Ash collecting device of concrete pavement ash cleaner for enhancing negative pressure suction

A technology for concrete pavement and ash cleaning machine, which is applied in the direction of pavement cleaning, cleaning methods, construction, etc., can solve the problems of insufficient technical consideration, reduced cleaning effect, incomplete cleaning of residues, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

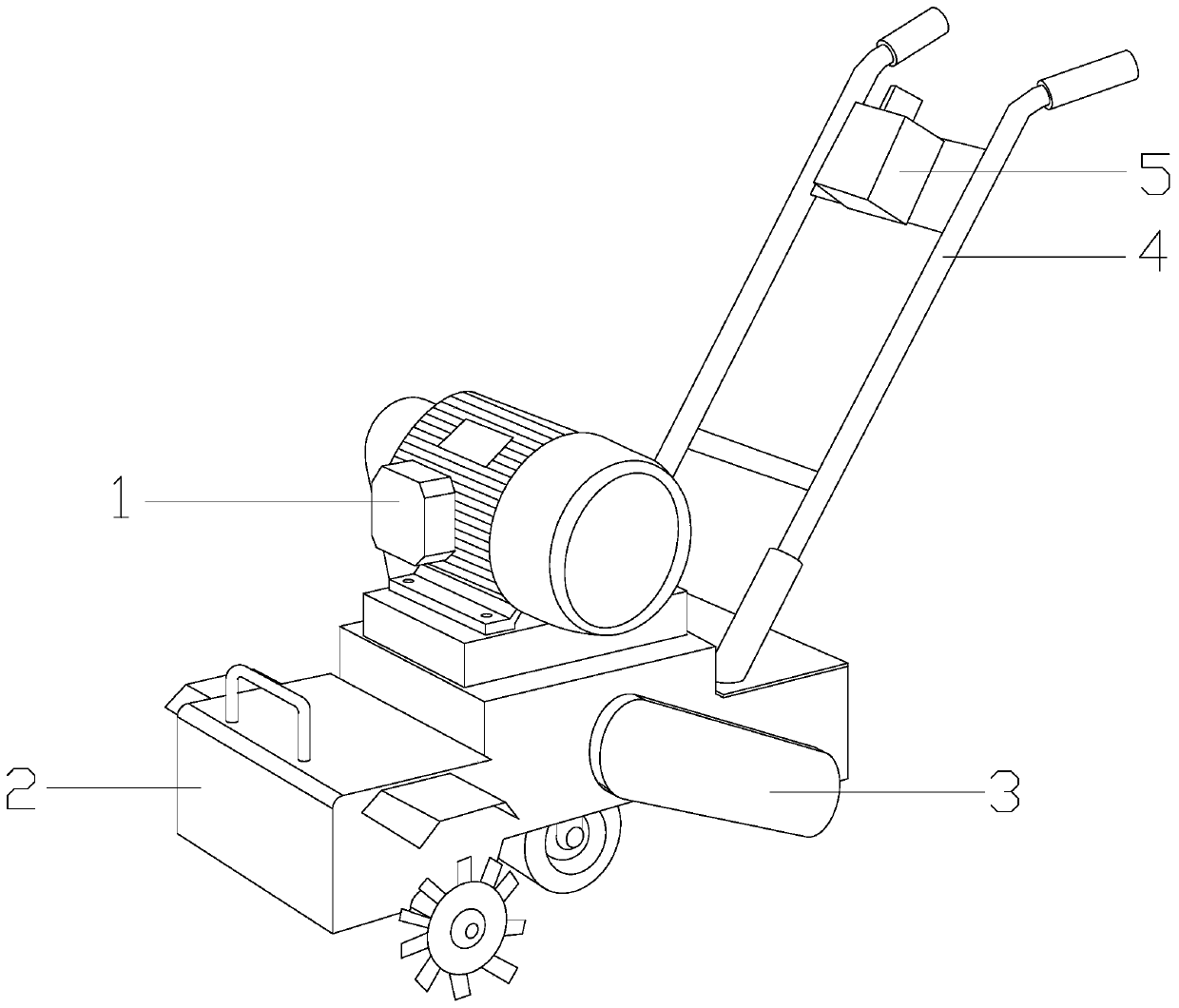

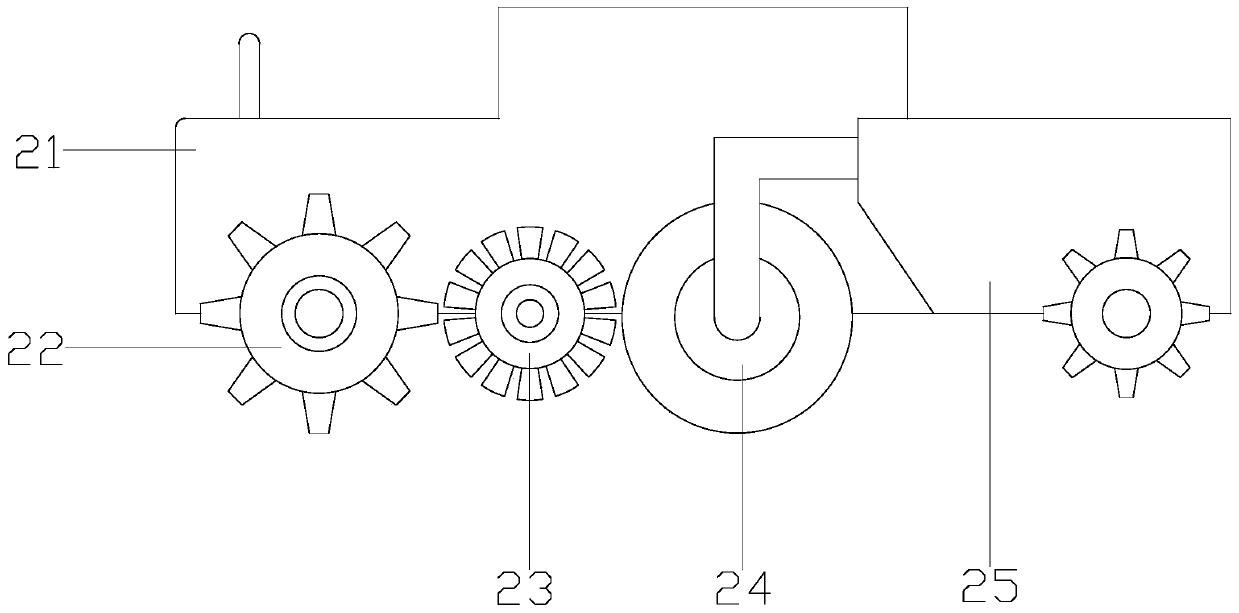

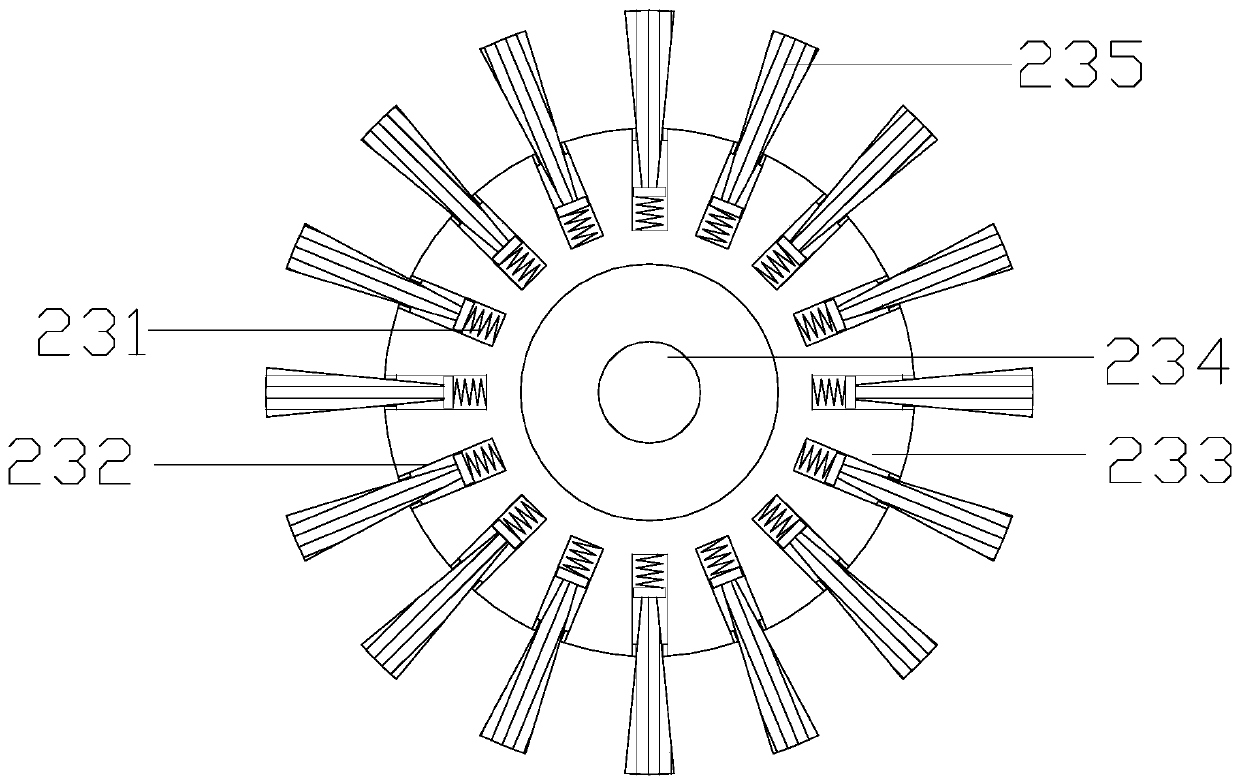

[0022] see Figure 1-Figure 2 , The present invention provides a dust collecting device for a concrete pavement cleaning machine with enhanced negative pressure suction. , the main body 2 of the cleaning machine is a convex structure and placed on the concrete floor, the driving motor 1 is located in the middle of the upper surface of the main body 2 of the cleaning machine and is connected with the main body 2 of the cleaning machine by bolts, the protective cover of the transmission chain 3. The back side is bolted to the right side of the main body 2 of the cleaning machine. The bottom of the handrail 4 of the cleaning machine is welded to the right end of the upper surface of the main body 2 of the cleaning machine. The power controller 5 is located on the left side of the handrail 4 of the cleaning machine. The main body 2 of the cleaning machine is composed of a cleaning machine shell 21, a concrete cleaning hob 22, a dust sweeping structure 23, a dust collecting moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com