Garment treatment method and garment treatment equipment

A technology of clothes processing and equipment, which is applied to the control devices of washing machines, textiles and papermaking, household appliances, etc., and can solve problems such as unavoidable, color fading, and non-existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

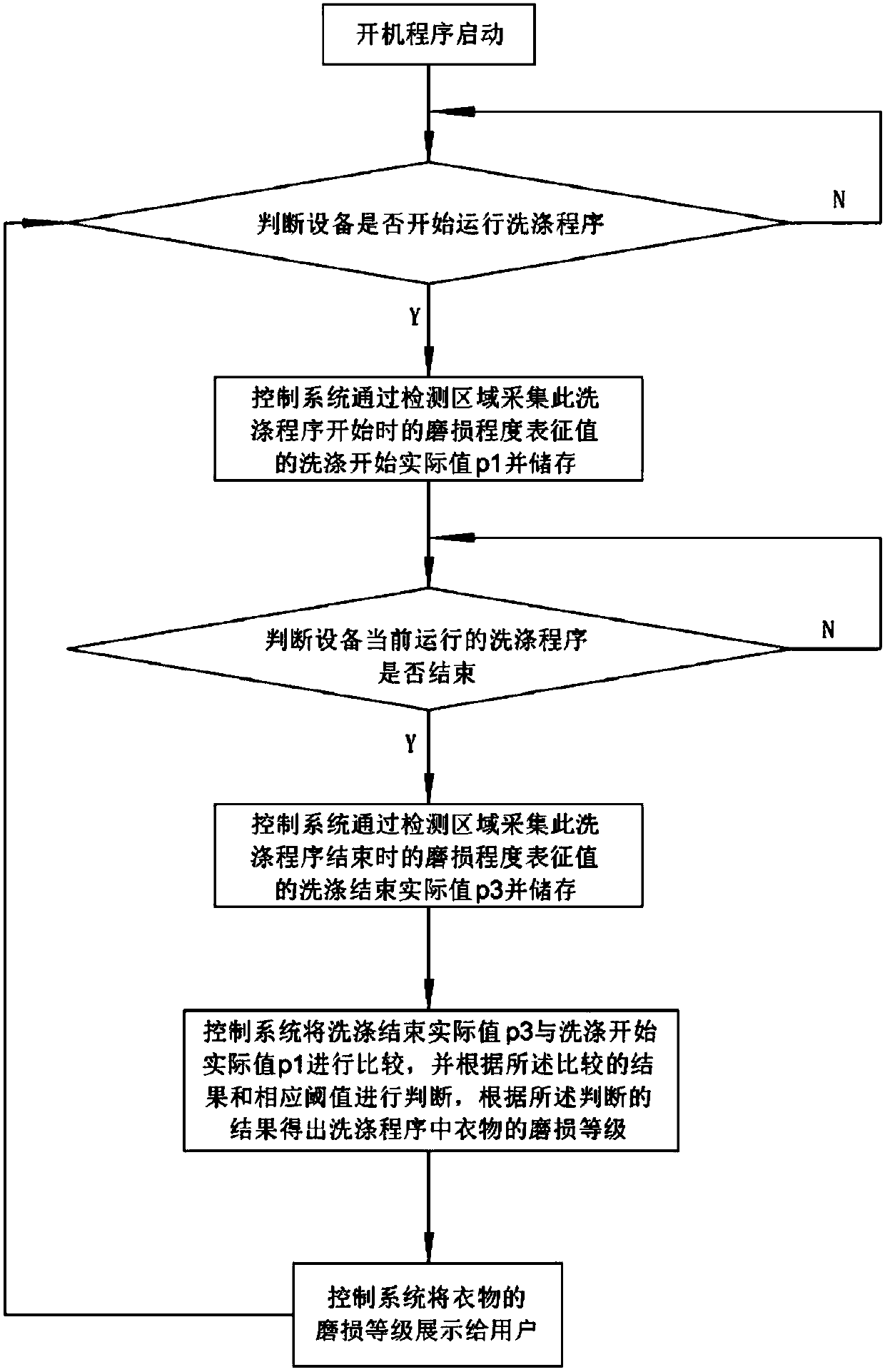

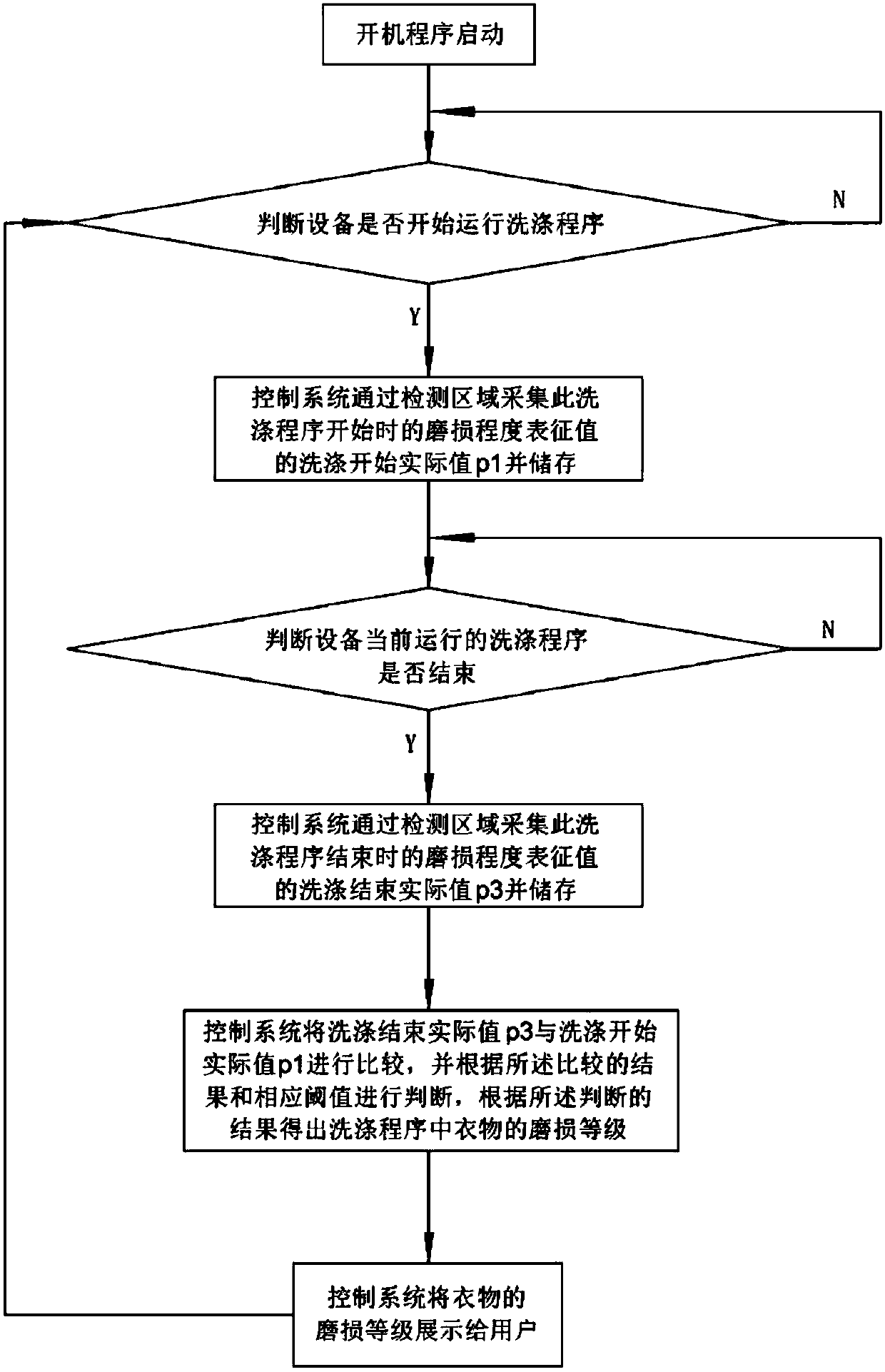

[0088] Such as figure 1 As shown, the clothing wear degree detection method in the present embodiment includes steps:

[0089] S1, start the boot program;

[0090] S2. The control system monitors the operating status of the equipment in real time to determine whether the equipment starts to run the washing program; if so, the control system obtains the actual washing start value p1 of the wear degree representative value at the beginning of the washing program through the data collected in the detection area and stores it. And execute step S3; if not, execute step S5;

[0091] S3. The control system monitors the operating status of the equipment in real time, and judges whether the washing program currently running by the equipment is over; if so, the control system obtains the actual washing end value p3 of the wear degree representative value at the end of the washing program through the data collected in the detection area and Store; execute step S4; if not, execute step ...

Embodiment 2

[0104] The difference between the clothes processing method in this embodiment and the above-mentioned embodiments is: the lint content level is preset in the control system; the clothes processing method includes a lint cleaning reminder method; the control system mainly uses the lint cleaning reminder The method obtains the data collected in the detection area after the equipment is turned on, and then obtains the initial actual value of the characteristic value of the lint content, and mainly judges whether it is necessary to perform lint cleaning according to the initial actual value of the characterization value of the lint content; the control system according to the The initial actual value of the lint content characterization value divides the lint content levels and prompts the user.

[0105] Through the clothes processing method introduced in the present invention, the control system can obtain the amount of lint accumulation inside the equipment, and the control syst...

Embodiment 3

[0112] The difference between the laundry processing method in this embodiment and the above-mentioned embodiments is that: the laundry processing method includes a lint cleaning and reminding method; the control system mainly uses the lint cleaning and reminding method to obtain and detect after the device completes all programs instructed by the user. The data collected in the area further obtains the final actual value of the characteristic value of the lint content, and judges whether the lint cleaning is required mainly based on the actual value of the final characterization value of the lint content.

[0113] Through the clothes processing method introduced in the present invention, the control system can obtain the amount of lint accumulation inside the equipment, and the control system divides the amount of lint accumulation into different levels, prompting the user to clean up, so as to avoid affecting the effect of lint collection in subsequent procedures; Chip cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com