Liquid-cooling adjusting device and method of automobile power battery

A technology for automotive power batteries and regulating devices, which is applied in the direction of secondary batteries, battery temperature control, circuits, etc., can solve the problems that the temperature consistency of battery cells cannot be guaranteed, and the cooling effect of each battery is inconsistent, so as to achieve flow balance and temperature control. Stable and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

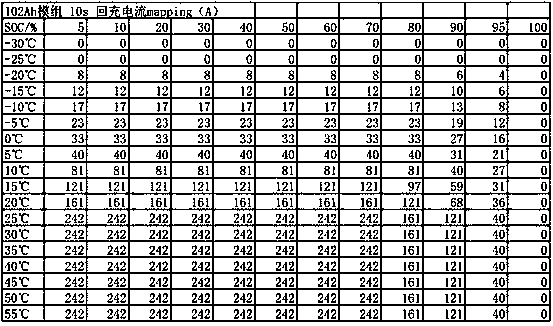

[0025] The discharge capacity curve and charge curve of a battery at different temperatures are shown in Table 1:

[0026] Table 1. The discharge capacity curve and charge curve of a battery at different temperatures

[0027]

[0028] From the table above, it can be obtained that the discharge and charge capabilities of the cells at different temperatures are different, so it is very important to ensure the consistency of the cell temperature during series use.

[0029] The traditional power battery water cooling system usually adopts a parallel connection, and the outlet pipe is connected to the battery cell through the connecting pipe, and the water inlet pipe is connected to the battery cell through the connecting pipe, but the inner diameter of the connecting pipe is the same. The disadvantage of this design is the flow distribution uneven.

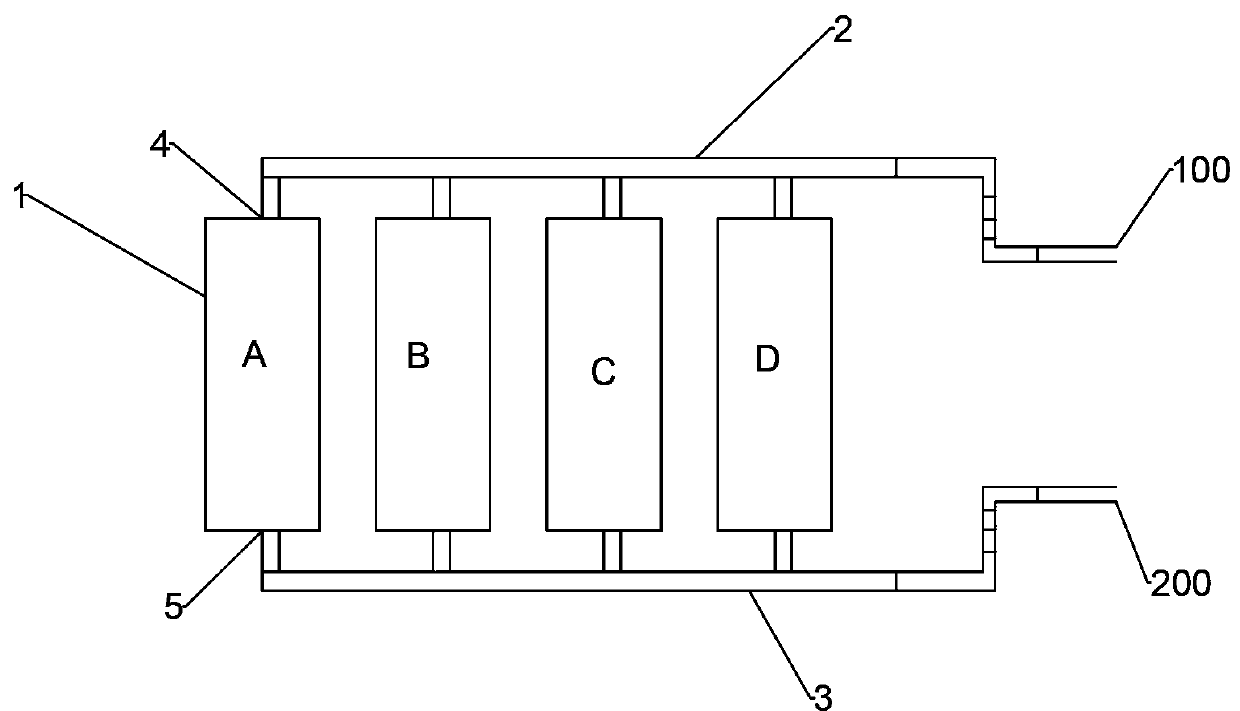

[0030] Such as Figure 1-2 As shown, a liquid cooling adjustment device for an automobile power battery includes a plurality of...

Embodiment 2

[0050] Based on embodiment 1, the difference from embodiment 1 is:

[0051] The inner diameters of the water inlet regulating valve 4 and the water outlet regulating valve 5 connected to the same battery cell 1 are the same. The water inlet regulating valve 4 and the water outlet regulating valve 5 connected to the same battery cell 1 are mirror-symmetrically arranged with respect to the center line of the battery cell 1 .

[0052] Such a design further ensures that the flow rate of the cooling fluid on the same battery cell 1 is consistent.

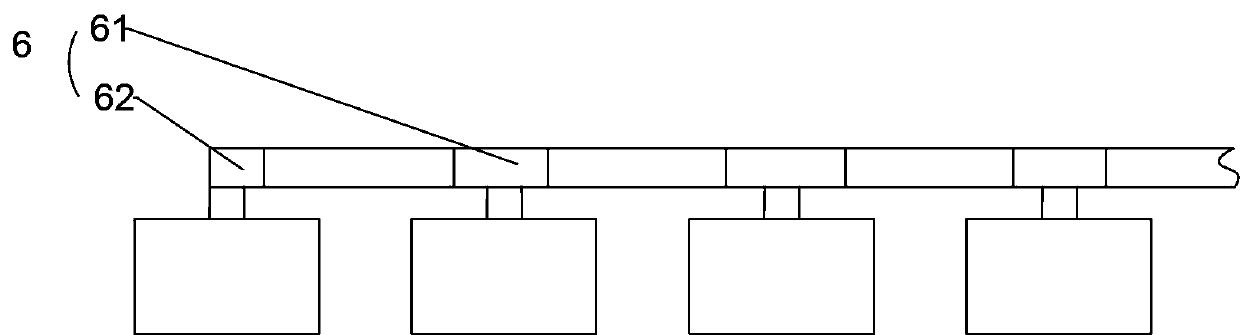

[0053] The water inlet regulating valve 4 is connected to the liquid cooling water inlet pipe 2 through a connecting device 6 , and the water outlet regulating valve 5 is connected to the liquid cooling water inlet pipe 2 through a connecting device 6 .

[0054] The connection device 6 includes a T-shaped end connector 61 for connecting the liquid-cooled outlet pipe 3 or the end portion of the outlet regulating valve 5 and a T-shaped en...

Embodiment 3

[0056] A liquid cooling adjustment method for an automotive power battery, comprising:

[0057] The coolant is cooled from the liquid-cooled water inlet pipe 2 through the water inlet regulating valve 4 to cool down a plurality of side-by-side battery cells 1, and then the coolant is discharged from the liquid-cooled water outlet pipe 3 through the water outlet regulating valve 5;

[0058] Wherein, the closer the water inlet regulating valve 4 is to the water inlet 100 in the water inlet direction, the larger its inner diameter; the closer the water outlet regulating valve 5 is to the water outlet 200 in the water outlet direction, the larger its inner diameter.

[0059] The inner diameter lengths of the water inlet regulating valve 4 and the water outlet regulating valve 5 are calculated according to pipeline resistance loss, fluid impedance and flow rate.

[0060] In this embodiment, the water inlet pipe 2, the water outlet pipe 3 are connected to the battery cell 1 at four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com