Bottle washing device for plant tissue culture bottles

A technology for plant tissue culture and culture bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning of solid medium and other wastes, facilitate repeated use, and increase the cleaning area , Improve the effect of cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] Referring to the accompanying drawings, the specific implementation is as follows:

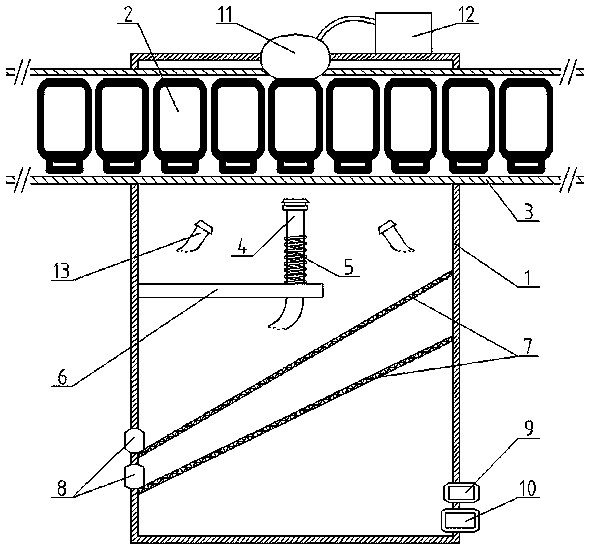

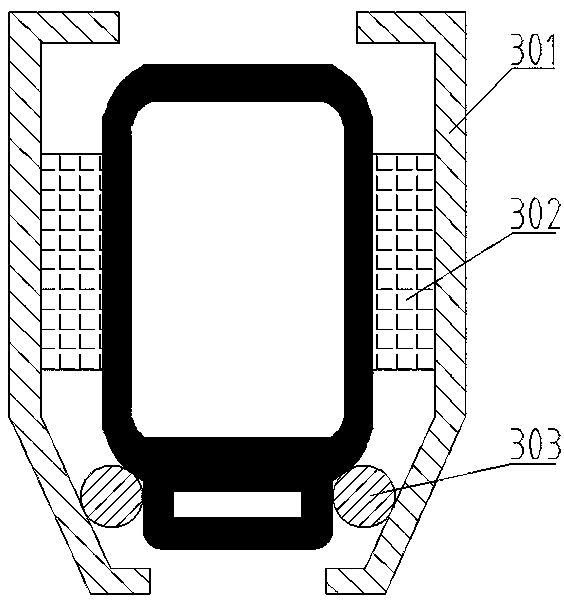

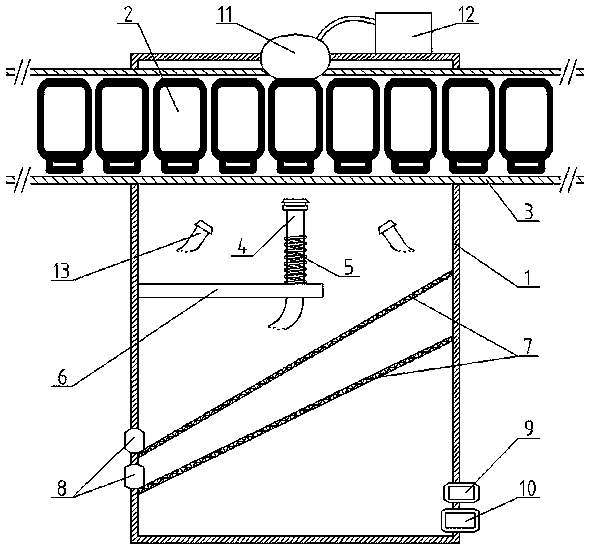

[0025] A bottle washing device for plant tissue culture bottles, comprising a case body 1 and a transfer device 3 for transferring upside-down culture bottles 2, the transfer device 3 is arranged through the case body 1 and is located near the top inner wall of the case body 1 The conveying device 3 can clamp the vertically inverted culture bottle 2 from both sides of its conveying direction, and can make the bottle bottom and bottle mouth of the culture bottle 2 expose from the upper and lower sides of the conveying device 3 respectively, and the conveying device 3 includes two sections of horizontal and opposite delivery tracks 301, so as to clamp the culture bottle 2 from both sides in the horizontal direction of the culture bottle 2. The conveyor belts 302 on both sides cooperate to drive the culture bottle 2 to move horizontally, and the transmission track 301 is provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com