Electrical connection structure of pluggable battery cabinet

An electrical connection structure, plug-in technology, applied in the direction of conductive connection, structural parts, battery pack parts, etc., can solve the problems of high maintenance cost, difficult to remove and replace the battery and maintenance, battery cabinet can not work, etc., to ensure Effect of Mating Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

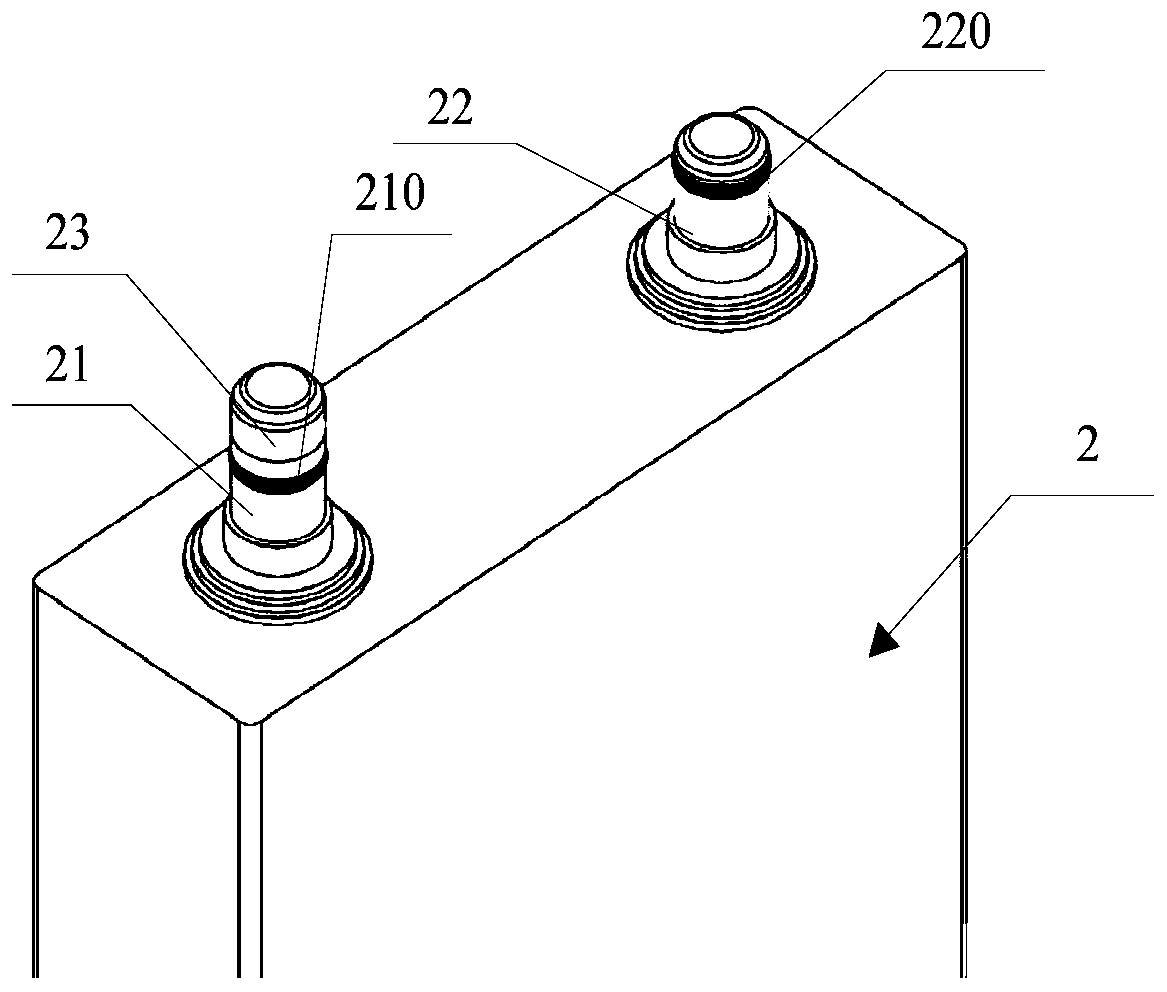

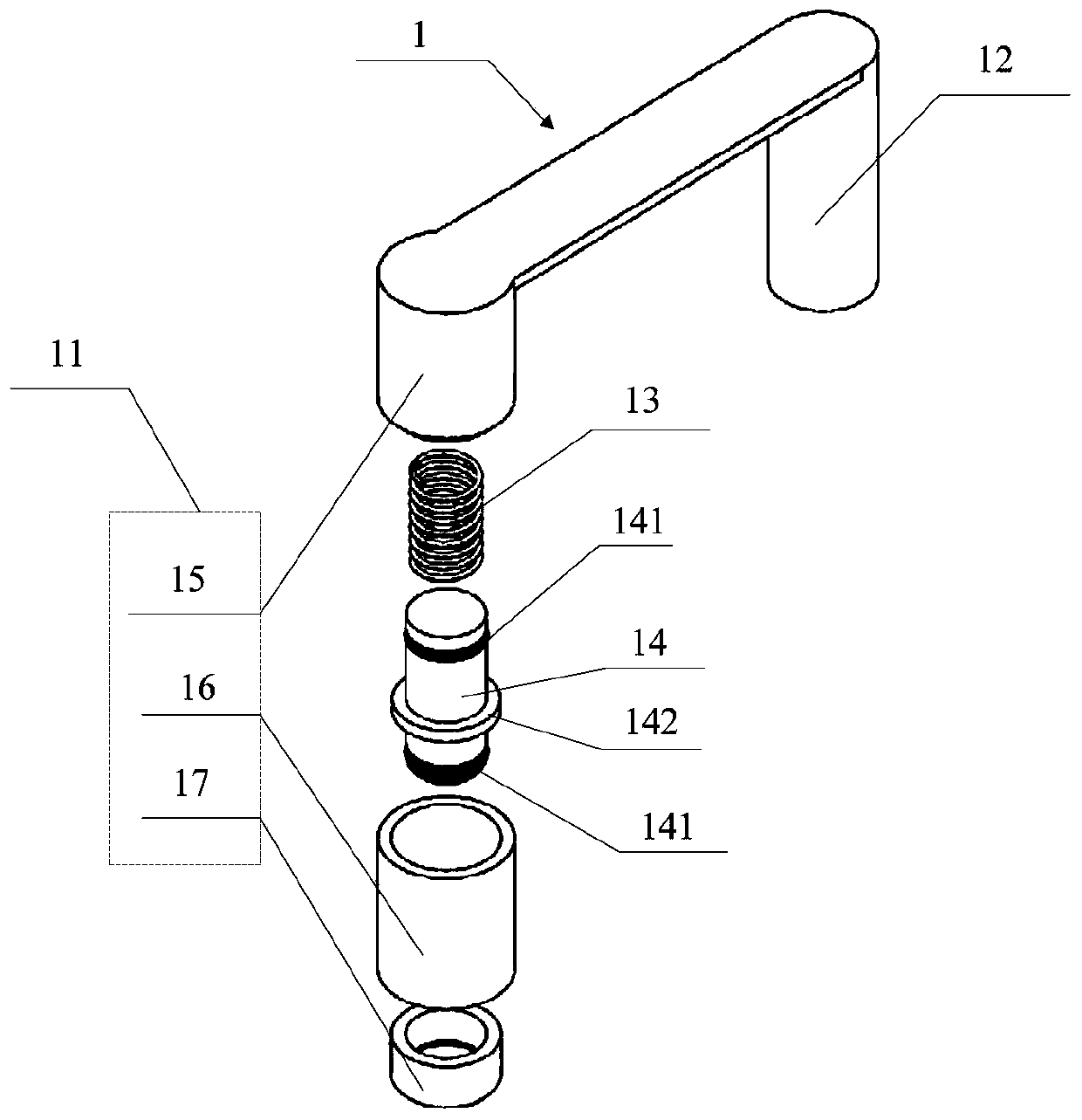

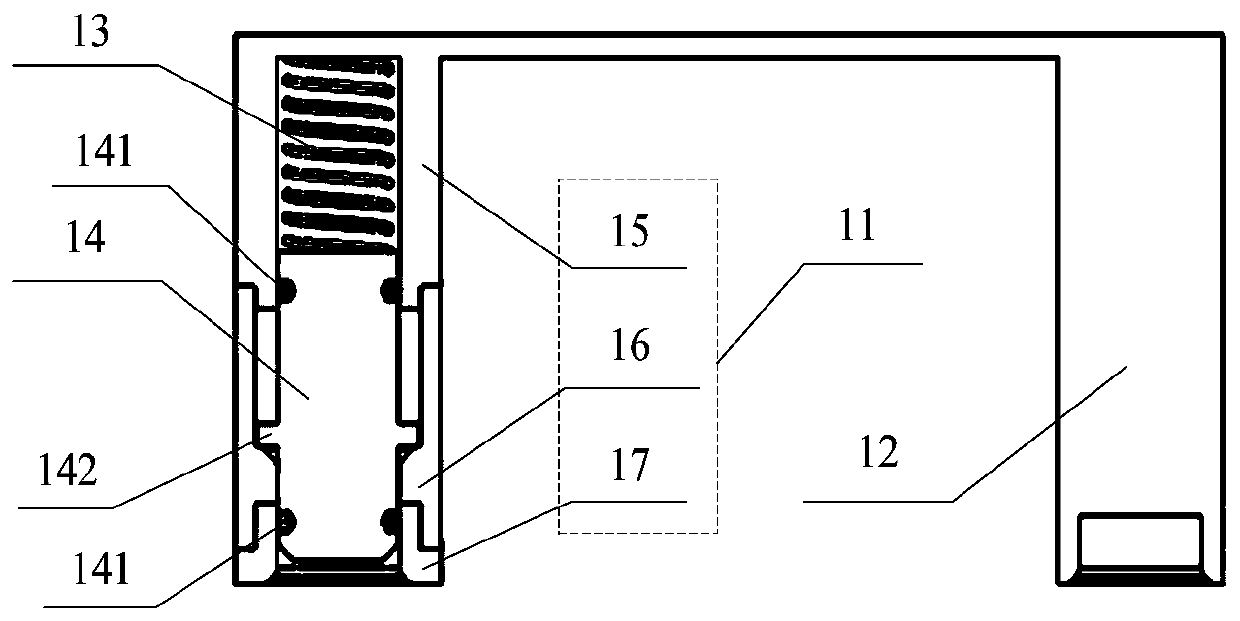

[0018] This application discloses an electrical connection structure of a plug-in battery cabinet, please refer to Figure 1-3 , the electrical connection structure includes N anti-short-circuit structural parts 1 and N single-cell batteries 2, each single-cell battery 2 corresponds to one anti-short-circuit structural part 1, and the N short-circuit-proof structural parts 1 are installed on the plug-in battery In the cabinet, the single battery 2 is pluggably installed in the plug-in battery cabinet.

[0019] Please refer to figure 1 , each single cell 2 includes a first pole 21 and a second pole 22, one of the first pole 21 and the second pole 22 is a positive pole, the other is a negative pole, and the first pole 21 is fixed There is a canted coil spring 210 , the canted coil spring 220 is fixed on the second pole 22 , and the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com