Swelling particle heterogeneous crack plugging effect improver and preparation method thereof

A body-expanding granule and heterogeneous technology, applied in the field of volume-expanding granule non-homogeneous crack plugging effect improver and preparation field, to achieve the effect of breakthrough pressure gradient increase and plugging effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

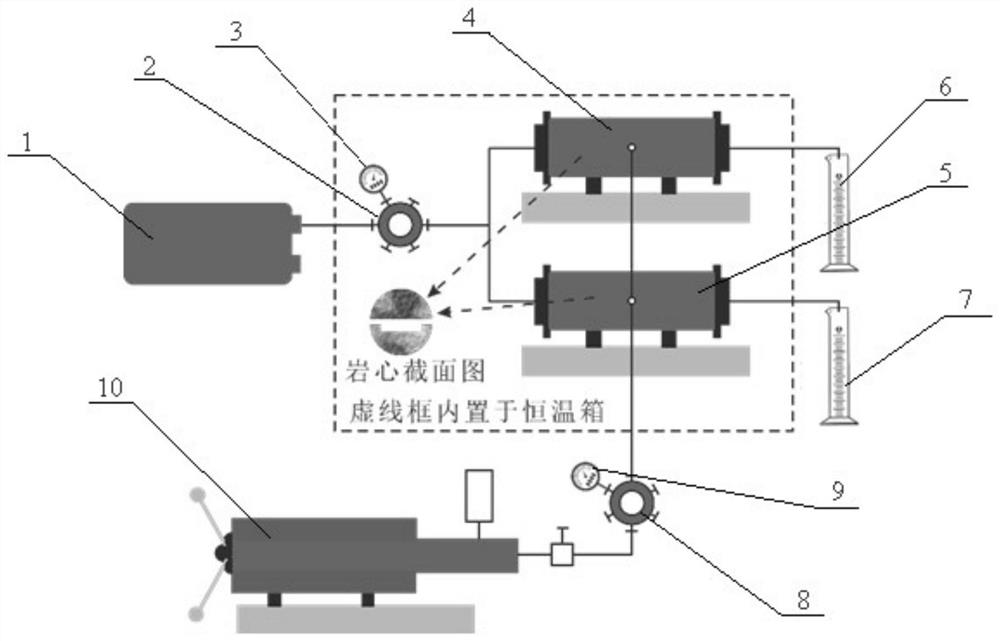

Method used

Image

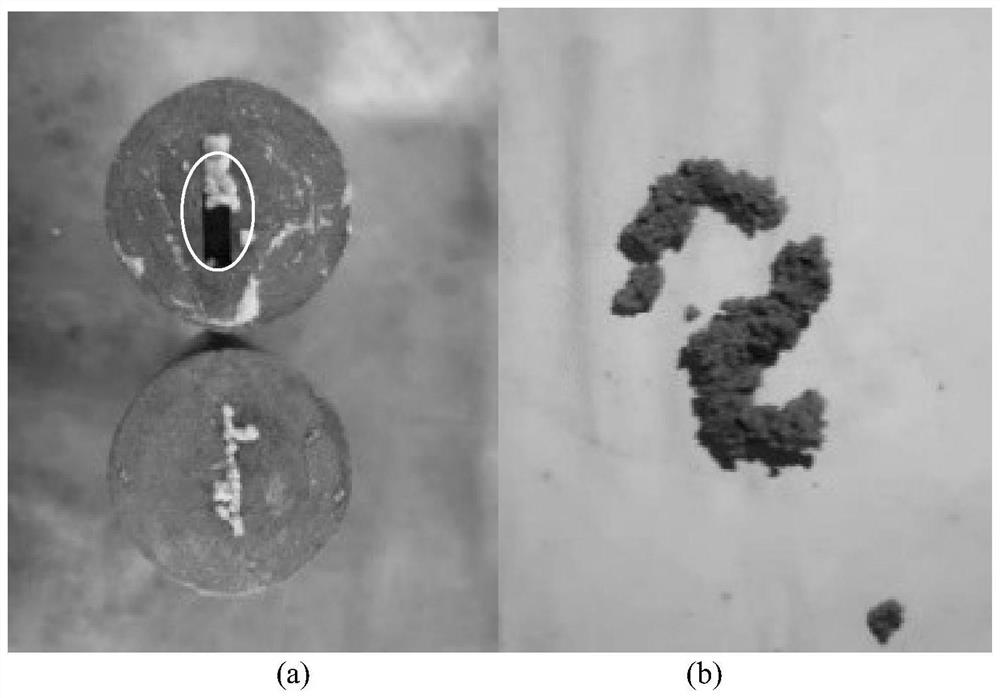

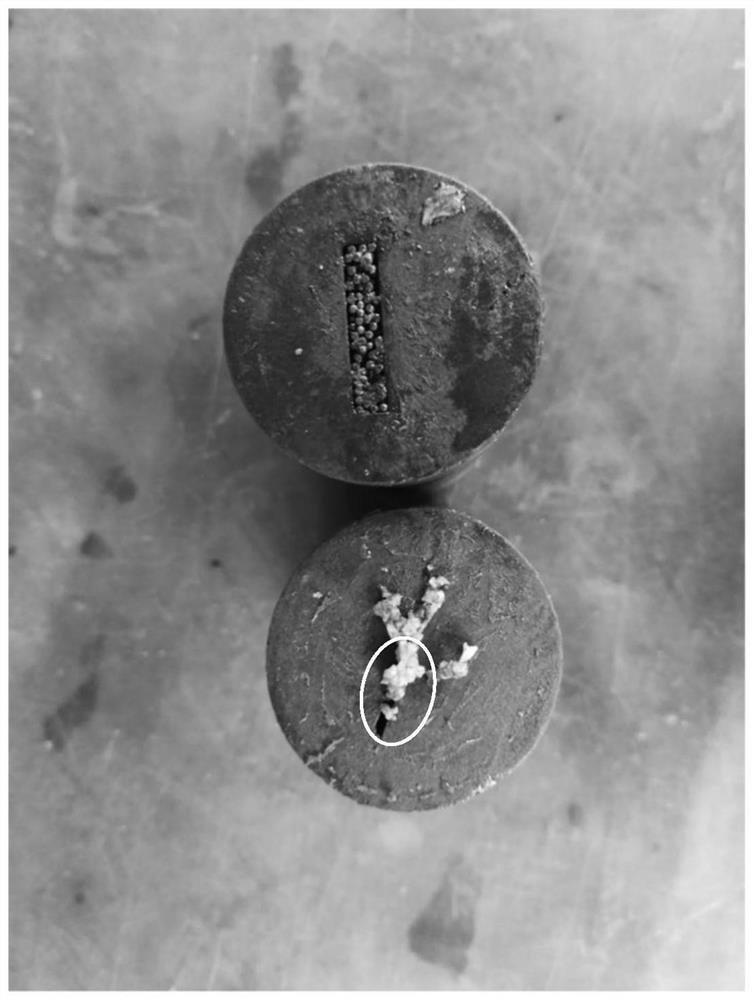

Examples

preparation example Construction

[0033] A preparation method of a volume-expanding particle heterogeneous crack plugging effect improving agent, comprising the following steps:

[0034] Step 1: Prepare coupling agent modified matrix particles;

[0035] Step 2: Grinding the coating resin into powder and preheating, while preheating the coupling agent modified matrix particles obtained in step 1;

[0036] Step 3: Mix the lubricant, the coating resin in step 2, and the modified matrix particles of the coupling agent evenly, and heat at 120-180°C; take out the mixture every t time during the heating process, stir evenly and continue heating , After 0.5-1h, the desired modifier can be obtained.

[0037] The preparation process of the coupling agent modified matrix particles in step 1 is as follows:

[0038] S11: Mix the coupling agent, water and alcohol evenly under the condition of pH = 4-9, and react for 1-2 hours to obtain a coupling agent hydrolyzate;

[0039] S12: mix and react the matrix particles and the...

Embodiment 1

[0045] According to the following steps, the volume-expanding particle heterogeneous crack plugging effect improving agent is prepared;

[0046]Step 1: At room temperature, mix 6mL of γ-aminopropyltriethoxysilane, 4ml of water and 40ml of ethanol at pH = 9.0 and react for 2 hours to obtain a coupling agent hydrolyzate; 50g of The volcanic stone balls and 25g coupling agent hydrolyzate were mixed and reacted at room temperature for 2 hours; then the volcanic stone balls were filtered and placed in an oven at 60°C for 5 hours to obtain the coupling agent modified matrix particles.

[0047] Step 2: Grind 15g of terpene phenolic resin into powder and preheat at 40°C for 10min, meanwhile preheat 84.6g of coupling agent-modified matrix particles at 130°C for 10min.

[0048] Step 3: Mix the preheated terpene phenolic resin powder, coupling agent modified matrix particles and 0.4g calcium stearate evenly, and place in a constant temperature oven at 170°C for heating; remove the mixtur...

Embodiment 2

[0062] According to the following steps, the volume-expanding particle heterogeneous crack plugging effect improver is prepared:

[0063] Step 1: At room temperature, mix 5mL of γ-(2,3-glycidoxy)propyltrimethoxysilane, 40ml of water and 5ml of methanol at pH = 4.0 and react for 2 hours to obtain the hydrolyzed coupling agent solution; 50g of medical stone balls with an average particle size of 1mm and 20g of coupling agent hydrolyzate were mixed and reacted for 2h at room temperature; then the medical stone balls were filtered and dried in an oven at 60°C for 5h to obtain the coupling agent Linking agent modified matrix particles.

[0064] Step 2: Grind 10 g of solid epoxy resin into powder and preheat at 40° C. for 10 minutes, and at the same time preheat 89.5 g of coupling agent-modified matrix particles at 100° C. for 10 minutes.

[0065] Step 3: Mix the preheated solid epoxy resin powder, coupling agent modified matrix particles and 0.5g calcium stearate evenly, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com