Wet concrete feeding assistant vibrator and using method thereof

A vibrator and feeding technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of poor use of the screening machine, no complete solution to the problem, and the bottom shaft end not feeding into the pulp, etc. Effects of Internal Blockage Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

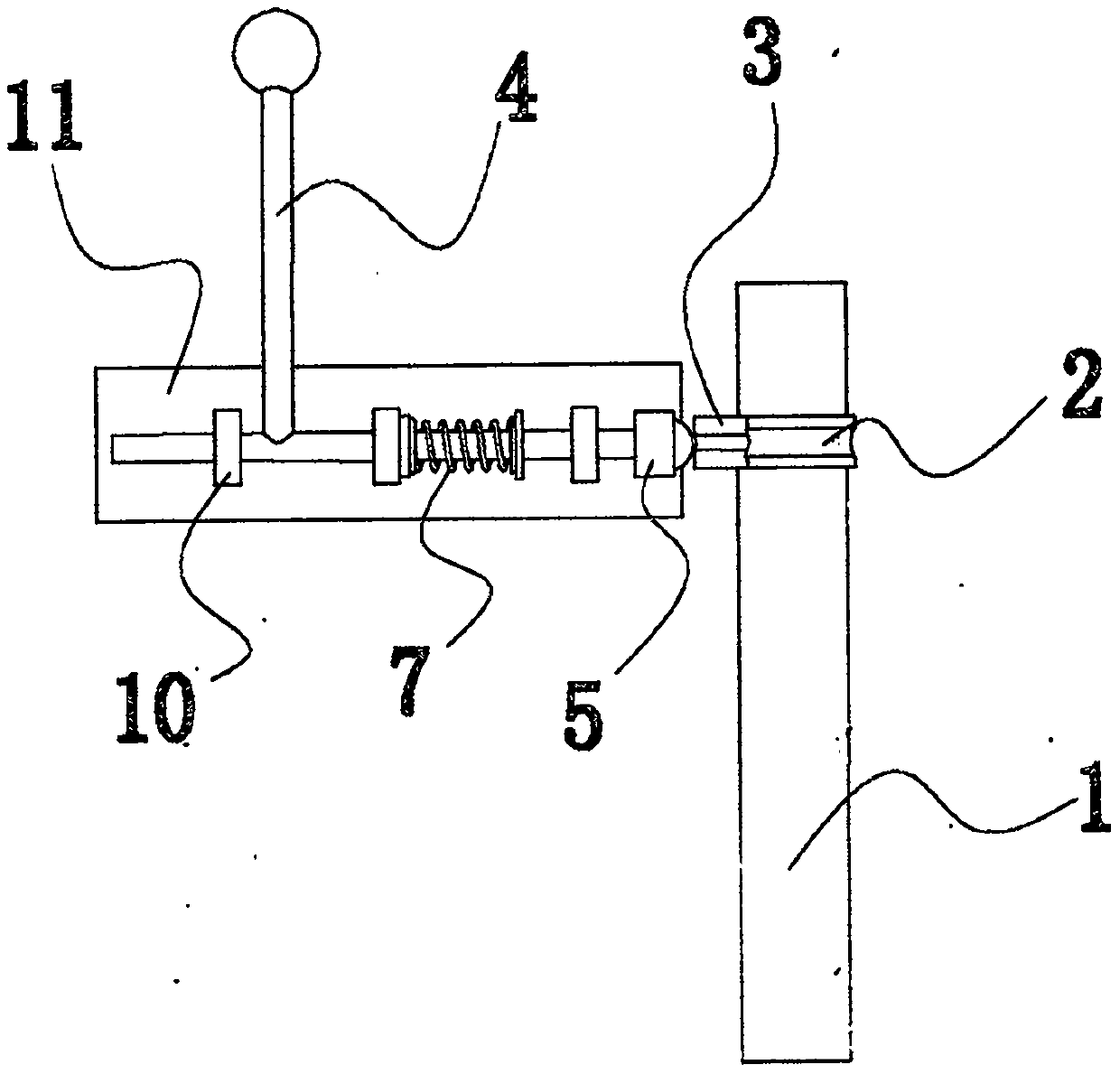

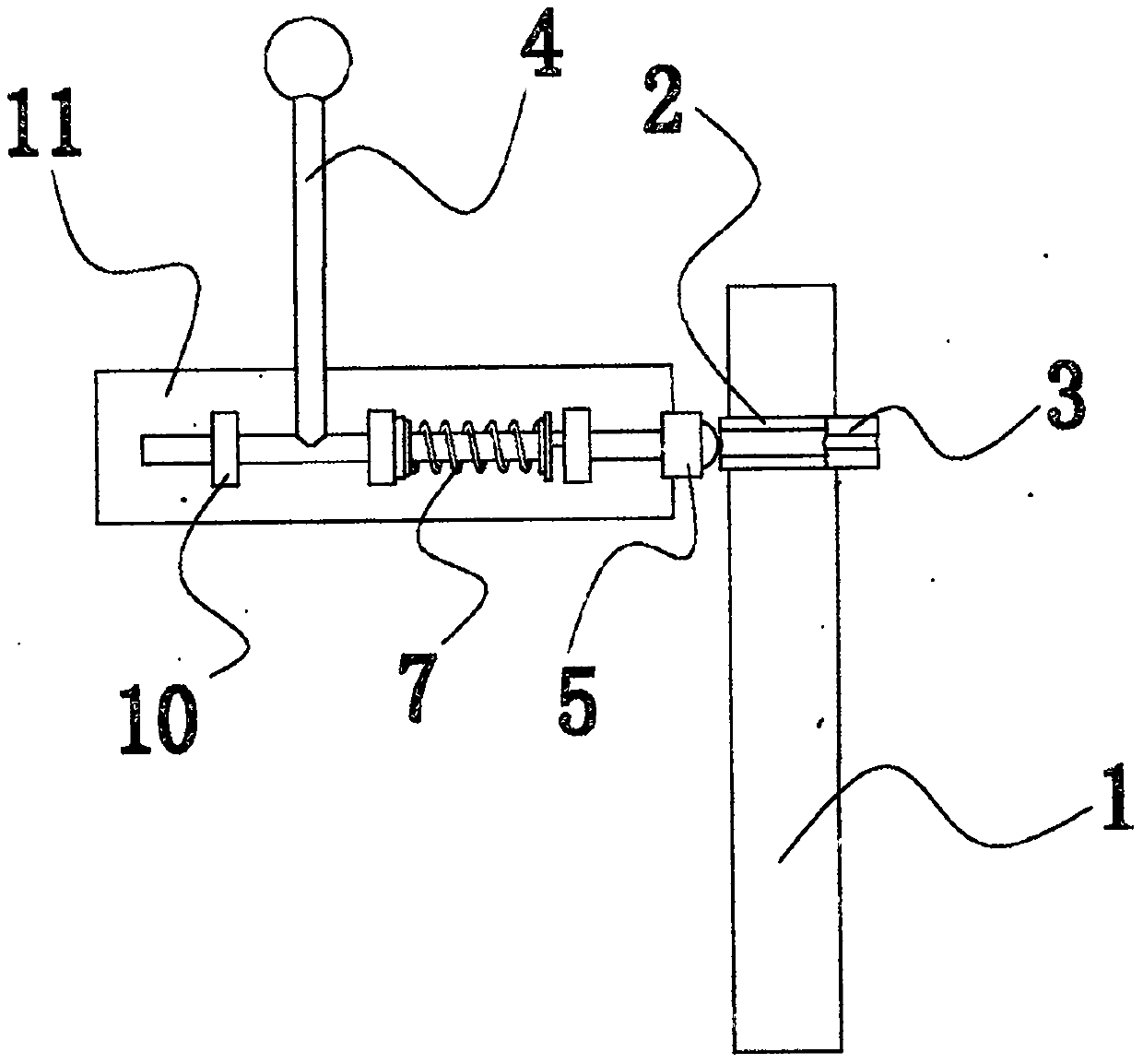

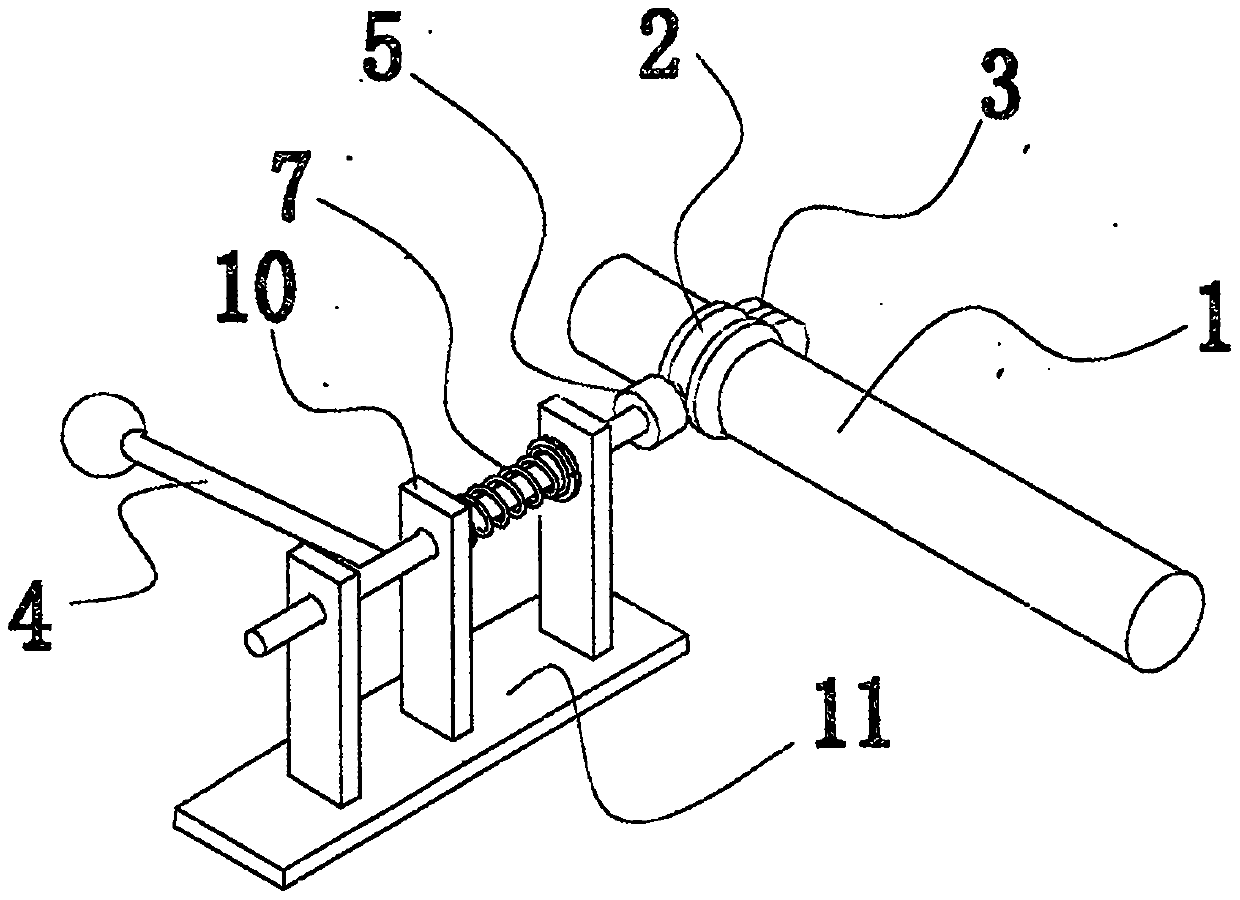

[0024] A wet-mix feed assist vibrator and method of use thereof, such as Figure 1-Figure 6 As shown, it includes 1-main shaft 1, 2-vibrating hammer mounting seat 2, 3-vibrating hammer 3, 4-vibrating rod 4, 5-rolling marble mounting seat 5, 6-rolling marble 6, 7-spring 7 , 8-spring base 8,9-spring top seat 9,10-vibrator mounting seat 10,11-base 11. It is characterized in that: a vibrator for assisting wet mixing feeding and its use method, characterized in that: the vibrating hammer 3 is installed on the main shaft 1 of the screening machine through the vibrating hammer mounting seat 2, and the vibrating rod 4 is installed through the vibrating rod mounting seat 10 On the top of the base 11, the spring base 8 is fixed on one side of the vibrating rod mounting seat 10 in the middle position, the spring 7 is installed on the vibrating rod 4, the bottom is close to the spring base 8, the top is close to the spring top seat 9, and the spring top Seat 9 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com