Method, system and device for in-cylinder pressure feedback control of diesel engine

A technology of in-cylinder pressure and feedback control, applied in the field of control, can solve problems such as inability to prompt the wear of a single fuel injector, failure to fully identify the wear of a single fuel injector, and increased fuel consumption

Active Publication Date: 2014-11-19

CHINA FIRST AUTOMOBILE

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Some international suppliers such as BOSCH, denso and other companies, their control computer diagnosis strategy will judge the fuel injector wear according to the fuel supply status of the oil pump, and prompt the user for maintenance, but cannot prompt the wear of a single fuel injector, and cannot fully identify a single fuel injector at the repair station. For the wear of the injector, the method of replacing all the injectors is usually adopted, which puts the user under great economic pressure

At the same time, the wear of the injector will lead to the deterioration of combustion and the increase of fuel consumption. At present, BOSCH, denso and other companies have not carried out fuel injection correction, which is the main reason for the increase of fuel consumption.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

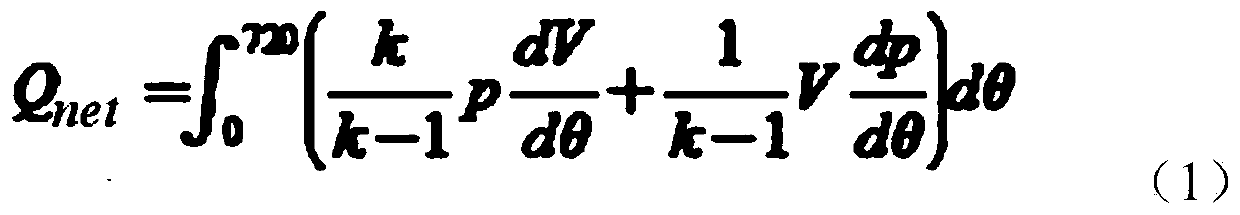

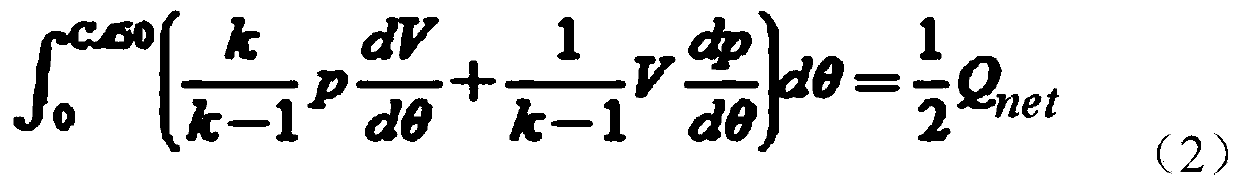

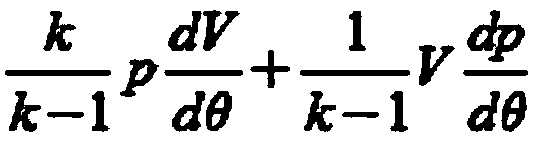

The invention relates to a method, a system and a device for in-cylinder pressure feedback control of a diesel engine. An angle marker and each cylinder pressure sensing device of the control device are connected with an input of a combustion feedback unit; an output of the combustion feedback unit is connected to an input of a fuel injection abrasion control unit; an output of the fuel injection abrasion control unit is connected to indicator lamps. The combustion feedback unit calculates a combustion phase CA50 of each cylinder according to cylinder pressure signals and crankshaft turn angle signals, the fuel injection abrasion control unit compares a current fuel injection advance angle of each cylinder with an initial value of the fuel injection advance angle, and when the deviation value exceeds a threshold, the fact that a fuel injector is in excessive abrasion can be judged, and a signal is outputted to control the corresponding indicator lamp to be turned on. By the aid of the method, the system and the device for in-cylinder pressure feedback control of the diesel engine, abrasion judgment of the single fuel injector can be realized, a user is reminded of replacing the fuel injector when the fuel injector is in excessive abrasion, and accordingly utilization and maintenance cost can be saved for the user.

Description

Technical field The invention belongs to the field of control technology, and relates to an in-cylinder pressure feedback control device, control system and method that can be used in heavy-duty diesel engines and light-duty diesel engines. Background technique Currently, diesel engine cylinder pressure feedback control technology is in the research stage in China, mainly based on low temperature combustion technology based on cylinder pressure feedback control. Foreign countries mainly apply cylinder pressure feedback control technology in low-temperature combustion fields such as HCCI, which can effectively control the combustion state in the cylinder and make low-temperature combustion stable and efficient. At the same time, the cylinder pressure feedback control technology can also be applied to improve the unevenness of each cylinder, improve the system dispersion, improve the fuel adaptability of the engine, monitor the combustion state, and quickly calibrate the fuel in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02D41/22F02D41/38

Inventor 张建锐窦慧莉佀庆涛虞卫飞于拓舟刘斌

Owner CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com