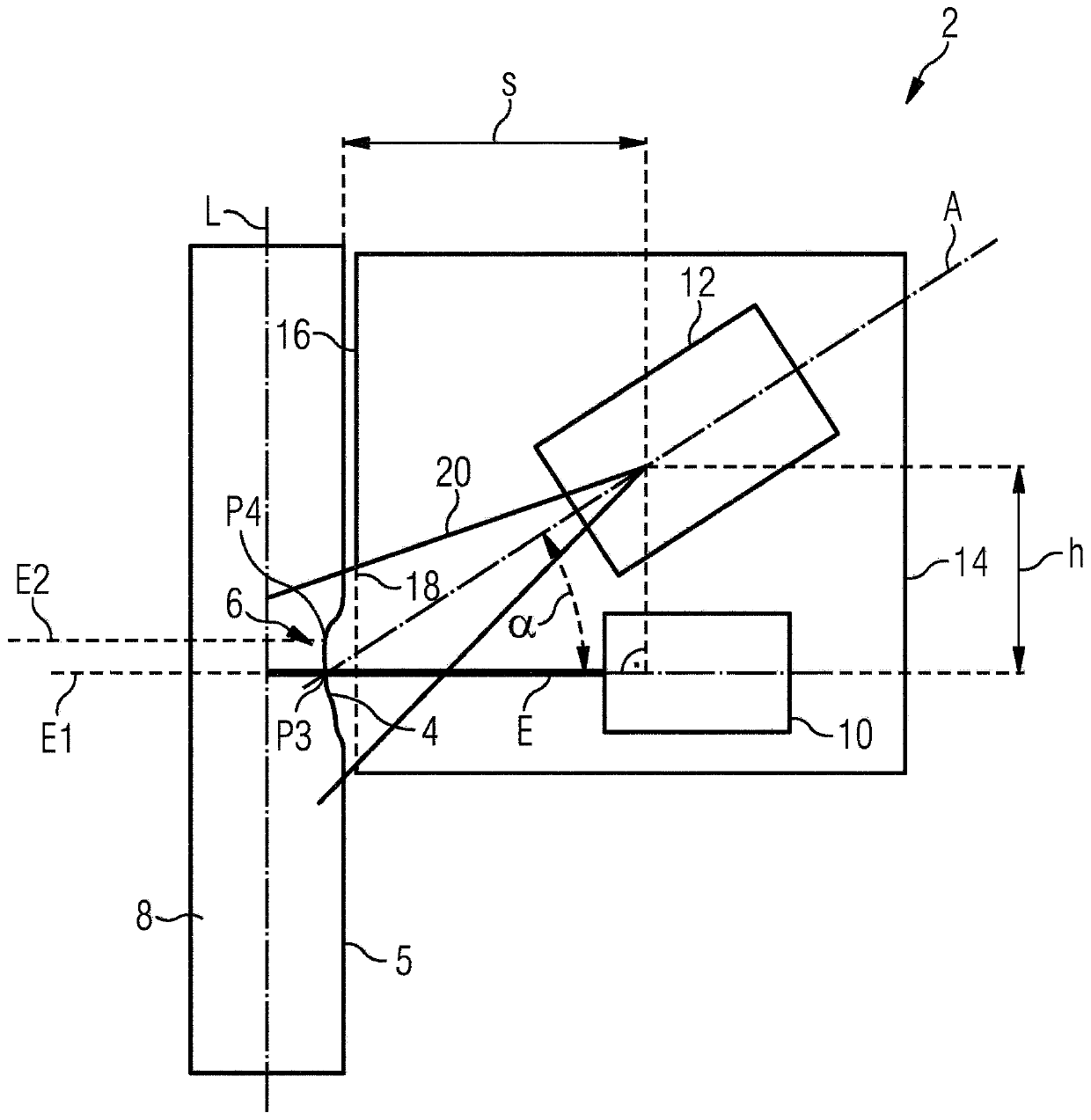

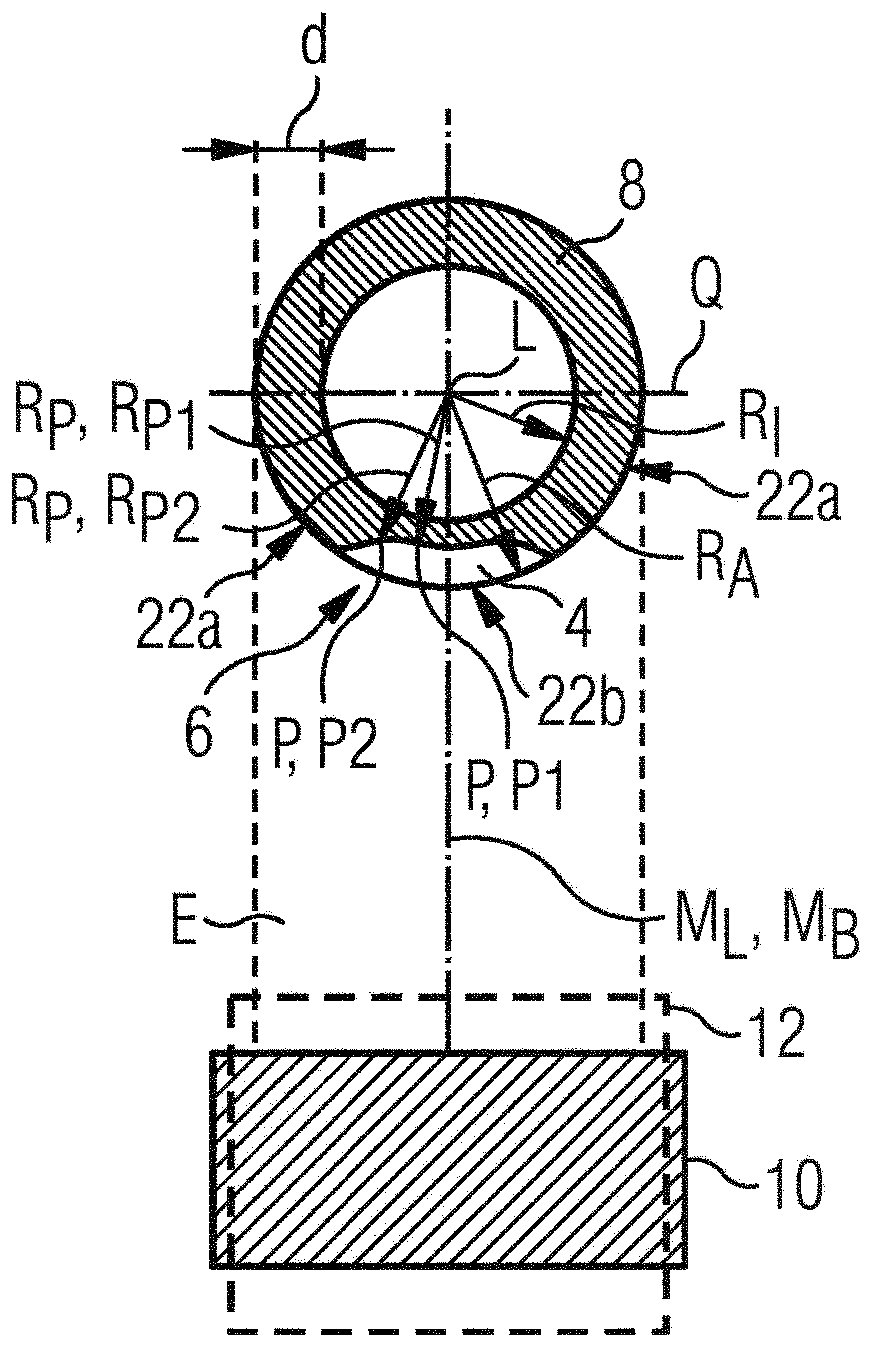

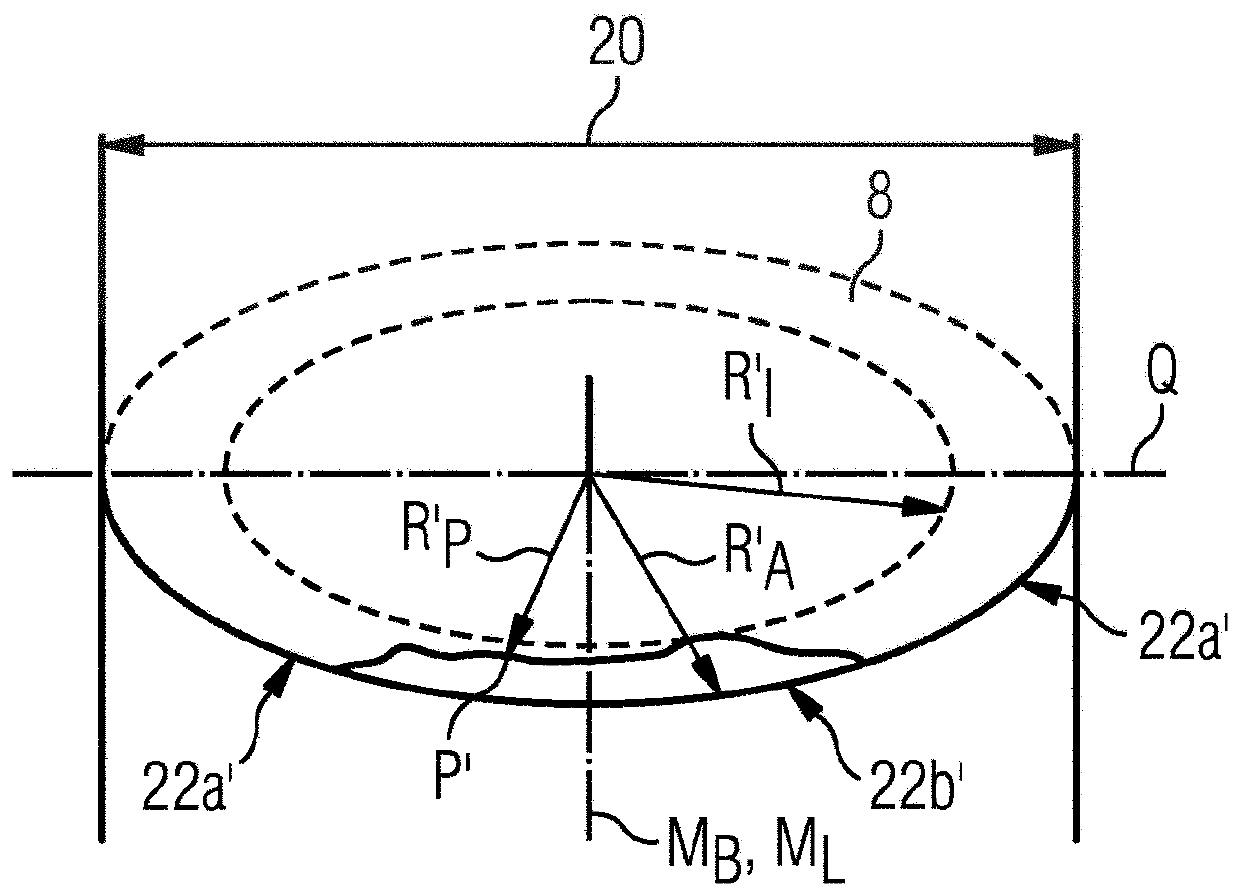

[0032] figure 1 A device 2 for detecting and inspecting wear 4 that occurs on a surface 5 of a cylindrical part 8 is shown. The cylindrical part 8 is currently the fuel rod of a pressurized water reactor. The device 2 comprises a light source 10 which projects light onto a surface region 6 of a cylindrical part 8 in which wear 4 has occurred. The light source 10 is a slit lamp which emits light in the beam plane E and illuminates the surface region 6 with this light. In order to detect an image of the surface area 6 illuminated by the light beam, the device 2 has an image detection unit 12 in the form of a camera. The optical axis A of the image detection unit 12 is oriented at an angle α to the beam plane E. As shown in FIG. The current angle α is about 35°. Furthermore, the image detection unit 12 is arranged at a distance h above the beam plane E, wherein the distance h relates to the point at which the optical axis A of the image detection unit 12 intersects the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com