Thermal composite huff and puff synergistic system for offshore low-yield heavy oil cold production well and operation method

A compound efficiency and thermal compound technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as the limitation of single technology, and achieve the goal of improving mining effect, improving flow capacity and improving production level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

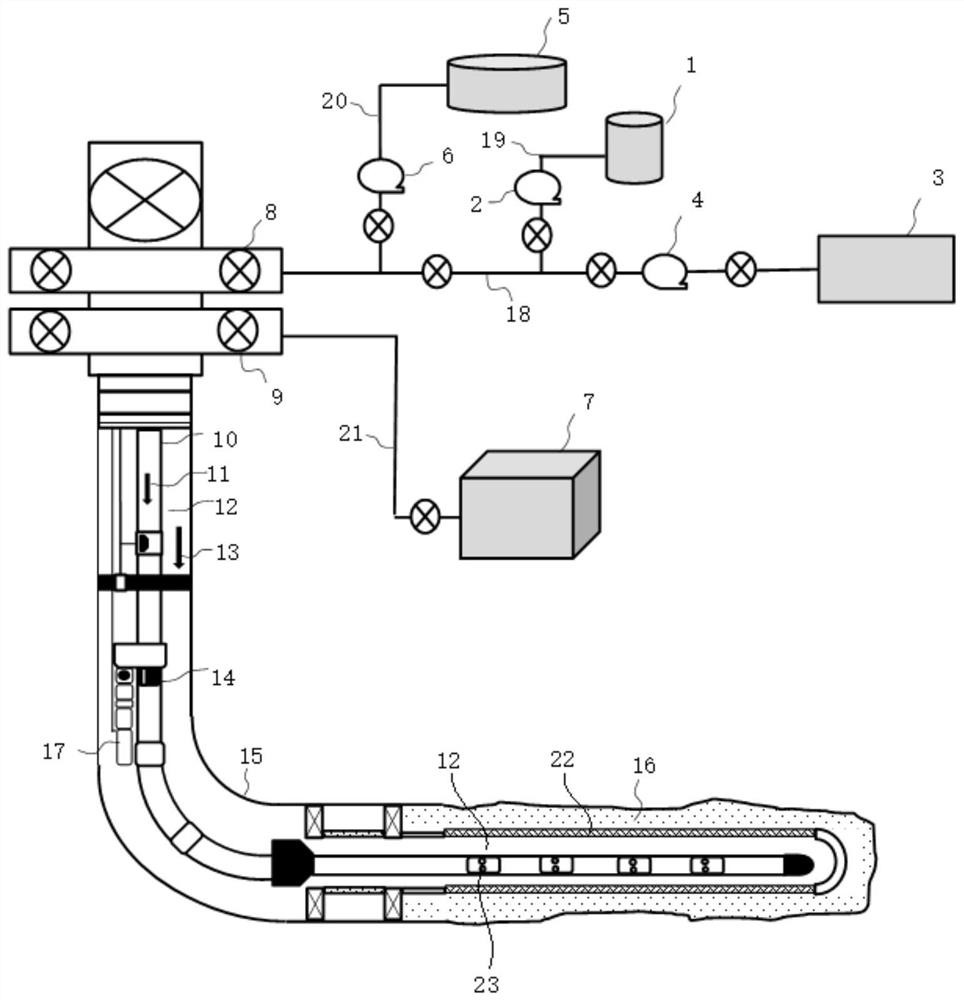

[0041] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0042] as attached figure 1 As shown in Fig. 1, a thermal compound throughput enhancement system for low-yield heavy oil cold production wells in the sea, the system includes a wellhead Christmas tree and an electric pump production string, and the tubing wing valve 8 and casing wing valve 9 are installed on the wellhead Christmas tree, and the electric pump The production tubing string includes tubing 10, casing 15, screen 22, Y plug 14 and electric submersible pump 17, etc. An oil casing annulus 12 is formed between tubing 10 and casing 15 and between tubing 10 and screen 22. A plurality of liquid outlet holes 23 are arranged at intervals on the horizontal section of 10 .

[0043] The system also includes a hot water injection pipeline 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com