Wet concrete feeding assistant stirrer and using method thereof

A concrete and agitator technology, applied in the field of wet concrete recycling system machinery, can solve the problems of slurry leakage, unsolved sealing, poor use of screening machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

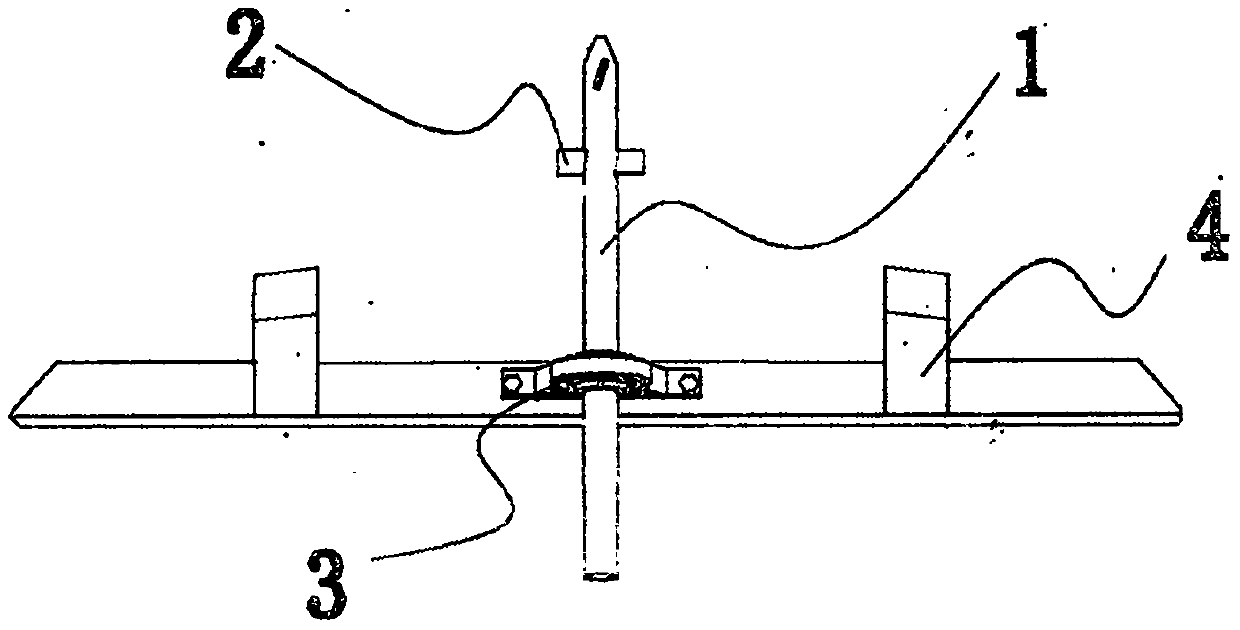

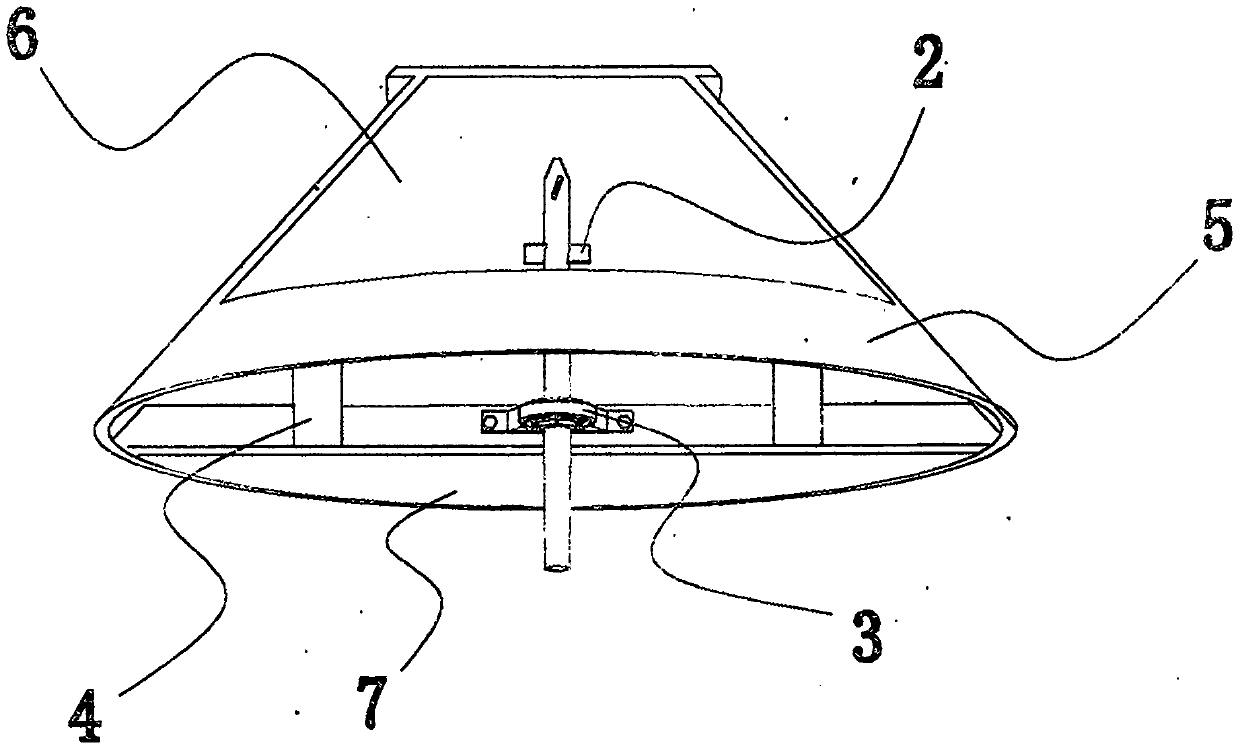

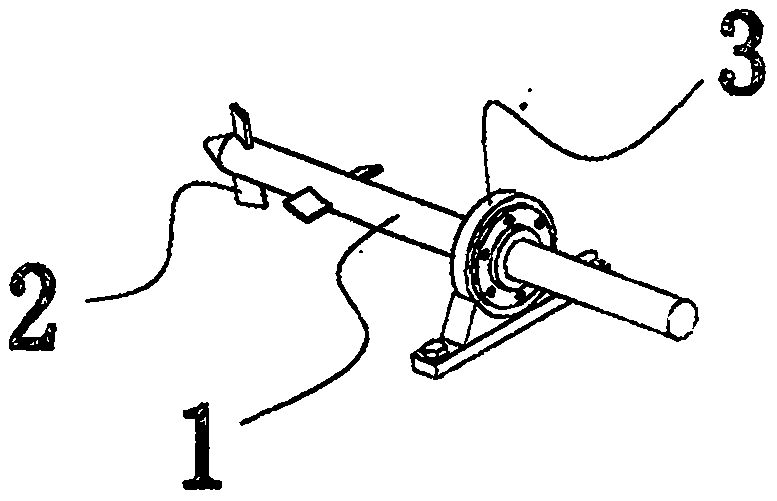

[0029] Feed assist mixer for wet concrete and method of use thereof, such as Figure 1-Figure 6 As shown, it includes a stirring shaft 1, a stirring blade 2, a bearing and a bearing seat 3, a bearing seat mounting frame 4, a feed trough 5, a feed port 6, and a discharge port 7. It is characterized in that: there are multiple sets of stirring blades 2, and the stirring blades 2 are installed on the stirring shaft 1 with a width and a height of about 10mm, and the stirring shaft 1 is installed on the bearing seat mounting frame 4 through the bearing and the bearing seat 3, Bearing seat mounting frame 4 is installed in the inside of feeding tank 5, and the top of stirring shaft 1 is directly installed on the bottom above the main shaft of a kind of screening machine.

[0030]The use method of a kind of wet concrete feeding auxiliary mixer and its using method is described, it is characterized in that, step 1; The appearance characteristics of the spiral sewage digging pump of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com