Heat-resistant steel material residual life evaluation method

A technology for life evaluation and heat-resistant steel, applied in the field of heat-resistant steel materials, can solve the problems of insufficient detection reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

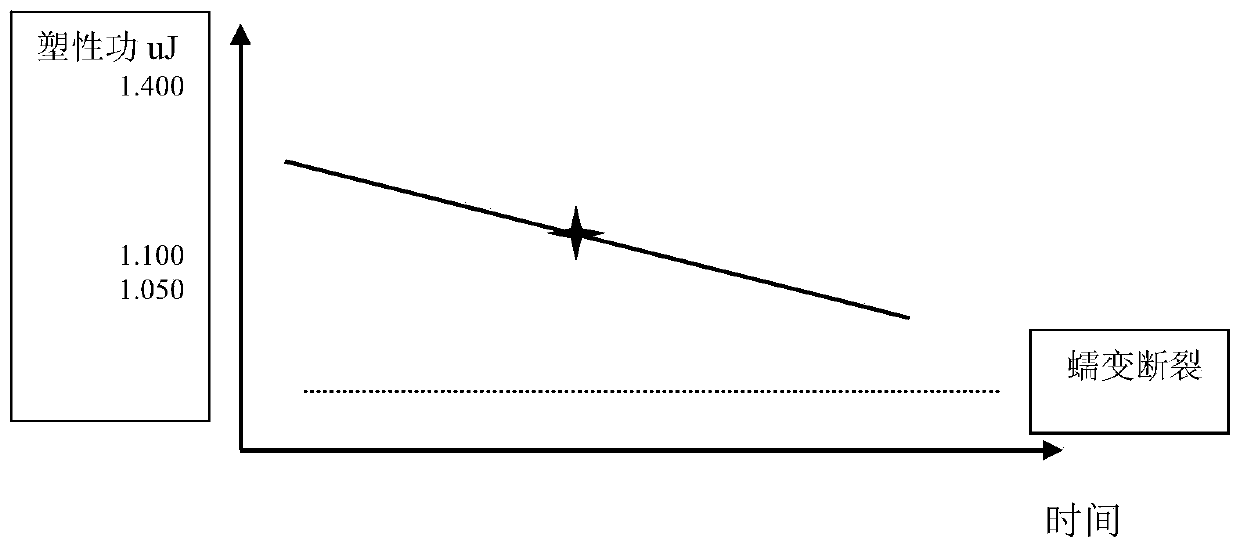

[0026] The samples were selected from the superheater of a 1000MW ultra-supercritical generator in a power plant, and the material was austenitic heat-resistant steel HR3C. The samples were taken to prepare a series of creep samples, respectively at 700°C and 0.5R p0.2 Tested under the conditions of 1000h, 2000h, 3000h, 4000h to the creep rupture of the sample, using the indentation method (1000mN) to test the indentation plastic work of the above samples respectively 1.335uJ, 1.255uJ, 1.185uJ, 1.105uJ, 1.050uJ , to establish the corresponding trend relationship between material life and plastic work: plastic work=1.405-0.000075*life (time), see figure 1 . The measured plastic work of the tested sample is 1.260uJ, figure 1 middle The position represents the remaining life of the sample, and the calculated remaining life is 2800h.

Embodiment 2

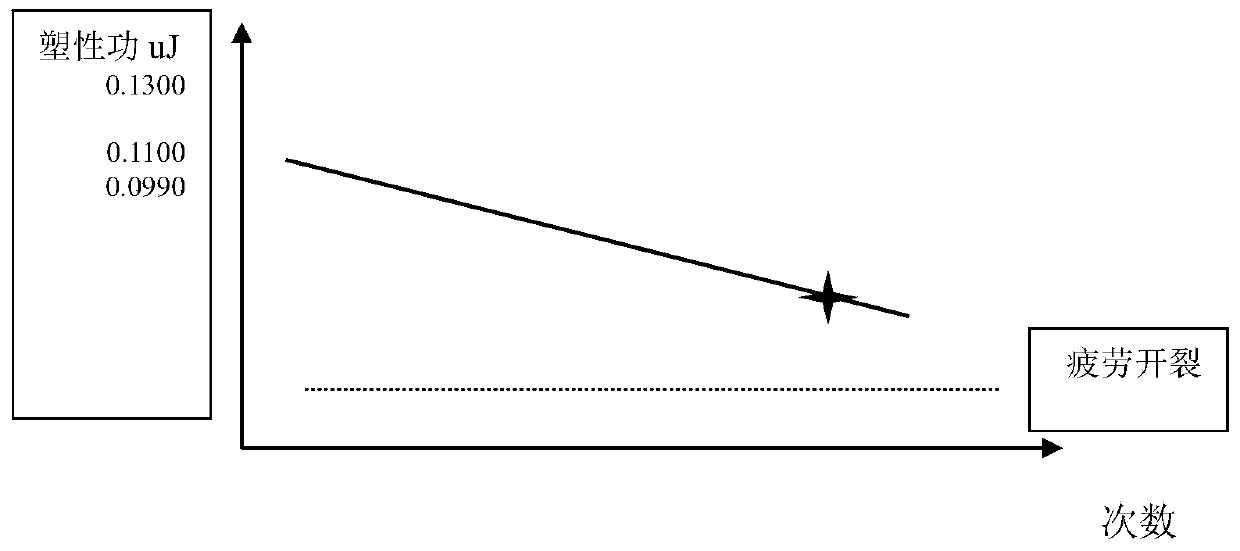

[0028] The samples are selected from the main steam valve of a gas turbine power plant, and the material is P91. Due to the large fluctuations in the operating temperature of the long-term peak-shaving unit, the life of the main steam valve's resistance to cold and heat fatigue is predicted. 200, 400, 600, 800 cycles at 550°C-100°C and fatigue cracking samples were tested by indentation method (300mN) respectively. The indentation plastic work of the above samples was 0.1240uJ, 0.1183uJ, 0.1135uJ respectively , 0.1055uJ, 0.0990uJ, establish the corresponding trend relationship between material life and plastic work, see figure 2 , plastic work=0.1311-0.000032*life (times).

[0029] Measure the plastic work of the tested sample to be 0.1110uJ, figure 2 middle The position represents the remaining life of the sample, and the calculated remaining life is 375 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com