Underground workshop rock anchor beam drilling positioning device and using method thereof

A technology of positioning device and underground workshop, applied in drilling equipment and methods, underground chambers, mining devices, etc., can solve problems such as insufficient drilling positioning, and achieve the effects of reducing labor intensity, saving labor, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

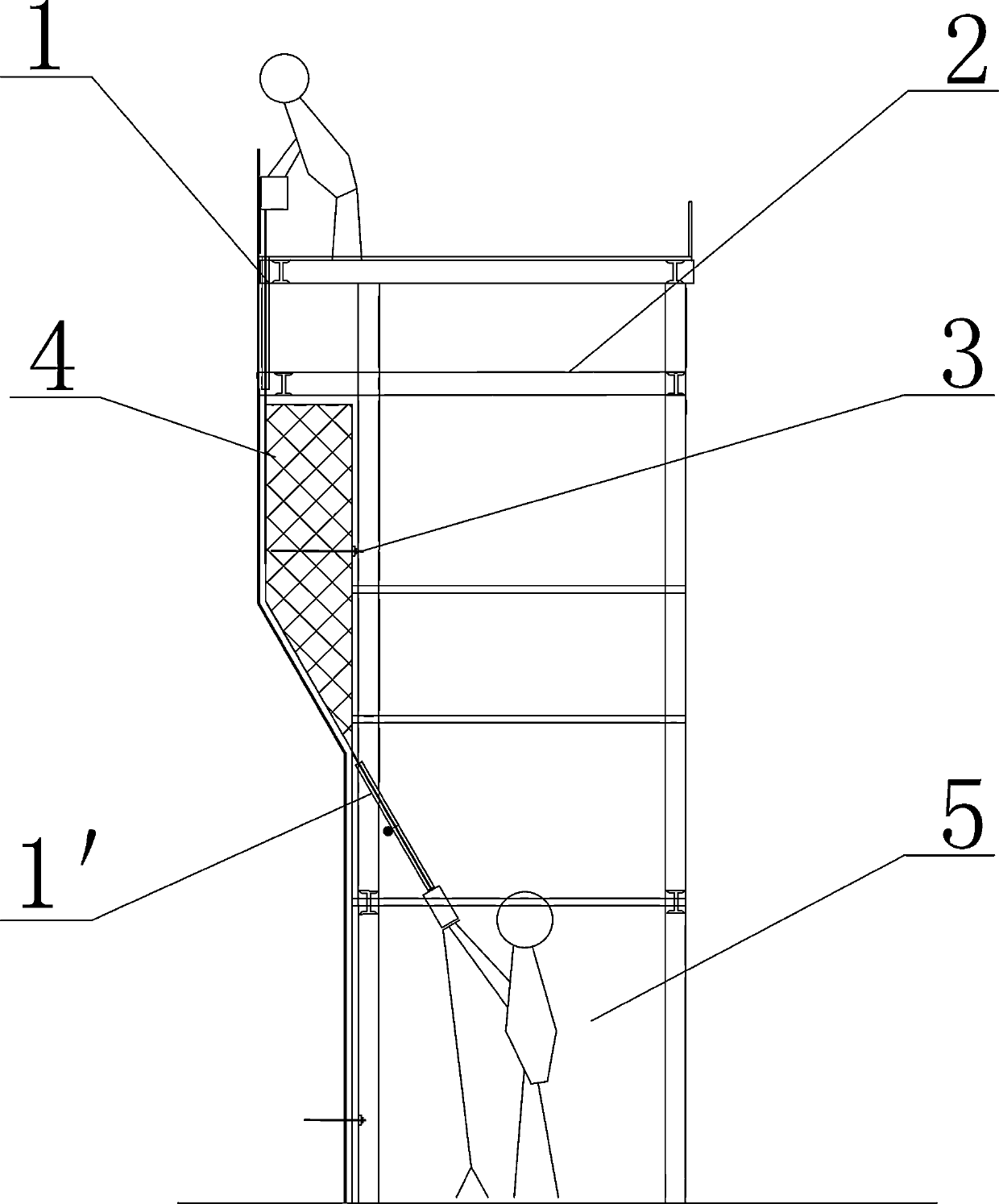

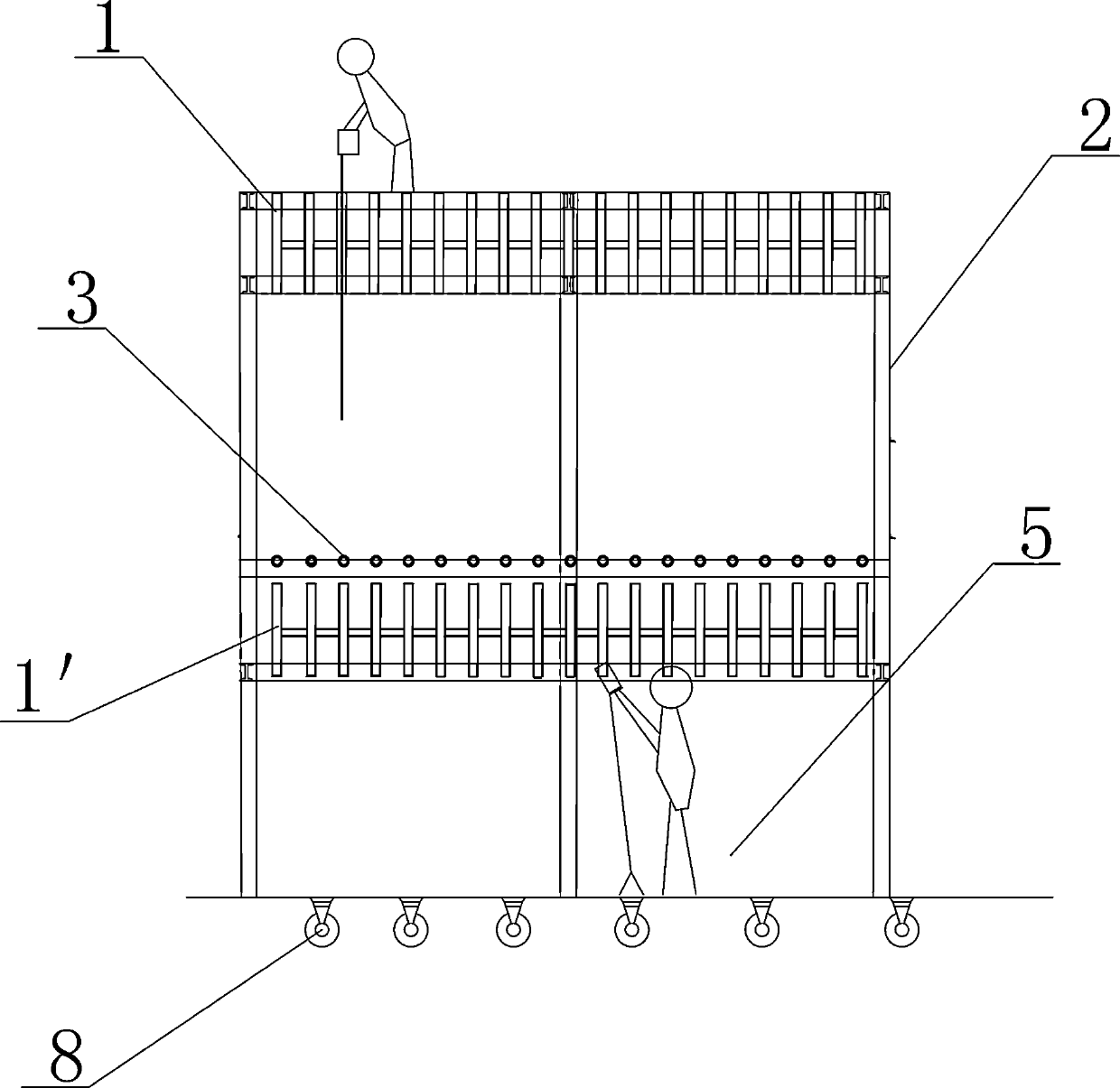

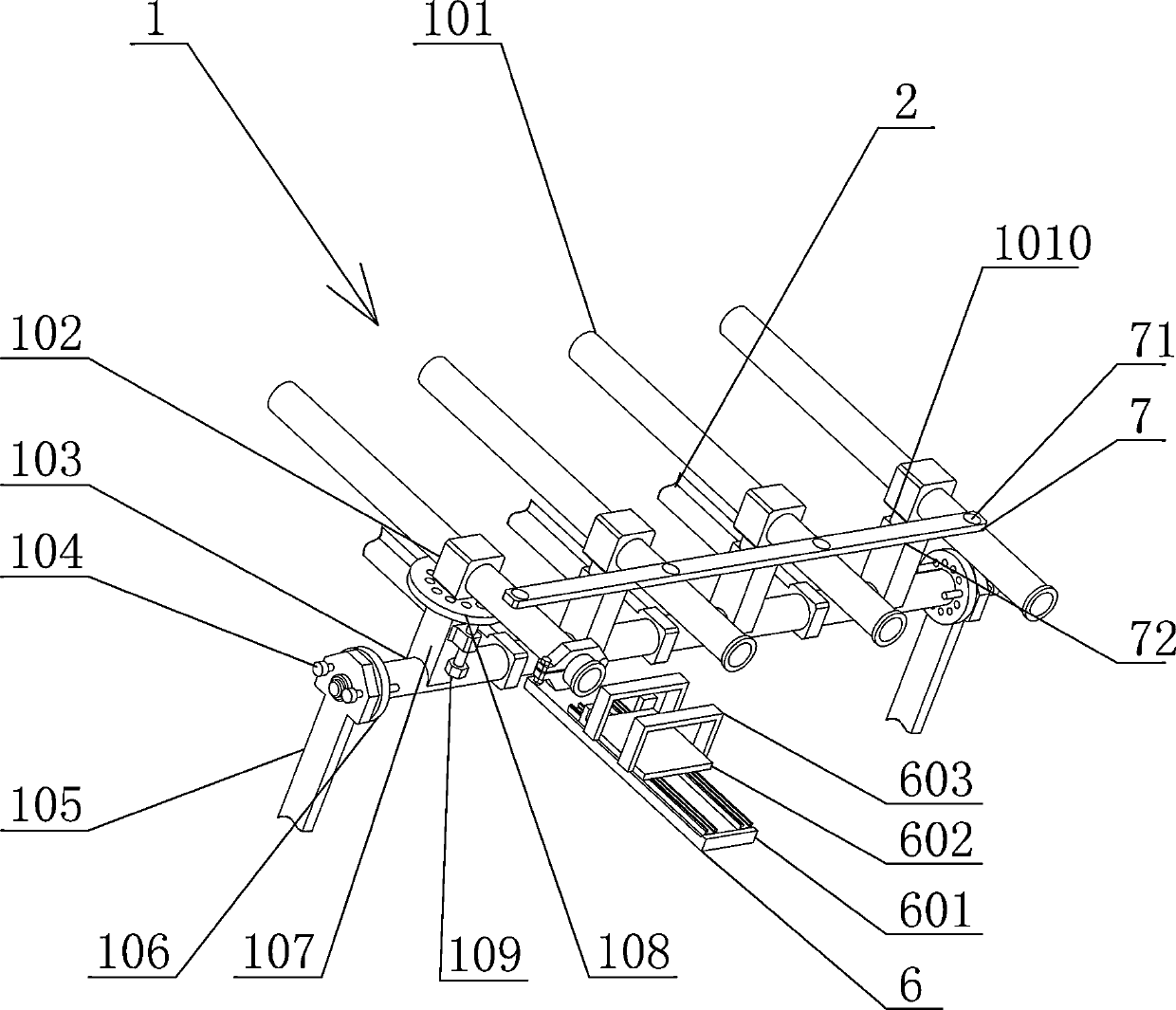

[0037] like Figures 1~6 As shown, an underground powerhouse rock anchor beam drilling positioning device includes a platform 2, and a hole positioning device is provided on the platform 2, and the hole positioning device is a plurality of side-by-side guide bushings 101, the plurality of side-by-side The guide casing 101 is connected by a synchronous connection device 7, and a drilling rig mounting frame 6 is arranged on the guide casing 101. With this structure, the mobile drilling positioning device is improved on the basis of the "sample frame method" positioning device. , First, a guide casing is added to ensure the drilling accuracy, which is beneficial to the effect of light explosion and the quality of the bolt. The function of multiple side-by-side guide casings 101 is that a drilling rig can be positioned in the side-by-side guide casings 101. When drilling, the guide casing 101 is connected through the synchronous connection device 7 to better synchronously adjust t...

Embodiment 2

[0048] Further illustrate in conjunction with embodiment 1, as Figures 1~6 As shown in the figure, the bench 2 is manufactured, and is manufactured in parts according to the design drawings in the manufacturing workshop. The components are bolted together and pre-assembled for testing. After the acceptance is passed, the parts are numbered. The bench 2 is installed and installed according to the measurement and positioning. After being accurately adjusted in place, the anchor bars are installed on the rock wall to fix the 3 and the bench 2 to be reliably connected to ensure stability. The guide casing 101 is installed and corrected, and the guide casing 101 is installed and corrected according to the drilling position measured and calibrated to ensure the accuracy of its positioning and guidance. For drilling operations, the drilling rig mounting frame 6 is used to drill along the guide casing. , in order to ensure the accuracy of drilling, the gantry 2 moves, after completin...

Embodiment 3

[0050] Further illustrate in conjunction with embodiment 1 and 2, as Figures 1~6 As shown, the platform 2 is installed to the position of the rock platform 4, and after being accurately adjusted in place, the anchor bars 3 are installed on the rock wall of the rock platform 4, which are reliably connected with the platform 4 to ensure stability, and the hole positioning device is installed. Install the hole positioning device at the corresponding position of the drilled hole in the rock table 4, fix the support frame 105 on the table 2, and hinge the connecting shaft with the horizontal frame of the table 2. After the installation of the hole positioning device is completed, adjust the hole positioning device. The guide sleeve 101 is adjusted according to the measured position, angle and direction of the borehole, and the first angle plate 106 is adjusted to drive the angle of the guide sleeve 101 up and down. The angle is fixed in the hole. After adjusting the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com