Roof insulator suitable for high-speed electric locomotive

An insulation technology for electric locomotives and car roofs, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of dirty flashover of insulators, tearing of sheds, etc., to improve flashover voltage, ensure insulation performance, and increase creepage distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

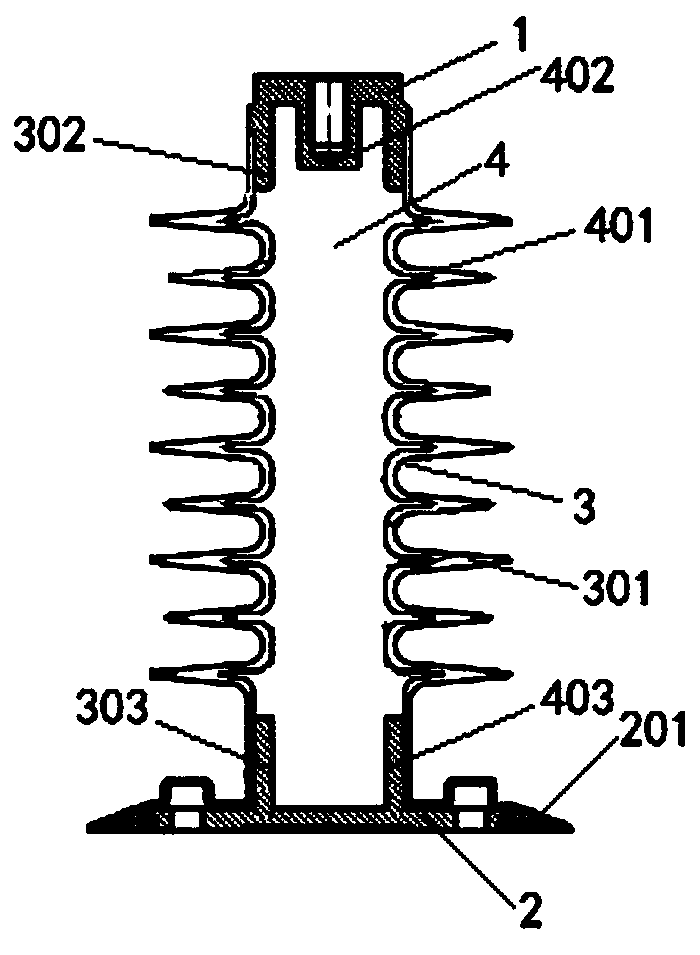

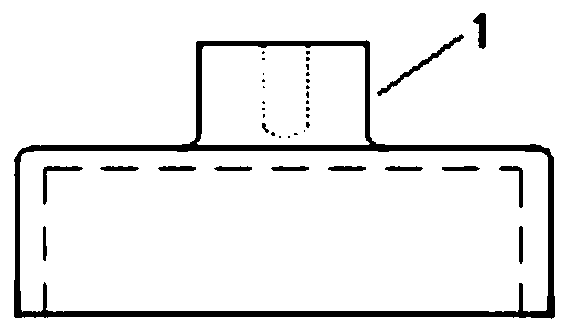

[0026] Embodiment 1: as Figure 1-7As shown, the roof insulator suitable for high-speed electric locomotives includes upper fittings 1, lower fittings 2, outer casing 3 and mandrel 4. The outer casing 3 includes several sheds 301, and several said sheds 301 are along the The axial direction of the mandrel 4 is arranged on the side wall of the mandrel 4 around the mandrel 4, the upper end of the mandrel 4 is connected with the upper metal tool 1, and the mandrel 4 The lower end of the lower metal fitting 2 is connected, and the mandrel 4 is a mandrel with a skeleton structure; the skeleton structure surrounds the outer wall of the mandrel 4 and is perpendicular to the axial direction of the mandrel 4 The number of support teeth 401 is formed in a one-to-one correspondence with the number of the sheds 301; the support teeth 401 protrude outward along the radial direction of the mandrel 4 On the side wall of the mandrel 4; each of the support teeth 401 is along the radial direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com