A diesel engine in-cylinder pressure feedback control device, control system and method

A feedback control system and in-cylinder pressure technology, applied in the control field, can solve the problems of not being able to prompt the wear of a single injector, increase in fuel consumption, and deterioration of fuel injector combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

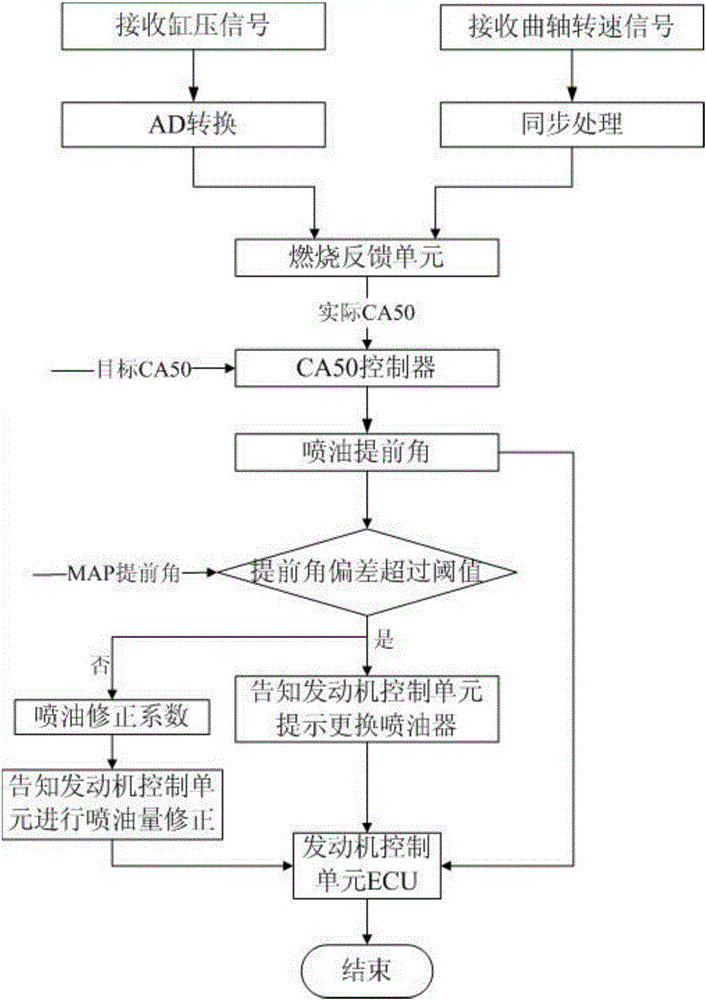

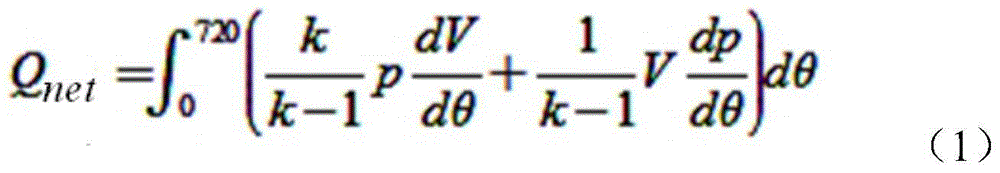

Method used

Image

Examples

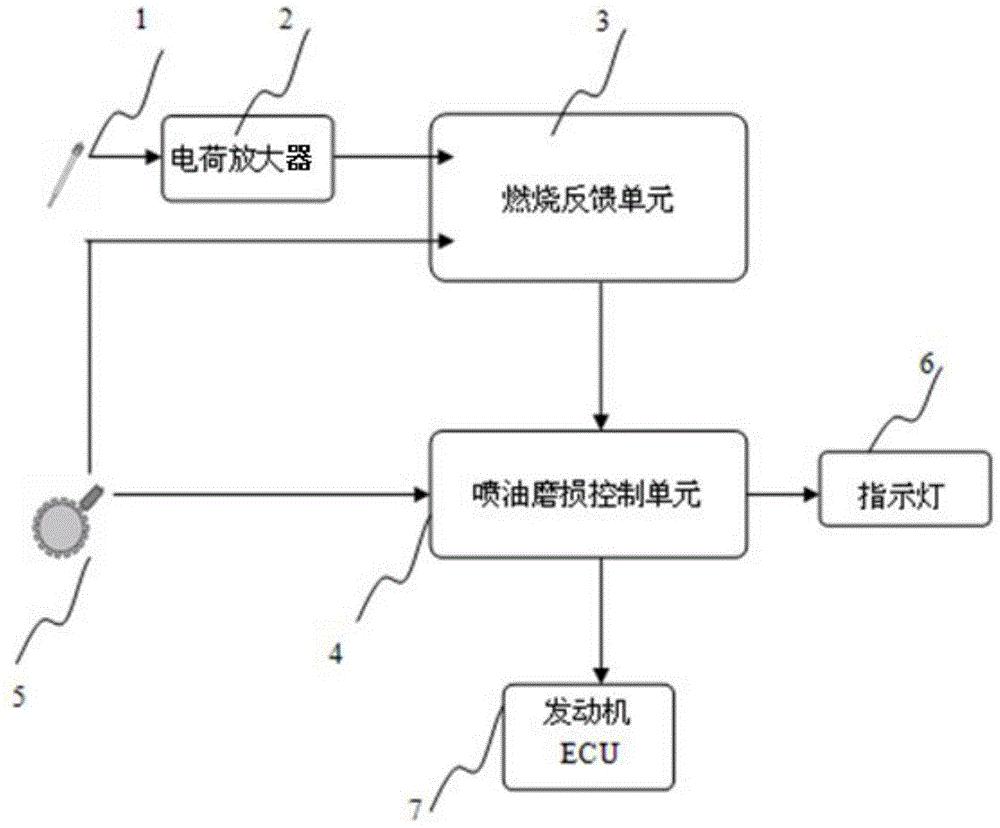

Embodiment 1

[0050] The diesel engine in-cylinder pressure feedback control device of the present invention includes a cylinder pressure sensor device for each cylinder of the engine, a combustion feedback unit 3 , a fuel injection wear control unit 4 , an angle marker 5 , and an indicator light 6 . The cylinder pressure sensing device includes a cylinder pressure sensor 1 and a charge amplifier 2. The cylinder pressure sensor 1 is a sensor whose output signal is a charge signal, and its output is connected to the input of the charge amplifier 2. The pressure in the cylinder is passed through the pressure inside the sensor. The transistor is converted into a charge signal, and the charge signal is converted into a 0-10v voltage signal through the charge amplifier 2 . The outputs of the charge amplifier 2 and the angle marker 5 are connected to the combustion feedback unit, the output of the combustion feedback unit 3 is connected to the input of the fuel injection wear control unit 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com