A kind of anti-rock burst and anti-jamming gas drilling bit

A gas drilling and anti-jamming technology, which is used in drilling equipment, drilling tools, earth-moving drilling, etc., can solve problems such as unfavorable removal of large cuttings, small inner holes, and can not meet the treatment of downhole rock blasting and well wall collapse accidents, etc. To prevent single water eye blockage, improve chip removal and cooling tooth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

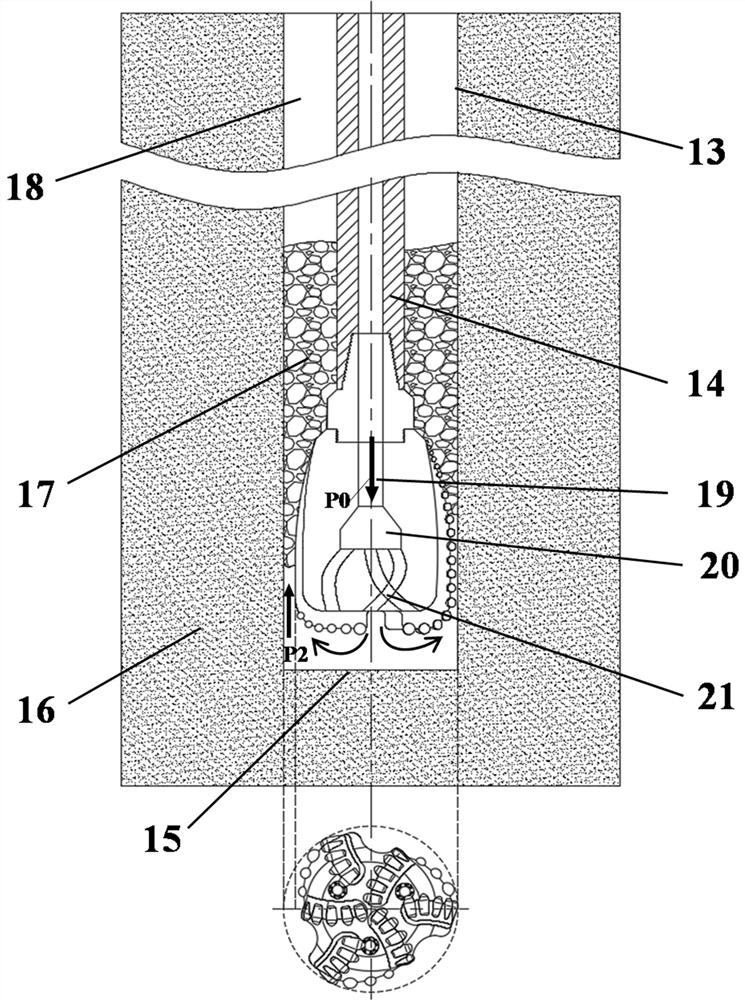

[0031] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0032] Such as Figure 1-4 Shown:

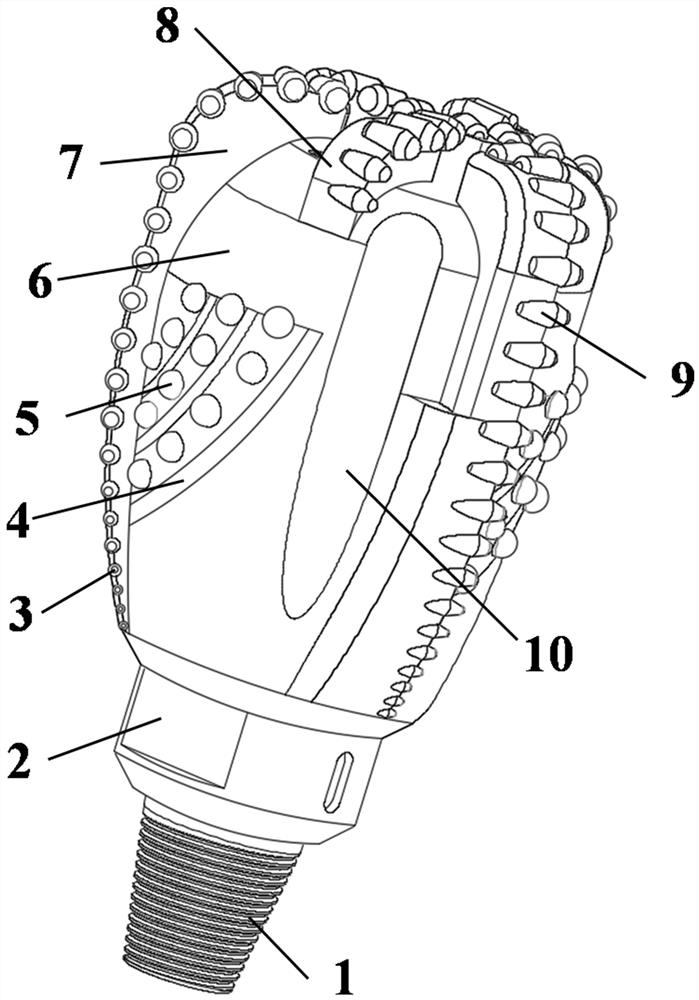

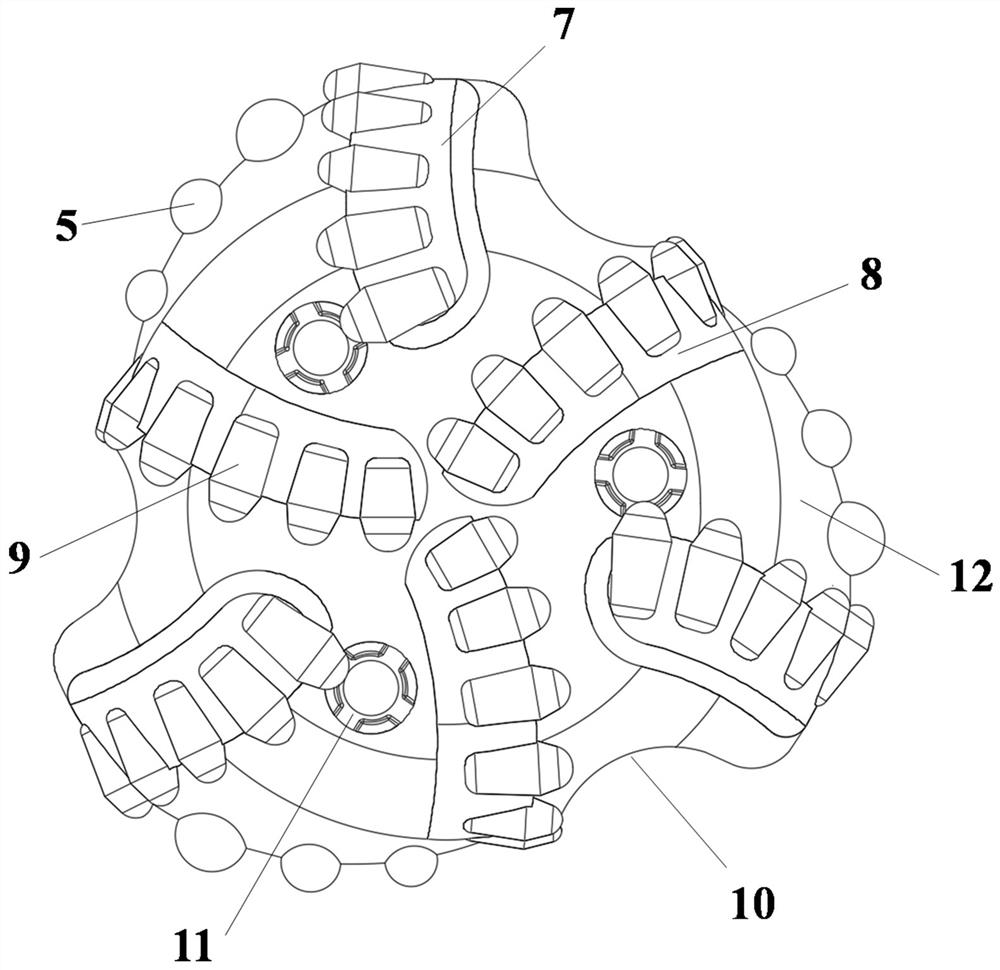

[0033] The present invention provides an anti-rockburst and anti-jamming gas drilling bit, comprising a threaded upper joint 1 and a drill bit body 6 installed on the threaded upper joint 1; wherein:

[0034] The drill bit body 6 is provided with a plurality of main blades 7, and a plurality of auxiliary blades 8 are arranged at the bottom thereof;

[0035] The main blade 7 and the auxiliary blade 8 are evenly distributed on the bit body 6 with mutual intervals;

[0036] A plurality of PDC cutting teeth 9 are provided on the end of the main blade 7 away from the threaded upper joint 1 and on the auxiliary blade 8;

[0037] A plurality of undercut cutting teeth 3 are also provided on the end of the main blade 7 close to the threaded upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com