Coldness control device and method for material bowl of ice cream machine and ice cream machine of coldness control device

An ice cream machine and bowl technology, applied in frozen desserts, food science, applications, etc., can solve the problems of small flow design, limited refrigeration capacity and cooling speed of the bowl, and affect the food safety of ice cream slurry, so as to reduce energy consumption , reduce food safety risks, and maintain freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

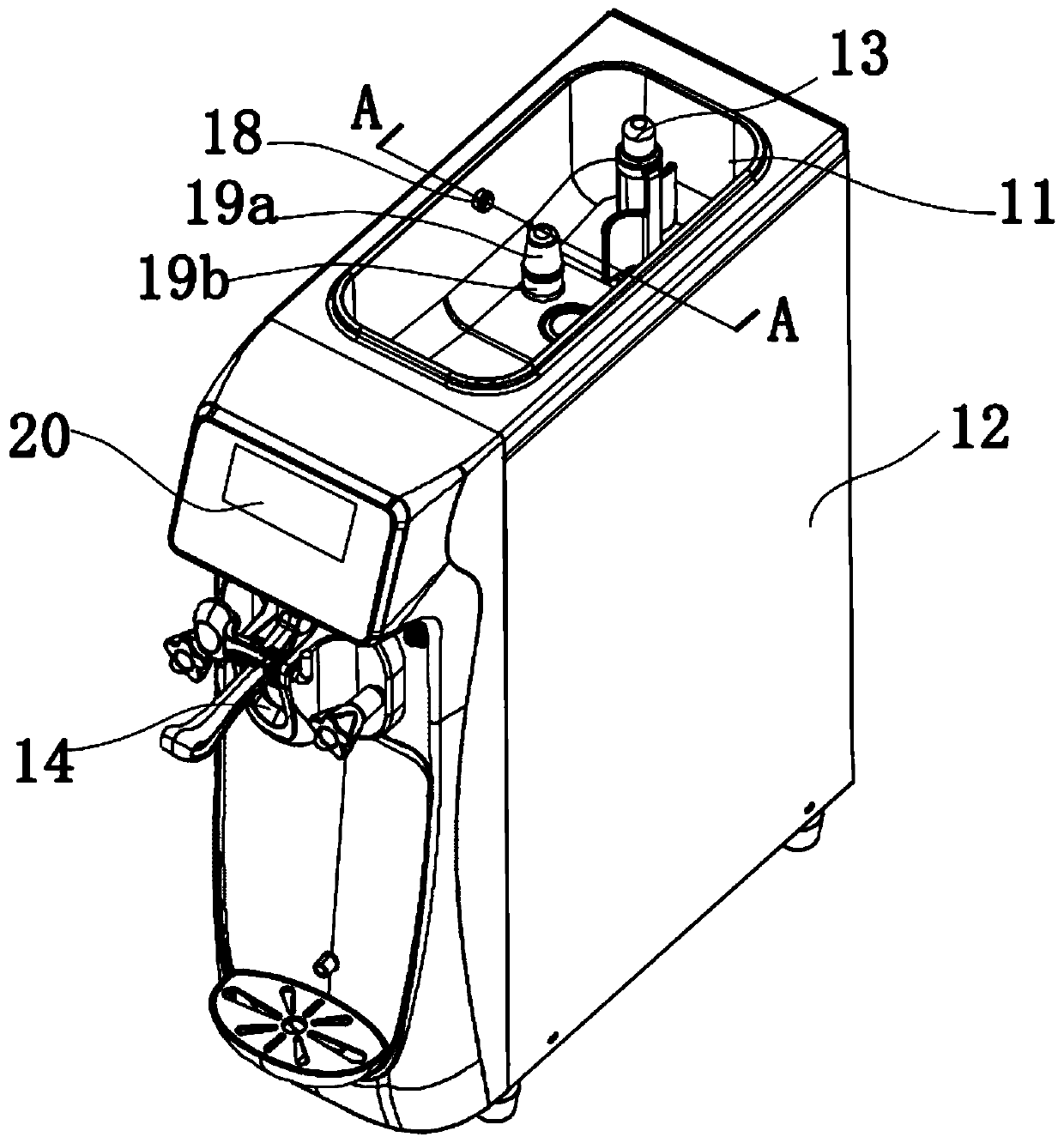

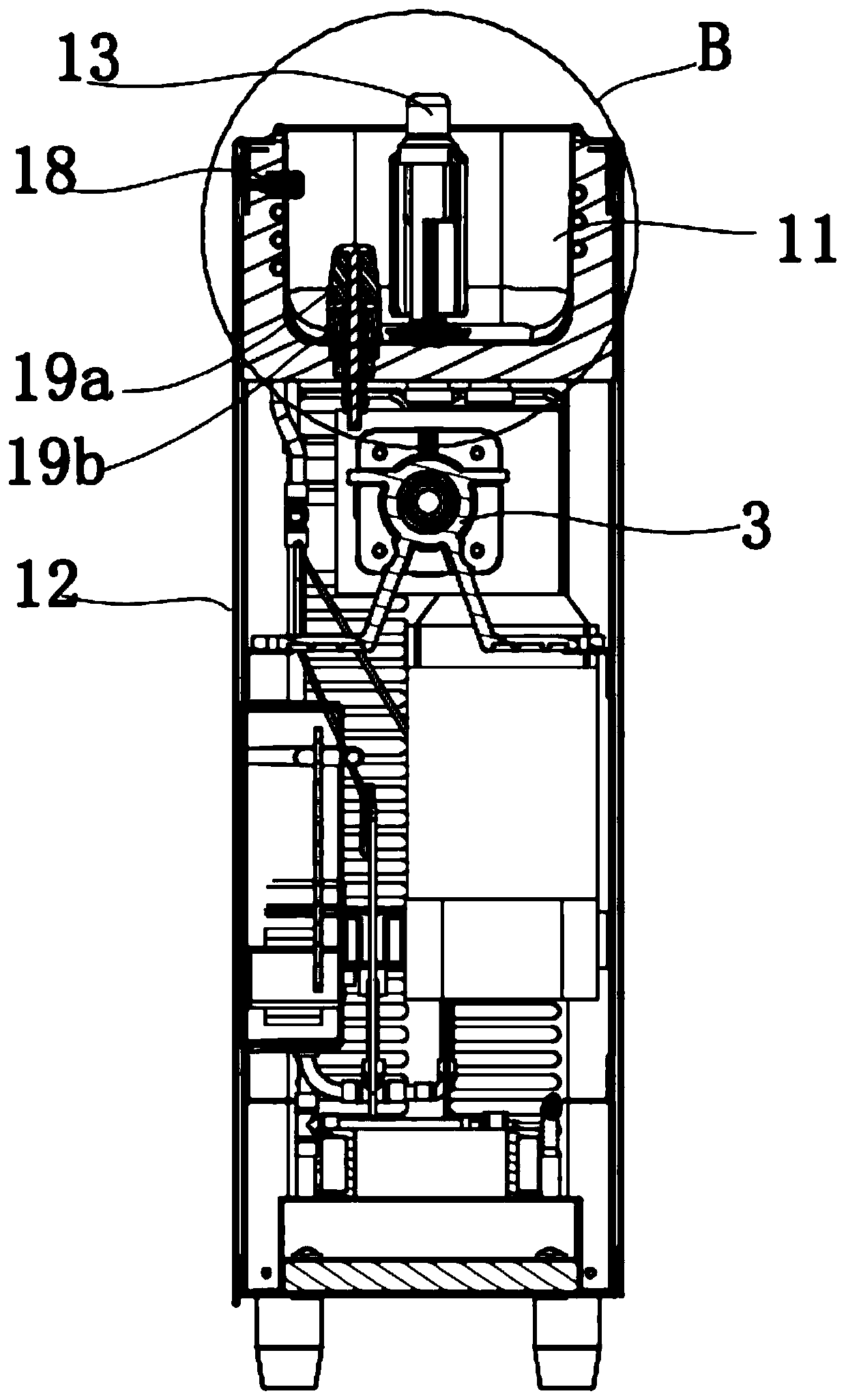

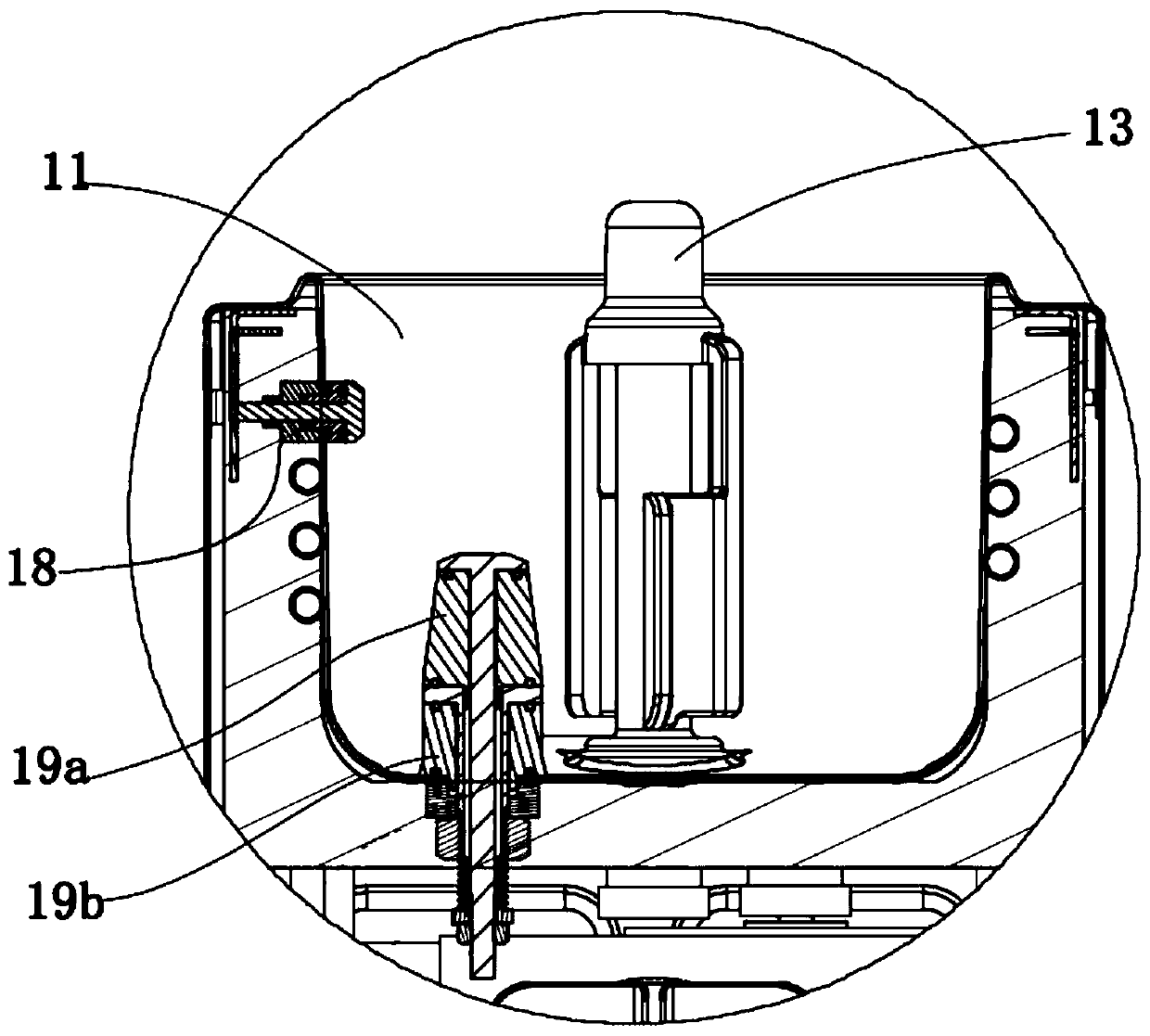

[0049] Ice cream machine of the present invention such as Figure 1 to Figure 5 As shown, the ice cream machine includes a fuselage 12, a material basin 11, a material basin agitator 13, a material basin stirring motor, a freezing cylinder 3, a freezing cylinder agitator, a freezing cylinder stirring motor, a discharge head 14, an electric control board, a control The display board 20, the material basin agitator 13 is installed in the material basin 11, is connected with the material basin stirring motor, the freezing cylinder agitator 14 is inserted in the freezing cylinder 3, is connected with the freezing cylinder stirring motor, and the material basin 11 is arranged with it The feed basin cover 8 matched in shape, and the electric control main board are used to control the actions of each part.

[0050] The cooling control device in this embodiment includes a compressor 1, a condenser 2, a material basin evaporator 4, a freezing cylinder refrigeration inlet pipe 31 and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap