An adjustable mold handling device

A technology for handling equipment and molds, which is applied in the field of adjustable mold handling equipment, can solve the problems of large occupied space, reduced work efficiency, reasonable arrangement, etc., and achieves the effect of simple structure and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

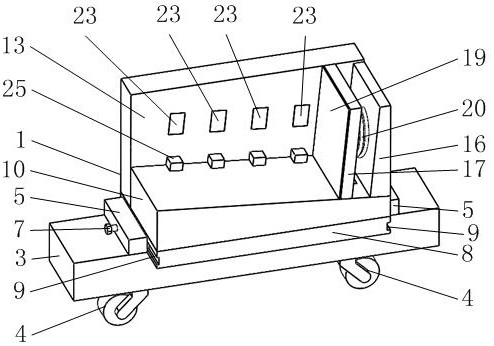

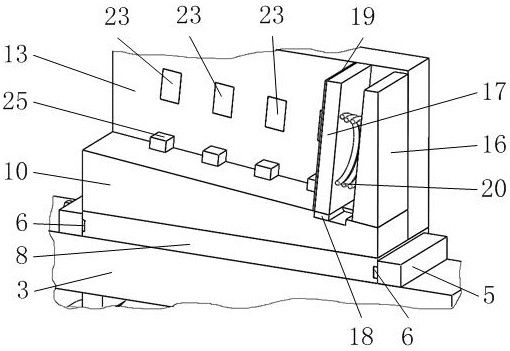

[0030] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

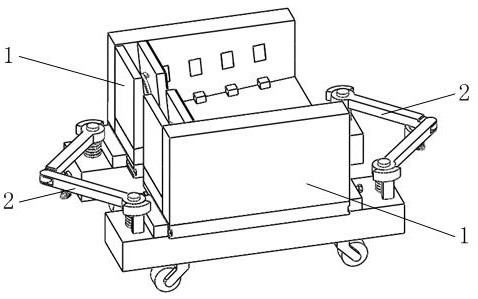

[0031] Such as figure 1 As shown, it includes a support mechanism 1 and an adjustment mechanism 2, wherein the same side of the two symmetrically distributed support mechanisms 1 are respectively connected by the adjustment mechanism 2, and the two symmetrically distributed adjustment mechanisms 2 are used to synchronously adjust the two support mechanisms 1 spacing.

[0032] Such as figure 2 As shown, the above-mentioned support mechanism 1 includes a base 3, a universal wheel 4, a guide rail 5, a bolt 7, a sliding seat 8, a support block 10, a vertical plate 13, a baffle plate 16, a buffer plate 17, a rubber pad A19, a spring A20, a U Model plate 21, clamping plate 22, spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com