A high-efficiency plugging removal system, preparation method and application of polymer flooding injection well

A technology for injecting wells and polymers, applied in drilling compositions, chemical instruments and methods, and production fluids, etc., can solve problems such as pressure rise, oil well production reduction, and dispensing volume reduction, and achieve wide water salinity. , the effect of fast degradation speed and high degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

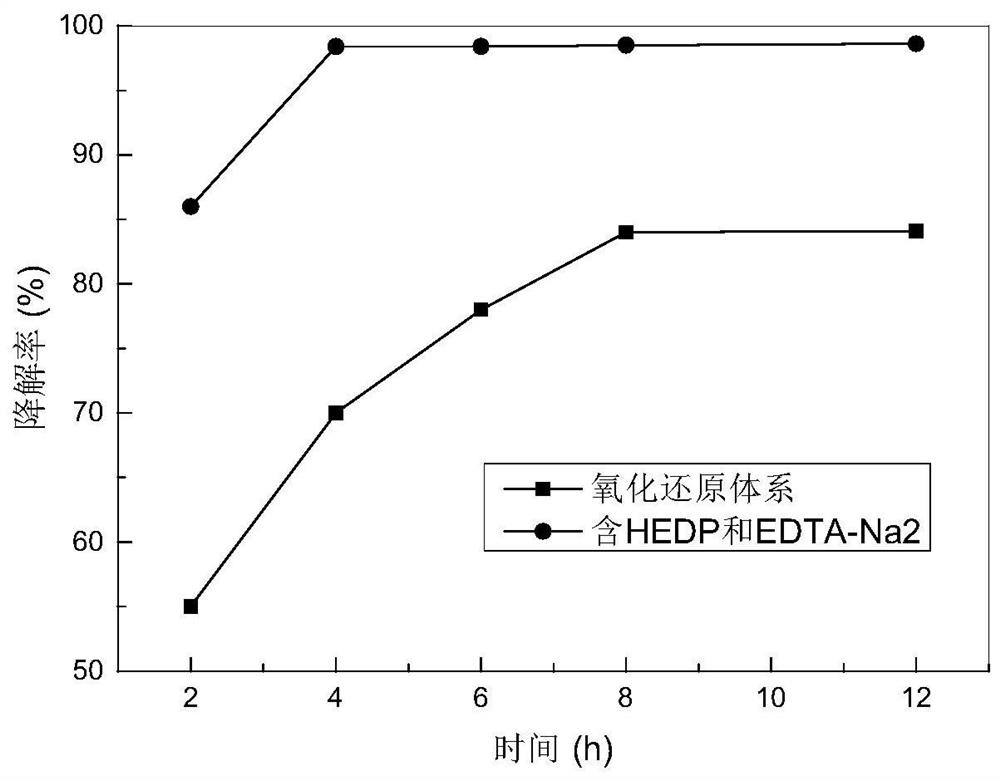

[0023]This embodiment provides a single redox system and a polymer flooding injection well high-efficiency plug-removing system added with a gel group disintegrating agent. A single redox system is 25 parts by mass of sodium bromate and sodium bisulfite (molar ratio is 1:1), and 75 parts by mass of water are added to the container, stirred and mixed evenly, and the redox system used in this case can be obtained. The high-efficiency plug-removing system for polymer flooding injection wells with gel group disintegrating agent is 25 parts by mass of sodium bromate and sodium bisulfite (molar ratio is 1:1), 25 parts by mass of hydroxyethylidene diphosphonic acid and Disodium EDTA (its mass ratio is 7:3) and 50 parts by mass of water are added to the container, stirred and mixed evenly to obtain the polymer flooding injection well high-efficiency plug-removing system used in this example.

[0024] Using 40000mg / L injection water, the single redox system and the polymer flooding inj...

Embodiment 2

[0028] This example provides a high-efficiency plug-removing system for polymer flooding injection wells with gel mass dispersing agents, which are hydroxyethylidene diphosphonic acid (HEDP) and ethylenediaminetetraacetic acid disodium (EDTA-Na) respectively. 2 ), and mixtures of the two.

[0029] 25 parts by mass of sodium bromate and sodium bisulfite (molar ratio is 1:1), 25 parts by mass of hydroxyethylidene diphosphonic acid, and 50 parts by mass of water were added to the container, stirred and mixed to obtain this implementation. For example, the high-efficiency plug removal system (containing HEDP) used in polymer flooding injection wells.

[0030] 25 parts by mass of sodium bromate and sodium bisulfite (molar ratio is 1:1), 25 parts by mass of disodium EDTA, and 50 parts by mass of water were added to the container, stirred and mixed well to obtain this. The high-efficiency plug removal system (EDTA-Na 2 ).

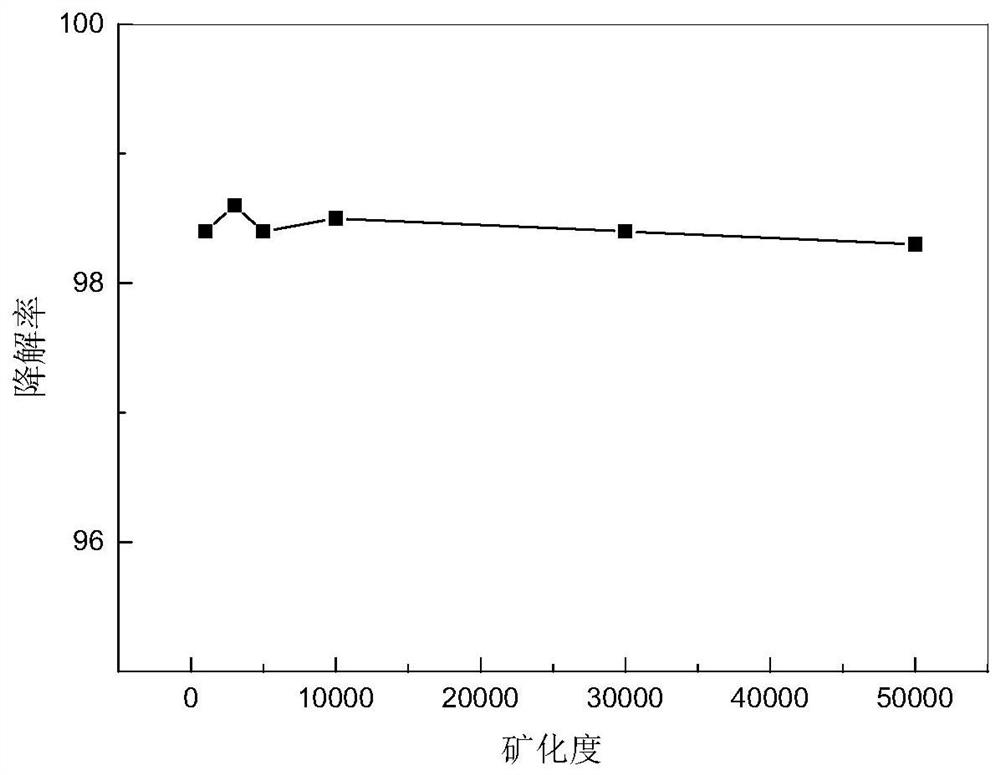

[0031] 25 parts by mass of sodium bromate and sodium bisu...

Embodiment 3

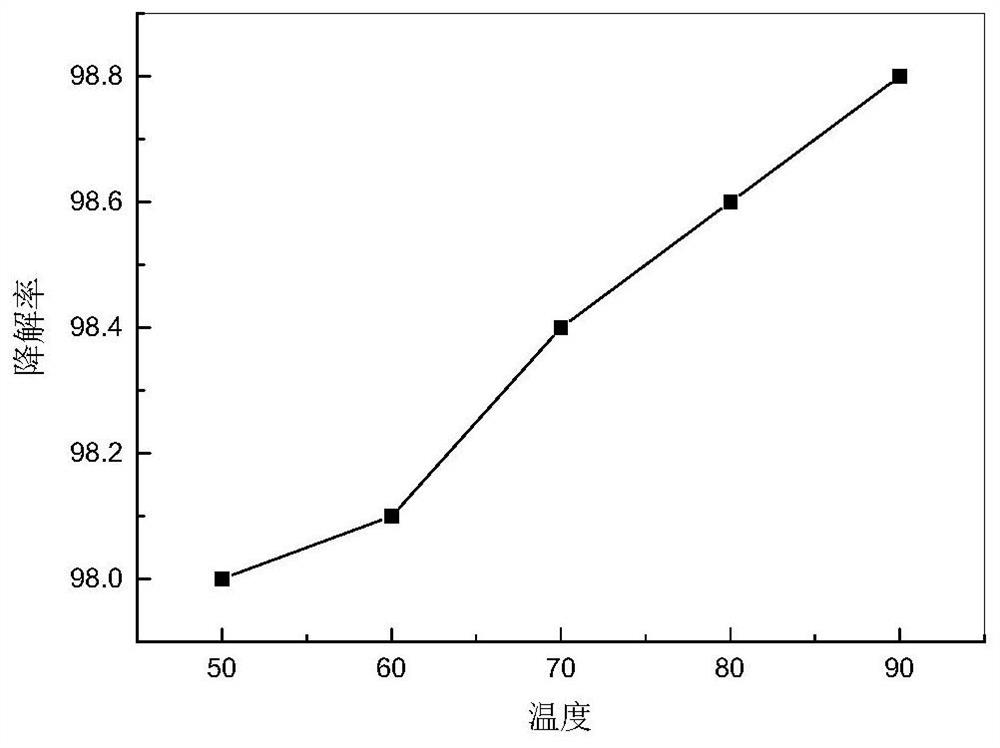

[0035] This case provides a high-efficiency plug removal system for polymer flooding injection wells containing different redox systems, 25 parts by mass of Na 2 S 2 O 8 and FeSO 4 (molar ratio is 1:1), 25 parts by mass of hydroxyethylidene diphosphonic acid and disodium EDTA (its mass ratio is 7:3), 50 parts by mass of water, mix well to obtain the required The high-efficiency plugging removal system for polymer flooding injection wells.

[0036] The difference is to use NaClO 7 and Na 2 S 2 O 3 , H 2 O 2 and FeCl 2 system instead of Na 2 S 2 O 8 and FeSO 4 , and the rest are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com