Dynamic sealing structure for high-temperature kiln

A dynamic sealing, high temperature furnace technology, used in engine sealing, engine components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

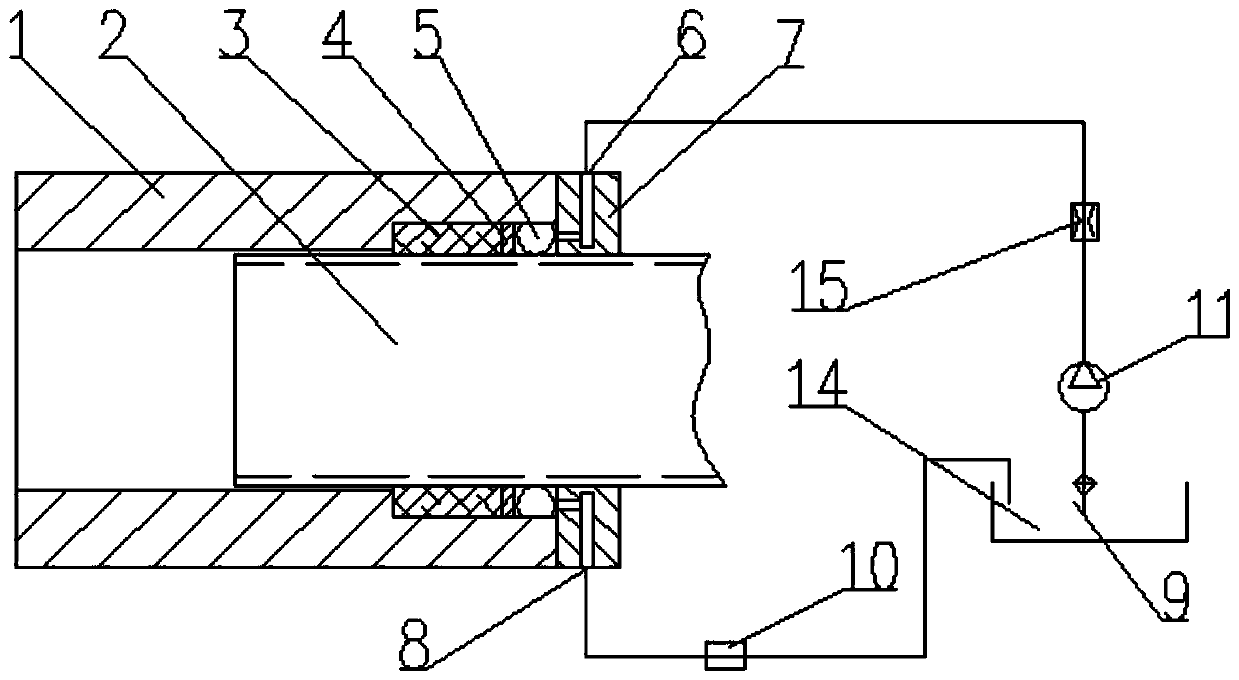

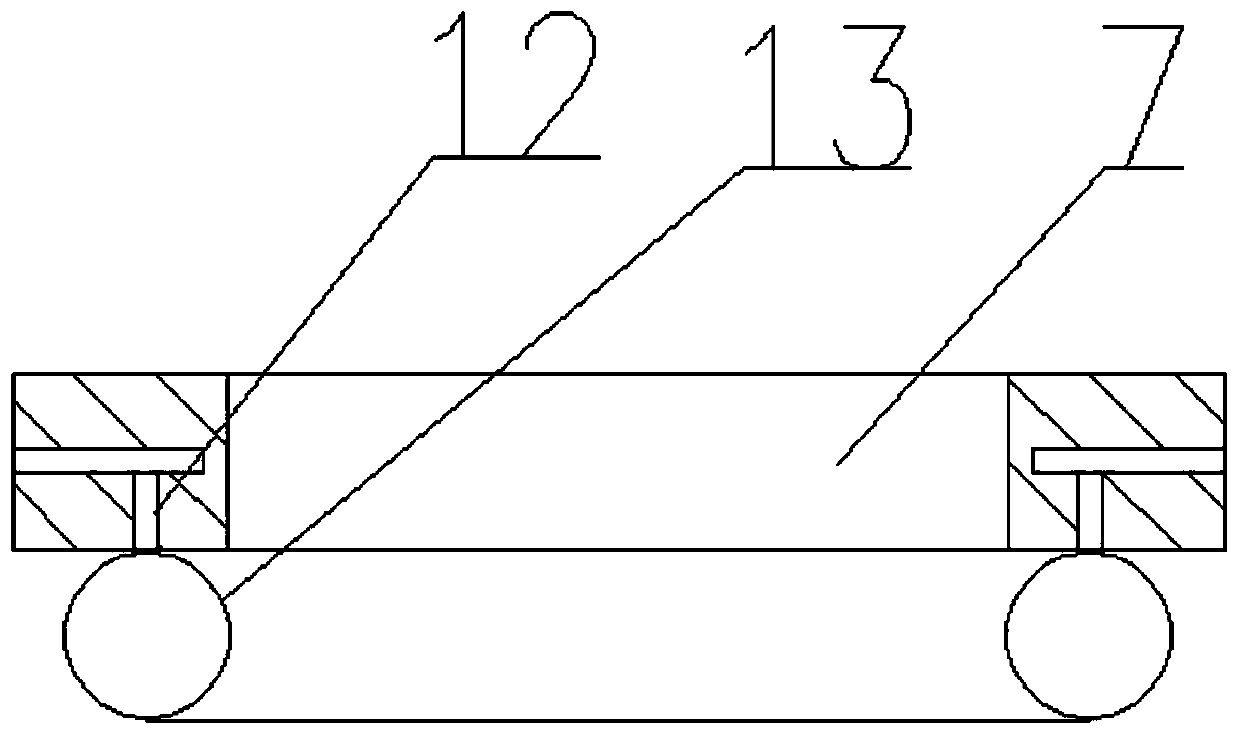

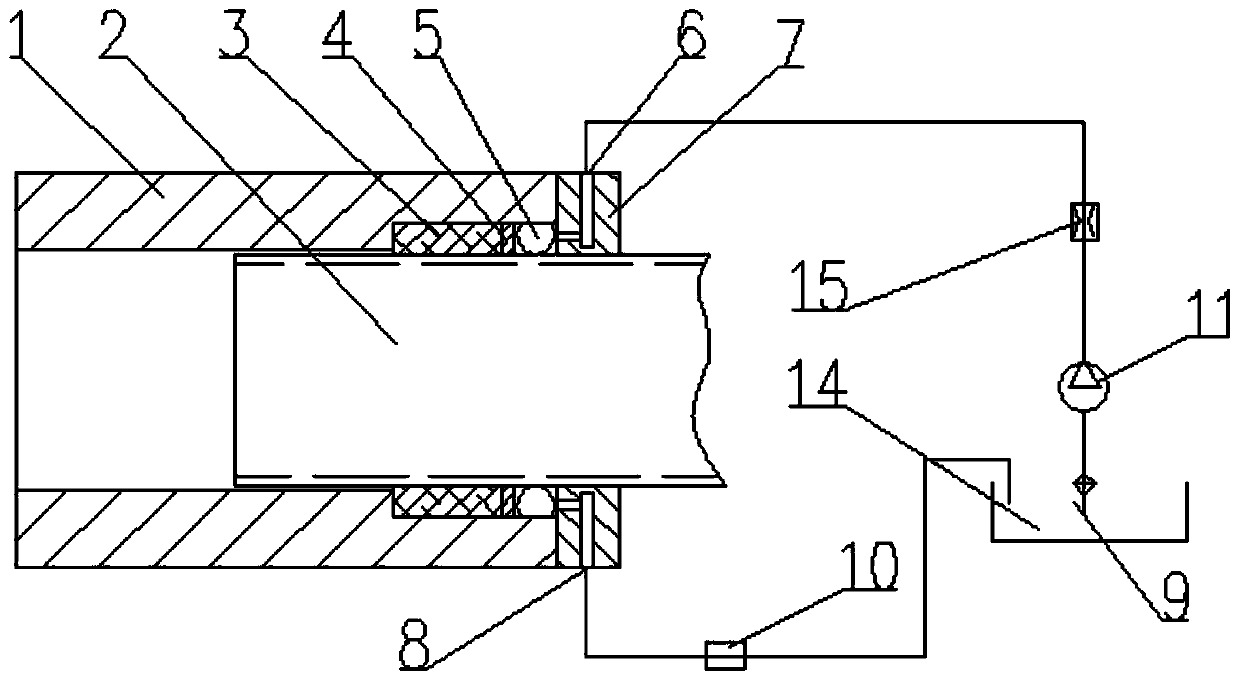

[0012] A dynamic sealing structure for a high-temperature furnace. The structure is composed of a static fixing part, a dynamic rotating part, a sealing packing, a compression retaining ring, a pressurized elastic bag and a cooling pressure pump station. The static fixing part and the dynamic rotating part The connection part is provided with a sealing packing, a compression retaining ring and a pressurized elastic bag in sequence. The pressurized elastic bag is inlaid and fixed on the sealing cover, and the sealing cover is fixed on the static fixture by screws. The liquid inlet and the The liquid outlet is connected to the cooling pressure pump station through a pipeline. A back pressure valve is set on the pipeline of the liquid outlet, and a flow valve is set on the pipeline of the liquid inlet. By adjusting the back pressure valve and the flow valve, the pressure and flow can be realized. Adjustment.

[0013] Referring to the accompanying drawings, the present invention p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com