A crack plugging agent based on expandable particles and curable particles

A technology of expanding particles and curing agent, applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve the problem of water blocking effect, weak force between expanding particles and reservoir rocks, and particle back spitting. and other problems, to achieve the effect of wide reservoir applicability, outstanding temperature and salt tolerance, and improved breakthrough pressure gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

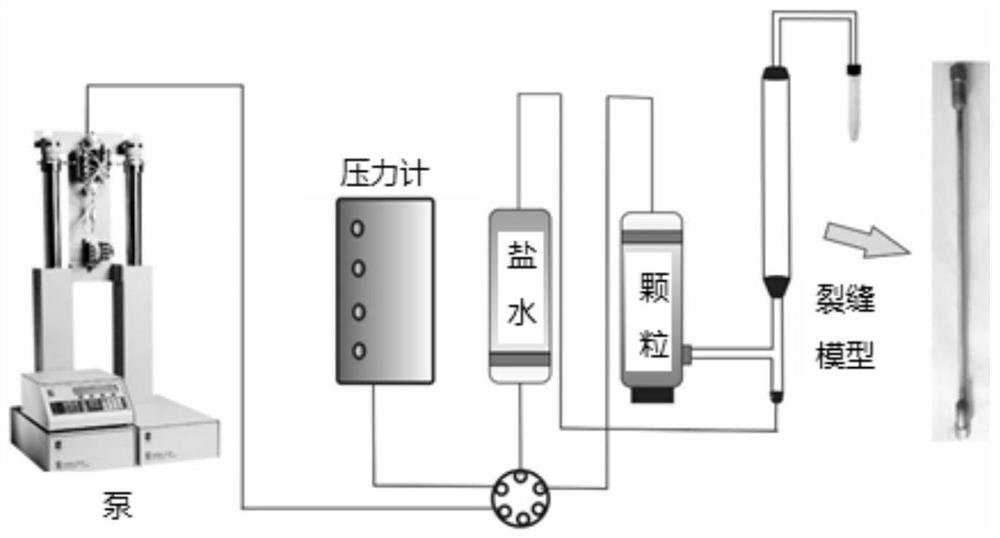

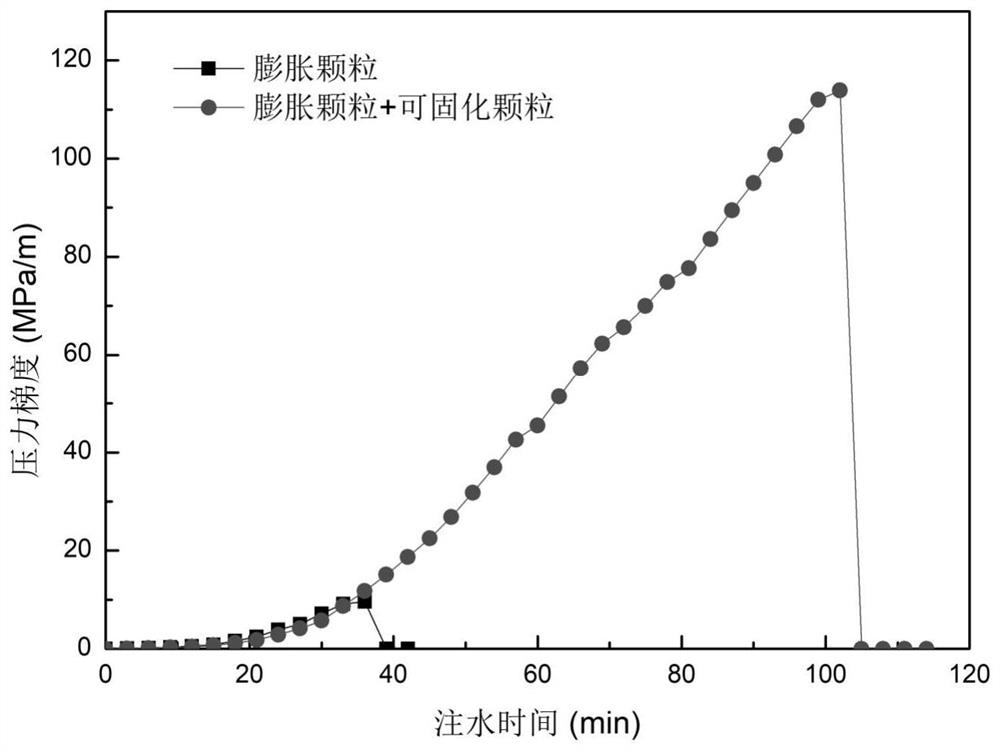

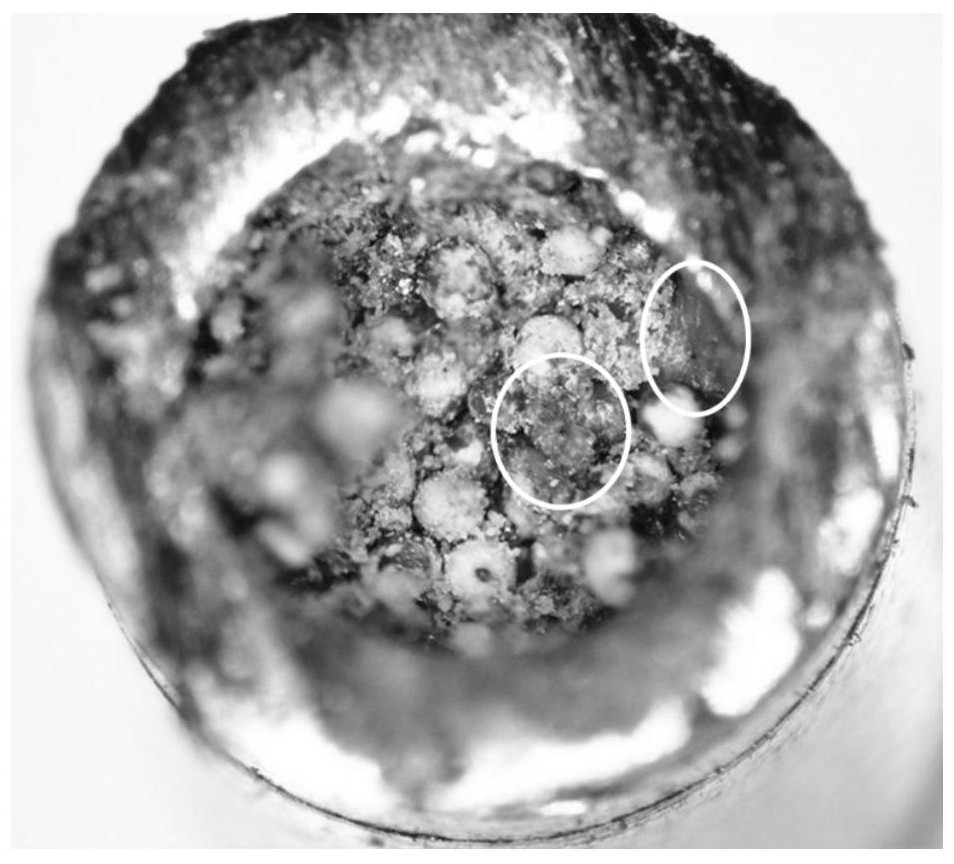

Method used

Image

Examples

Embodiment 1

[0028] Add 8g of acrylamide, 2g of 2-acrylamido-2-methylpropanesulfonate, and 1g of N-vinylpyrrolidone into 69g of clear water and stir evenly, then add 0.03g of ammonium persulfate, 0.03g of N,N-methylenebis Acrylamide, after it is fully dissolved, add 20g of nano-montmorillonite, stir evenly again and put it into a 60°C oven for 5h to form a gel block, granulate and crush the gel block into particles with a diameter of 0.85mm to 1mm to obtain this product Invented expanded particles A1.

[0029] Put 20g of 2mm pumice balls into a glass bottle and preheat it in a thermostat to 120°C; add 2g of phenolic resin powder into the preheated pumice and mix well; heat the mixture in an oven at 170°C and take it out every 20 minutes Mix it once, take it out after 2 hours, cool it, and separate it to obtain curable particles B1 of the present invention.

[0030] Hexamethylenetetramine is used as the curing agent C1 of the present invention.

[0031] Keep A1, B1, and C1 separately, and...

Embodiment 2

[0033] The gel block prepared in the process of preparing the expanded granule A1 in Example 1 was granulated and crushed into particles with a diameter of 0.6-0.8 mm to obtain the expanded granule A2 of the present invention.

[0034] Put 20g of 0.4-0.6mm ceramsite into a glass bottle and preheat it to 120°C in a constant temperature box; add 1.5g of phenolic resin powder into the preheated ceramsite and mix well; put the mixture in a 170°C Heating in an oven, taking out and mixing once every 20 minutes, taking out after 2 hours for cooling, and separating to obtain the curable particles B2 of the present invention.

[0035] Paraformaldehyde is used as the curing agent C2 of the present invention.

[0036] Store A2, B3, and C2 separately, and the combination is a crack plugging agent based on expanding particles and curable particles. When using, first disperse / dissolve the expanding particles A2, curable particles B2, and curing agent C2 in The 20% NaCl solution is sequenti...

Embodiment 3

[0038] Add 12g of acrylamide and 4g of 2-acrylamido-2-methylpropanesulfonate into 70g of clear water and stir evenly, then add 0.05g of azobisisobutylamidine hydrochloride, 0.01g of N,N-methylenebis Acrylamide, 0.6g formaldehyde, after it is fully dissolved, add 15g nanocellulose, stir again and put it in a 70℃ oven for 6 hours to form a gel block, granulate the gel block, and crush it into particles with a diameter of 1-1.5mm , to obtain the expanded particles A3 of the present invention.

[0039] Put 20g of 1mm pumice balls into a glass bottle, and place in a thermostat to preheat to 110°C; add 2.5g of epoxy resin powder to the preheated pumice balls, and mix well; put the mixture into a 150°C oven to heat, Take it out and mix once every 20 minutes, take it out after 2 hours for cooling, and separate to obtain curable particles B3 of the present invention.

[0040] Use p-toluenesulfonic acid as the curing agent C3 of the present invention.

[0041] Store A3, B3, and C3 separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com