Mobile pulse dust collector

A pulse dust collector, mobile technology, applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve problems such as difficult to dissipate and a large amount of dust, reduce the time of dust cleaning, improve the effect of dust removal, and protect the body Healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

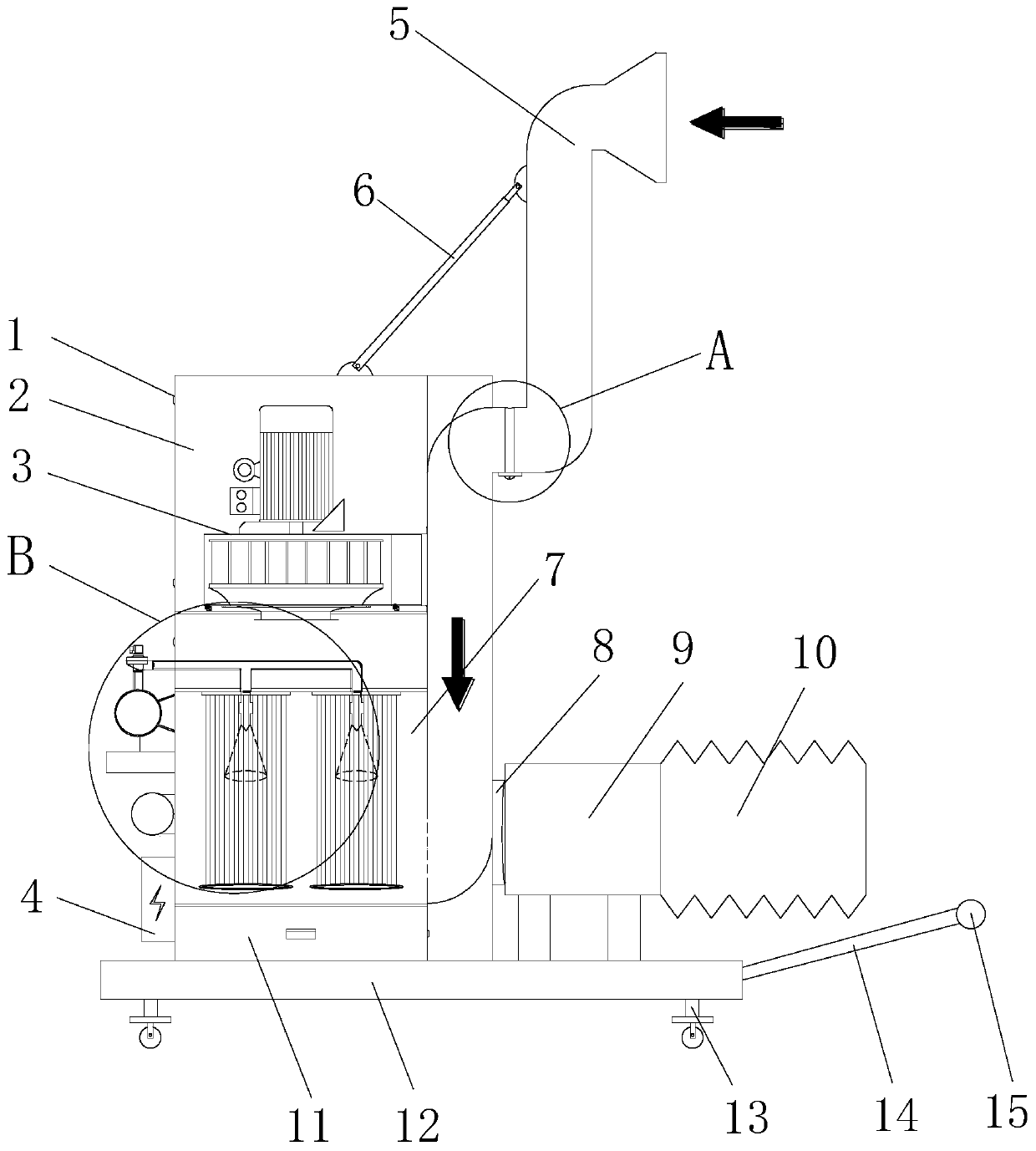

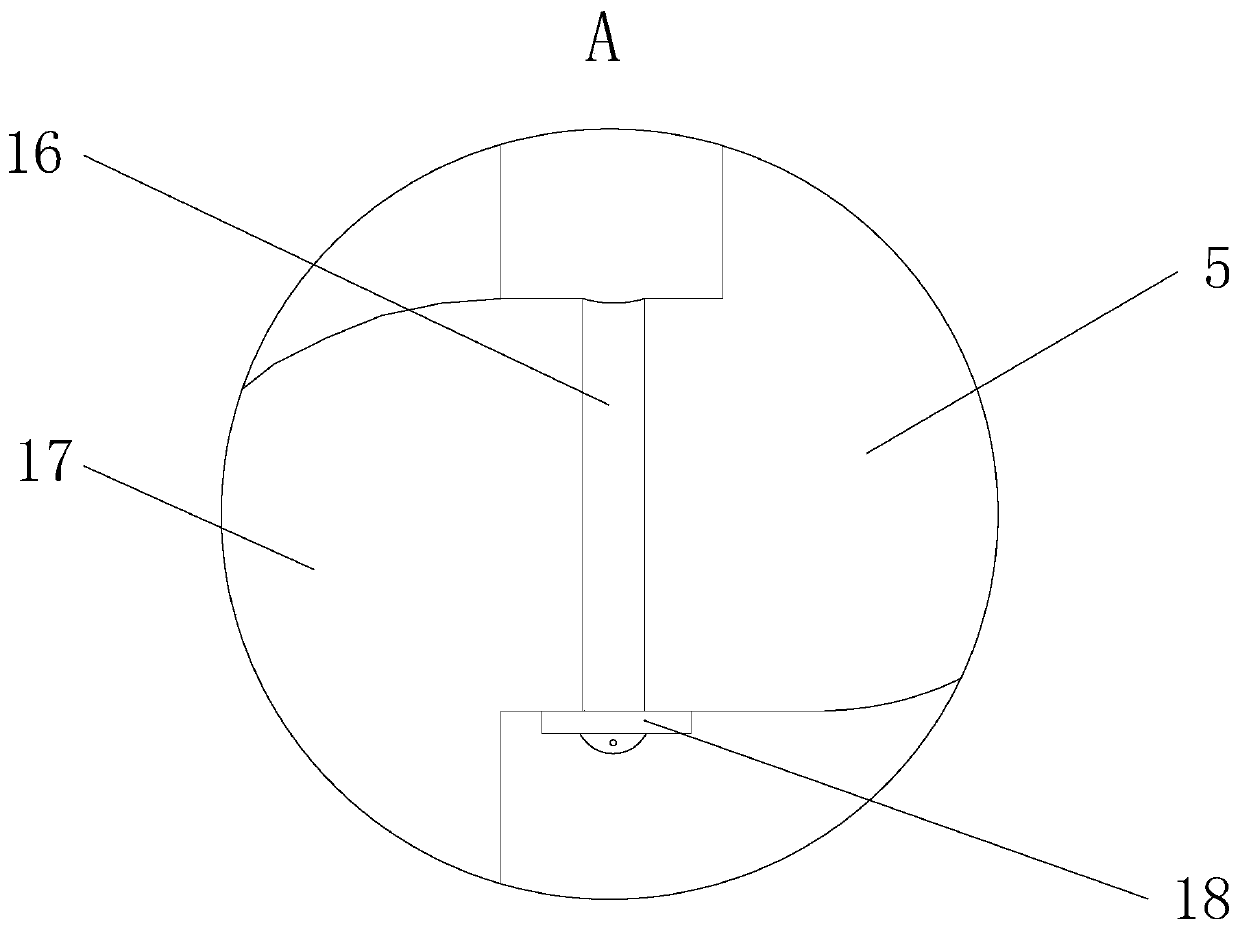

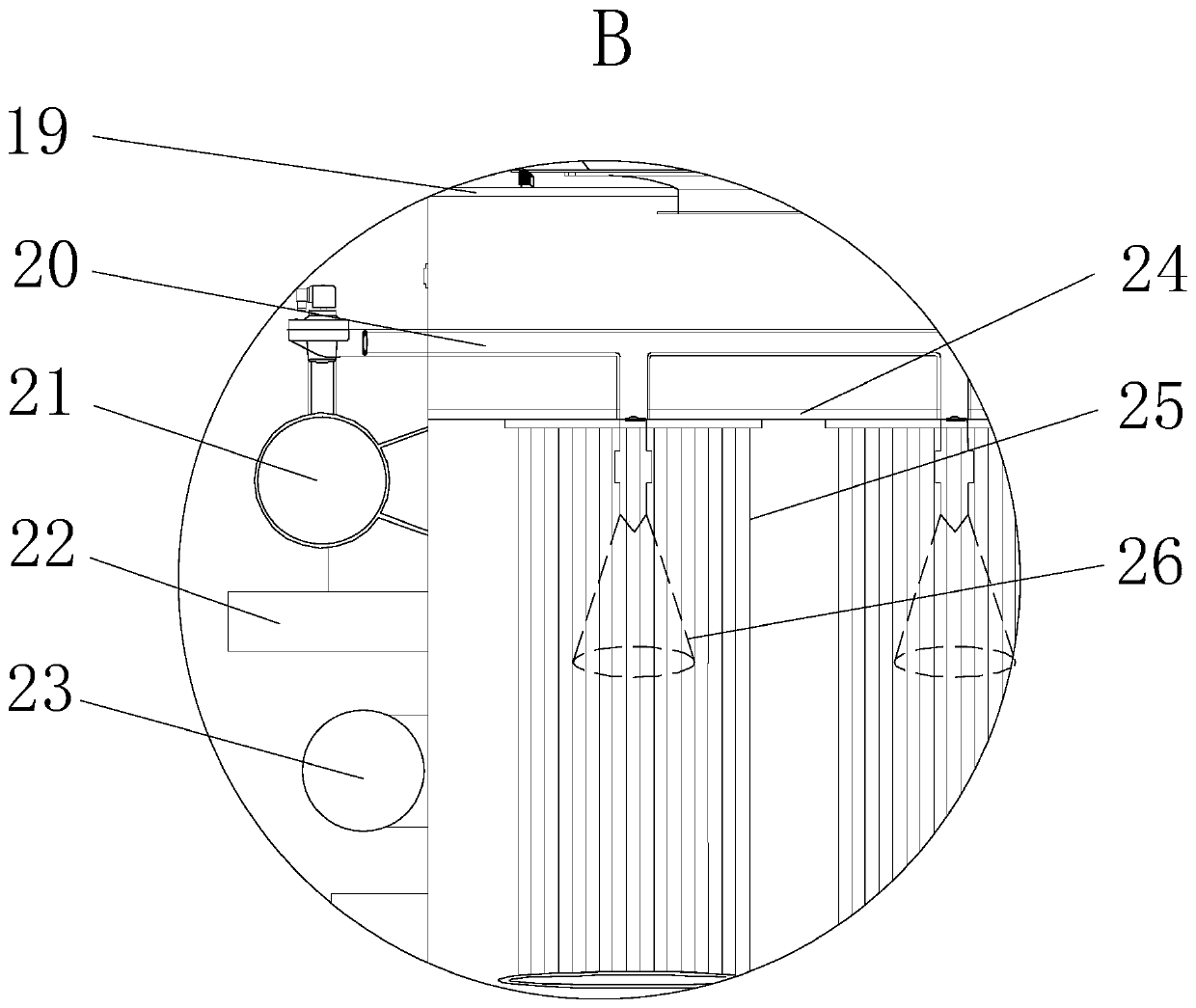

[0022] The mobile pulse dust collector, as shown in the figure, includes a box body 1, a centrifugal fan 3, a filter cartridge 25, an air inlet pipe 17 and an air outlet pipe 8, and the box body 1 is provided with an air inlet pipe 17 and an air outlet pipe 8, The box body 1 is provided with an upper chamber 2 and a lower chamber 7, the upper chamber 2 communicates with the air outlet pipe 8, the lower chamber 7 communicates with the air inlet pipe 17, the upper chamber 2 is provided with a centrifugal fan 3, and the lower chamber 2 communicates with the air outlet pipe 17. The cavity 7 is provided with a filter cartridge 25 , and the centrifugal fan 3 is located above the filter cartridge 25 .

[0023] A bracket 19 and a fixing plate 24 are arranged inside the box body 1 , a centrifugal fan 3 is arranged on the bracket 19 , and a filter cartridge 25 is arranged on the fixing plate 24 . The box body 1 is provided with a dust collection drawer 11 , and the dust collection drawe...

Embodiment 2

[0031] Same as embodiment 1, the difference is that the number of filter cartridges 25 is 4, the number of spray heads 26 is 4, and the number of pulse generators 23 is 4.

Embodiment 3

[0033] Same as embodiment 1, the difference is that the number of filter cartridges 25 is 6, the number of spray heads 26 is 6, and the number of pulse generators 23 is 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com