Water gun device

A water gun and body technology, applied in spraying devices, single handheld devices, etc., can solve the problems of unpredictable flushing time, no stable place for water guns, etc., and achieve easy access, easy installation and disassembly, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

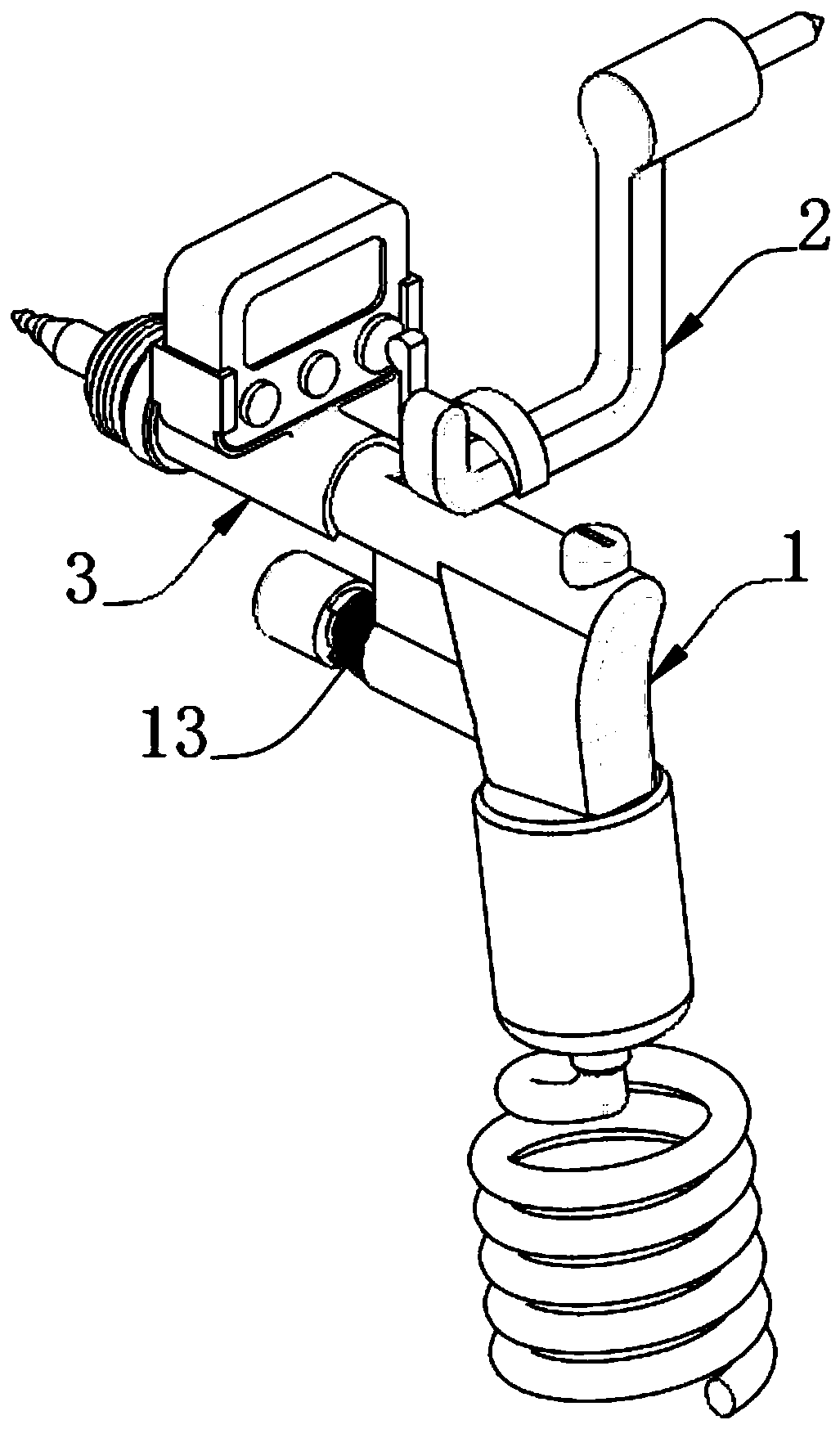

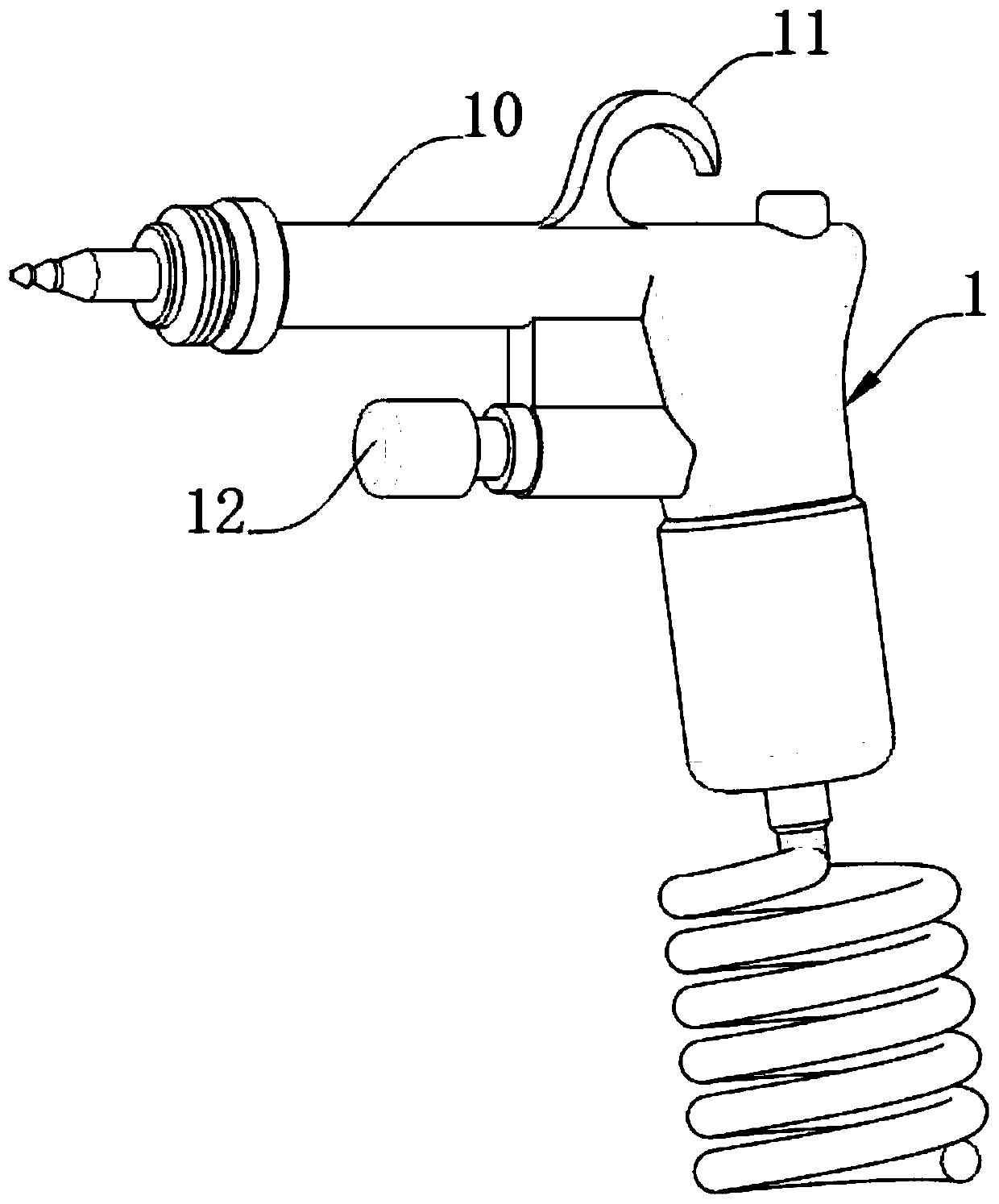

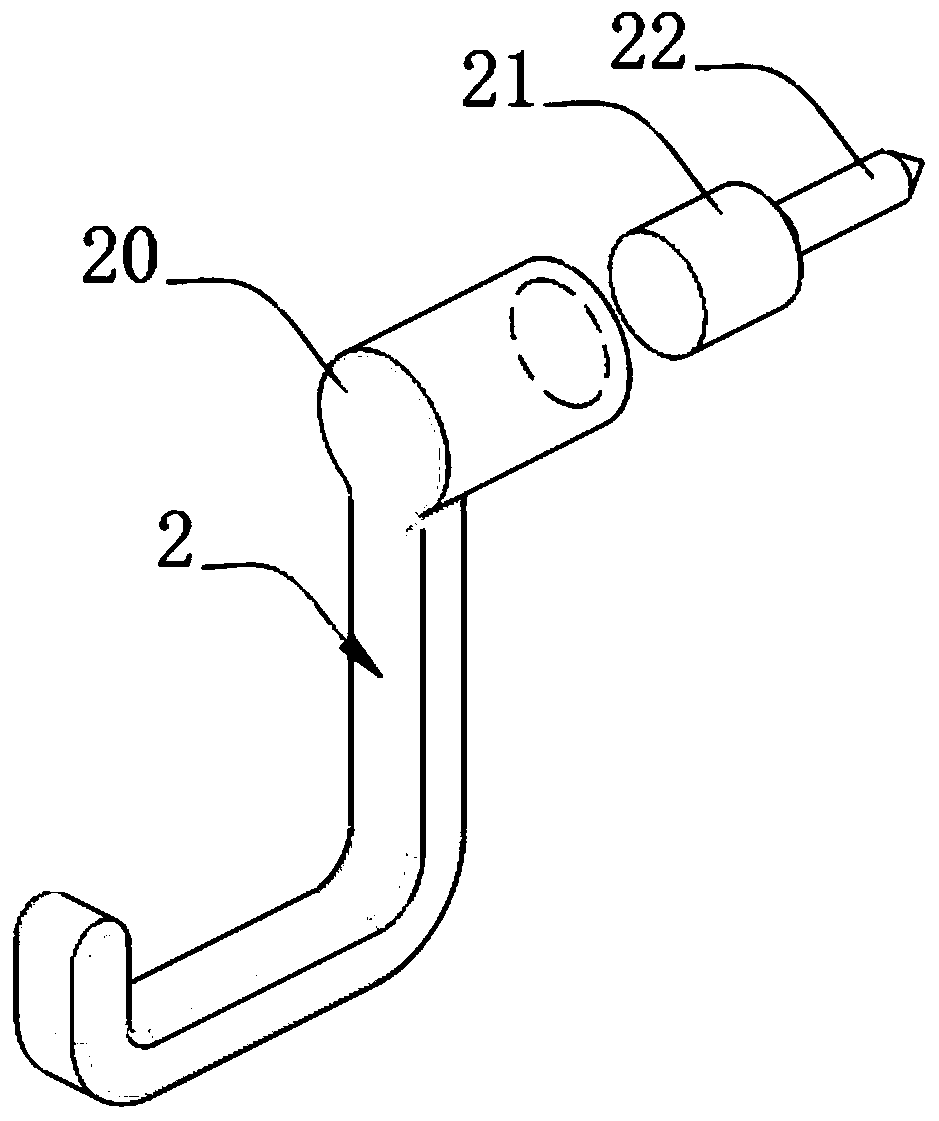

[0026] A water gun device. In order to facilitate the placement of the water gun body 1 conveniently and stably, the inventor sets a fixing hook 2 as a preferred embodiment, such as figure 1 , figure 2 with image 3 As shown, the water gun body 1 is included. A fixed hook 2 is provided above the water gun body 1. The water gun body 1 includes a water gun tube 10, the top side of the water gun tube 10 is welded with an arc-shaped hook 11, and a trigger 12 is installed on one side of the water gun body 1 A spring 13 is sleeved on one side of the trigger 12, a sleeve 20 is provided on the top of the fixed hook 2, a sleeve post 21 is inserted into the inner side of the sleeve 20, and a pointed post 22 is embedded at one end of the sleeve post 21.

[0027] In this embodiment, the fixing hook 2 is made of PP, that is, polypropylene, which is light in weight, good in toughness, and rigid in strength. The pointed post 22 is made of iron material, and the sleeve post 21 and the pointed pos...

Embodiment 2

[0031] As a second embodiment of the present invention, in order to facilitate the timing of flushing, the inventor has provided a timing seat 3 as a preferred embodiment, such as Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, one side of the fixed hook 2 is provided with a timing seat 3, the top surface of the timing seat 3 is provided with a clamping plate 30, one end of the timing seat 3 is provided with a rotating column 31 outside, and one side of the rotating column 31 is provided with a linkage rod 32 , The bottom end of the linkage rod 32 is provided with a collar 320, the collar 320 is snap-fitted with the trigger 12, the middle section of the linkage rod 32 is provided with a swivel 321, the swivel 321 is inserted into the pivot 31, and the top of the linkage rod 32 An arc block 322 is provided on one side.

[0032] In this embodiment, the timing seat 3 is made of PP material, namely polypropylene, which is light in weight, good in toughness, and rigid in str...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap