Casting factory double-disc cooler water adding device

A technology for cooling machines and foundries, which is applied to casting molding equipment, cleaning/processing machinery for casting mold materials, manufacturing tools, etc. It can solve the problem of loose installation of wear plates and buffer plates, poor filtering ability, and damage to buffer plates and other problems, to achieve the effect of convenient and effective cleaning, easy installation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

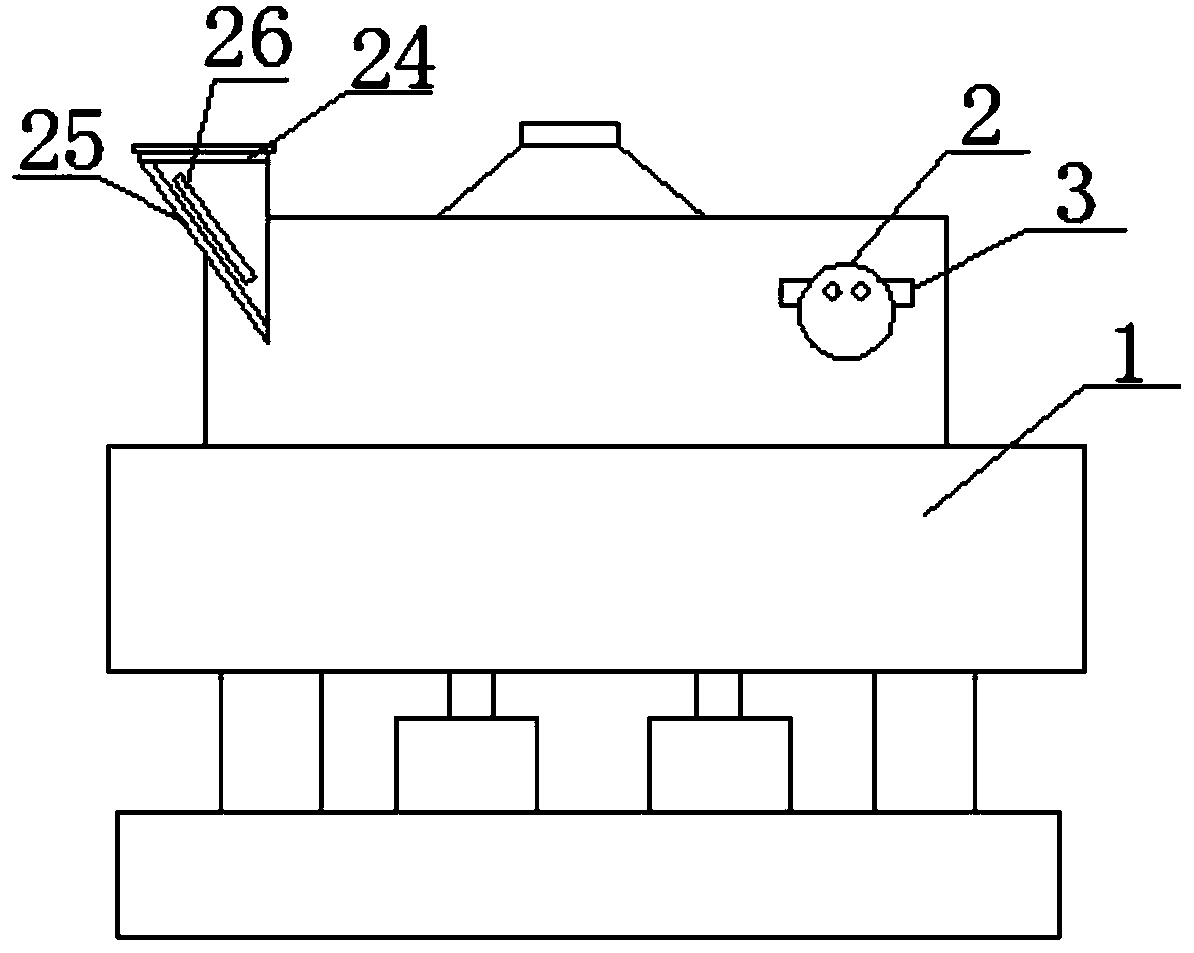

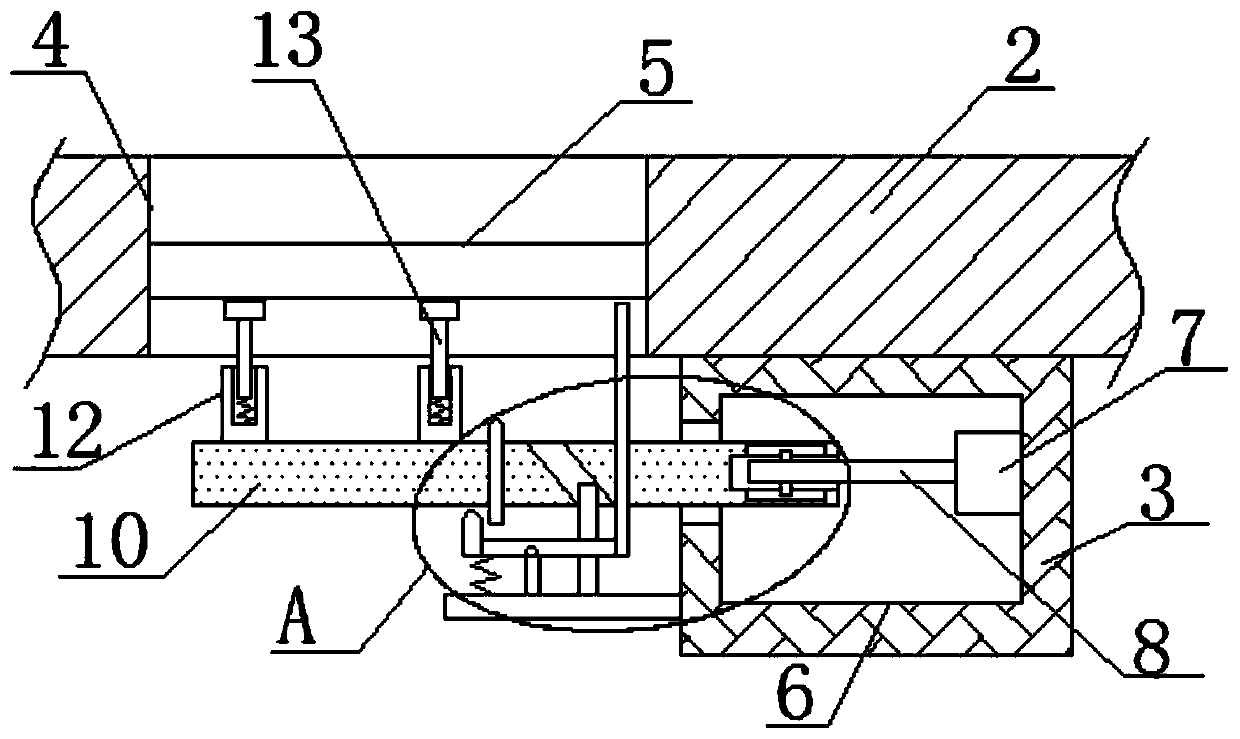

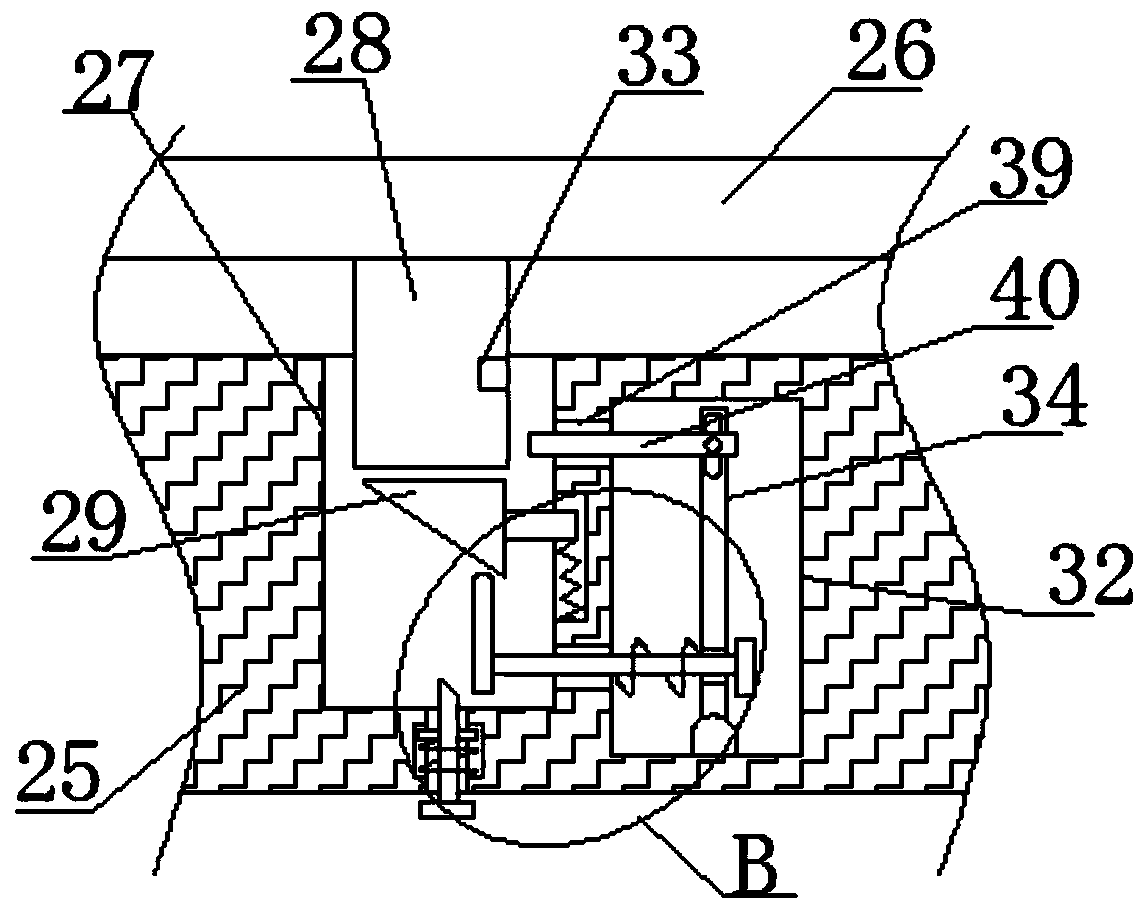

[0024] refer to Figure 1-5 , a water adding device for a double-disk cooler in a foundry, comprising a double-disc cooler 1, a respirator 2 is provided on the double-disc cooler 1, a support column 3 is provided on one side of the respirator 2, and a support column 3 is provided on one side of the respirator 2 There is a vent hole 4, a filter plate 5 is movably installed in the vent hole 4, a placement cavity 6 is opened on the support column 3, a motor 7 is fixedly installed on the inner wall of one side of the placement cavity 6, and the output shaft of the motor 7 is fixed by a coupling A rotating shaft 8 is installed, and a rotating ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap