Rock core sampling drilling machine capable of avoiding friction overheating

A technology for core sampling and drilling rigs, which is applied in the direction of rotary drilling rigs, drill pipes, drill pipes, etc., can solve the problems of affecting the service life of drill pipes, wasting labor productivity, and reducing the ability to resist extrusion, so as to reduce labor costs, The effect of saving water and enhancing the ability to resist stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

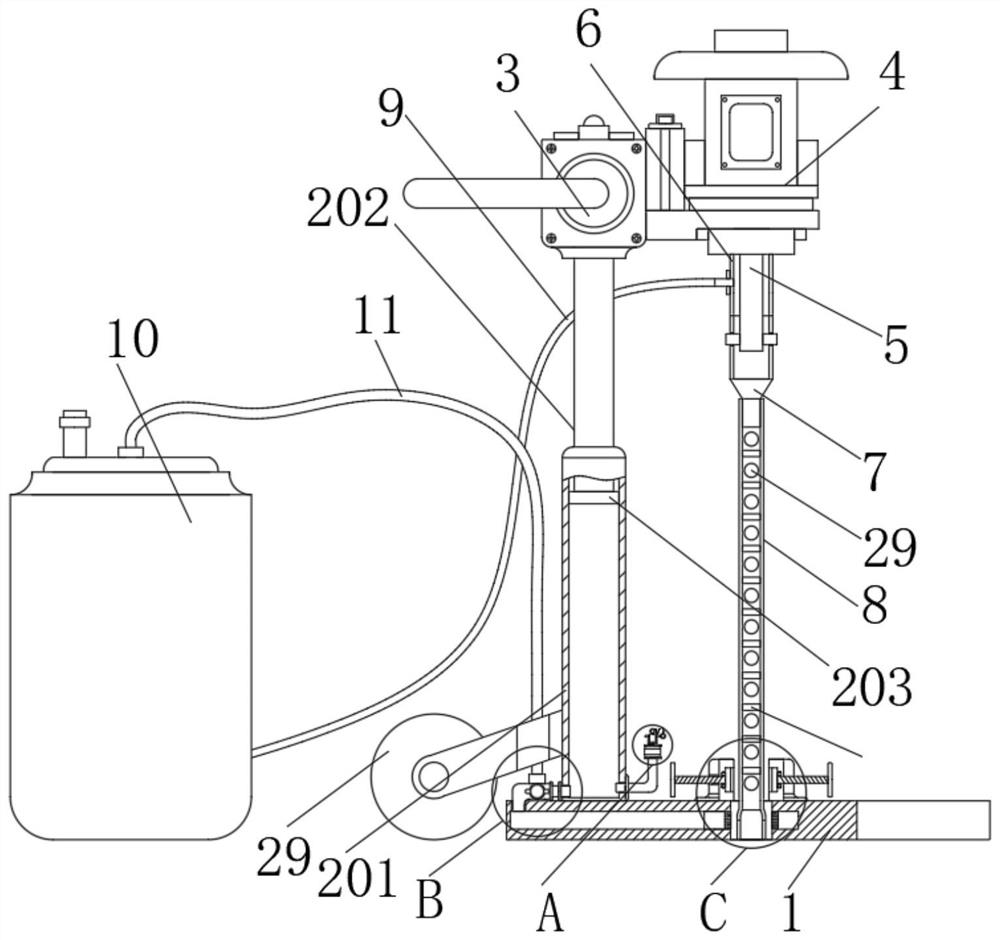

[0040] see figure 1 , figure 2 and Figure 5 The core sampling drilling rig for avoiding frictional overheating of the present invention includes a base 1 and a motor 4, the top of the base 1 is fixedly mounted with a pneumatic assembly 2, the top of the pneumatic assembly 2 is fixedly connected with a receiving plate 3, and one end of the pneumatic assembly 2 is fixedly connected with a The air outlet pipe 11, the end of the air outlet pipe 11 away from the pneumatic component 2 is fixedly connected to the water storage cylinder 10, the bottom of the water storage cylinder 10 is fixedly connected to the water inlet pipe 9, the motor 4 is fixedly installed on the top of the receiving plate 3, and the output end of the bottom of the motor 4 is fixed Connected with a rotating shaft 5, the bottom of the rotating shaft 5 is fixedly equipped with a casing 7, the bottom of the casing 7 is threadedly connected with a drill pipe 8, and the inner wall of the drill pipe 8 is fixedly con...

Embodiment 2

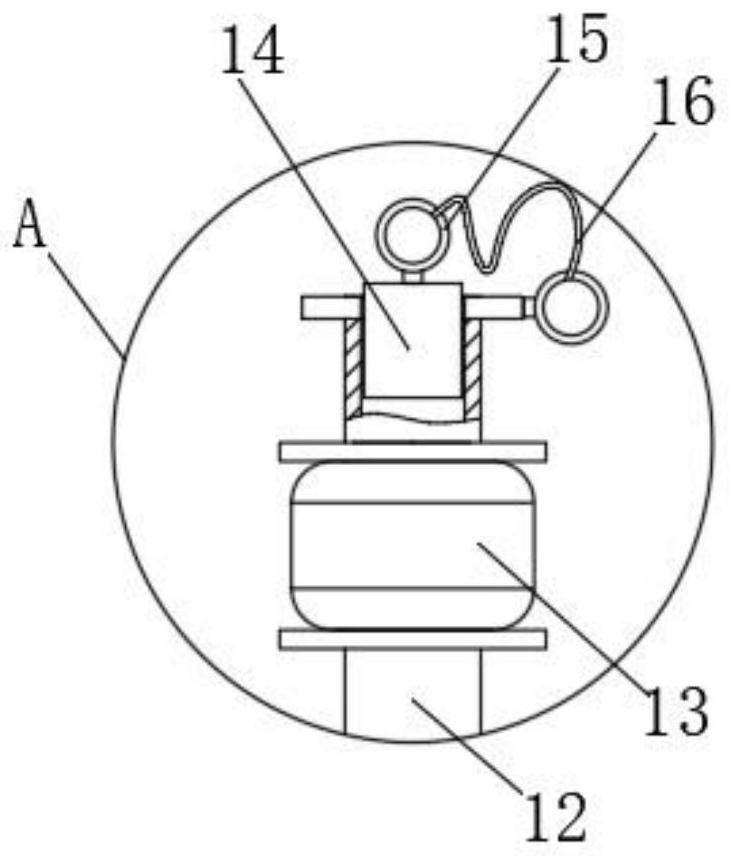

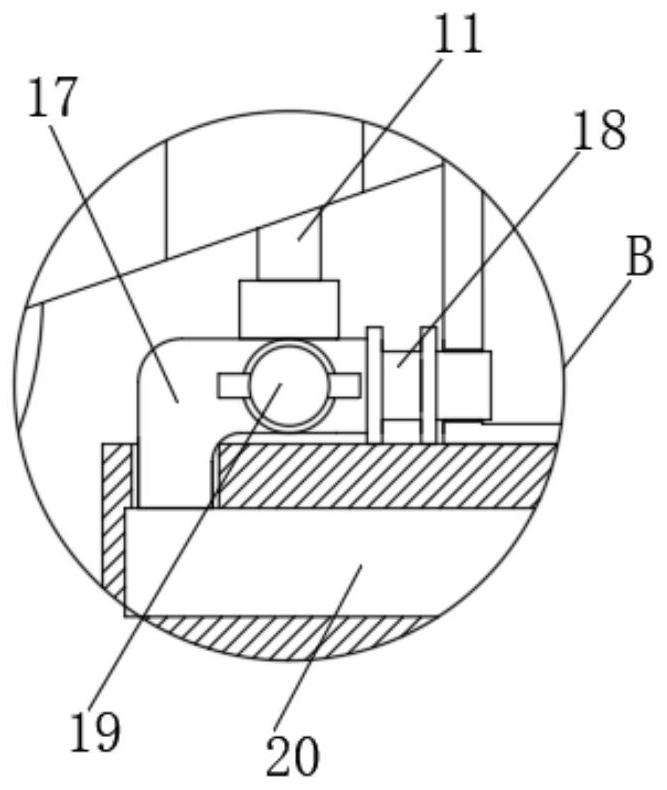

[0043] see figure 1 , image 3 and Figure 5 The end of the intake pipe 12 away from the gas cylinder 201 is movably connected with a rubber plug 14, one side of the rubber plug 14 and the side wall of the gas cylinder 201 are fixedly connected with a circular ring 15, and a connecting belt 16 is fixedly connected between the two circular rings 15, One side of the bottom of the gas cylinder 201 is fixedly connected with a three-way pipe 17 communicating with the inside of the gas cylinder 201. A three-way valve 19 is installed on the surface of the three-way pipe 17, and a second one-way valve is fixedly installed on the side of the three-way pipe 17 close to the gas cylinder 201. A cavity 20 is opened inside the valve 18 and the base 1, and the end of the tee pipe 17 away from the gas cylinder 201 runs through the cavity 20, and the inside of the cavity 20 is penetrated with a ventilating groove 21, and the inner wall of the ventilating groove 21 is uniformly provided with v...

Embodiment 3

[0046] see figure 1 , Figure 4 and Figure 6 , the top surface of the base 1 is fixedly connected with a fixed block 23, the side wall of the fixed block 23 is threadedly connected with a threaded rod 24, one end of the threaded rod 24 is fixedly connected with a fastening block 25, and one side of the fastening block 25 is fixedly connected with a rubber Block 26, the top surface of base 1 is provided with perforation 27, the top view surface of fixed block 23 and fastening block 25 are all designed to be semi-arc, the side of base 1 is fixedly connected with pedal 28, and the top surface of pedal 28 is designed to protrude , the side of the gas cylinder 201 is fixedly equipped with a roller 29 through a connecting rod, a fixed mount and a rotating rod.

[0047] The difference from Embodiment 2 is that the setting of the fixing block 23 and the threaded rod 24 can be used to limit and fix the drill pipe 8, and the tightening block 25 is driven to clamp and fix the drill pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com