Heating method for electronic cigarette

A heating method and technology for electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of poor taste of electronic cigarettes, the influence and harm of the surrounding environment and crowd of smokers, etc., so as to reduce the emission of harmful substances, improve the taste of smoking, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

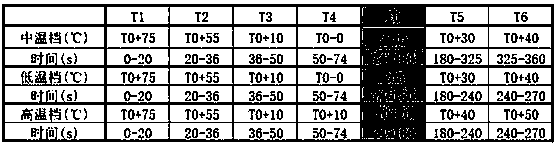

[0011] The following is the normal temperature value T under the current conditions 0 is 25°C, the temperature target value T of e-cigarette heating 1 is 265°C, and the resistance value of the heating core of the electronic cigarette at normal temperature is R 0 , when heated to a high temperature state, the resistance value is R 1 . From this, it is determined that the temperature coefficient of resistance (TCR) of the electronic cigarette is TCR value = (R 1 -R 0 ) / (R 0 *(T 1 -T 0 )). The voltage of the square wave output by the PWM module is 8VDC, and the frequency is 25Hz.

[0012] The PWM module with adjustable duty cycle outputs a high level to apply voltage to the heating core, and the heating core is used to heat the electronic cigarette; at the moment when the square wave output by the PWM module is at a high level, the MCU of the electronic cigarette reads the heating The voltage value of the two electrodes of the core to get the actual heating voltage V of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com