Magnetic levitation positioner

A technology of magnetic levitation and locator, which is applied in the direction of holding devices using magnetic attraction or thrust, electric traction, electric vehicles, etc. It can solve the problems of high manufacturing cost, heavy structure weight, and waste of power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

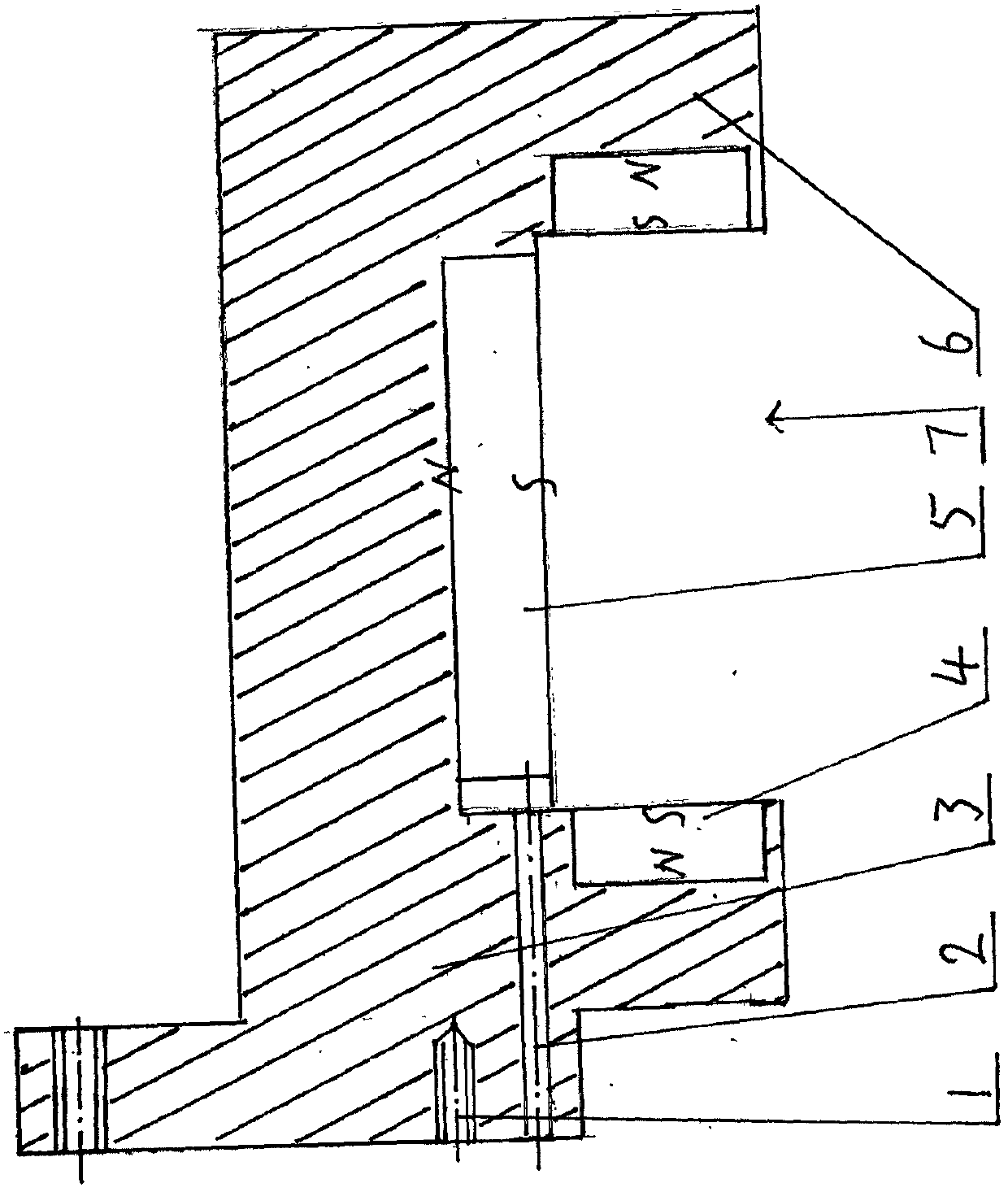

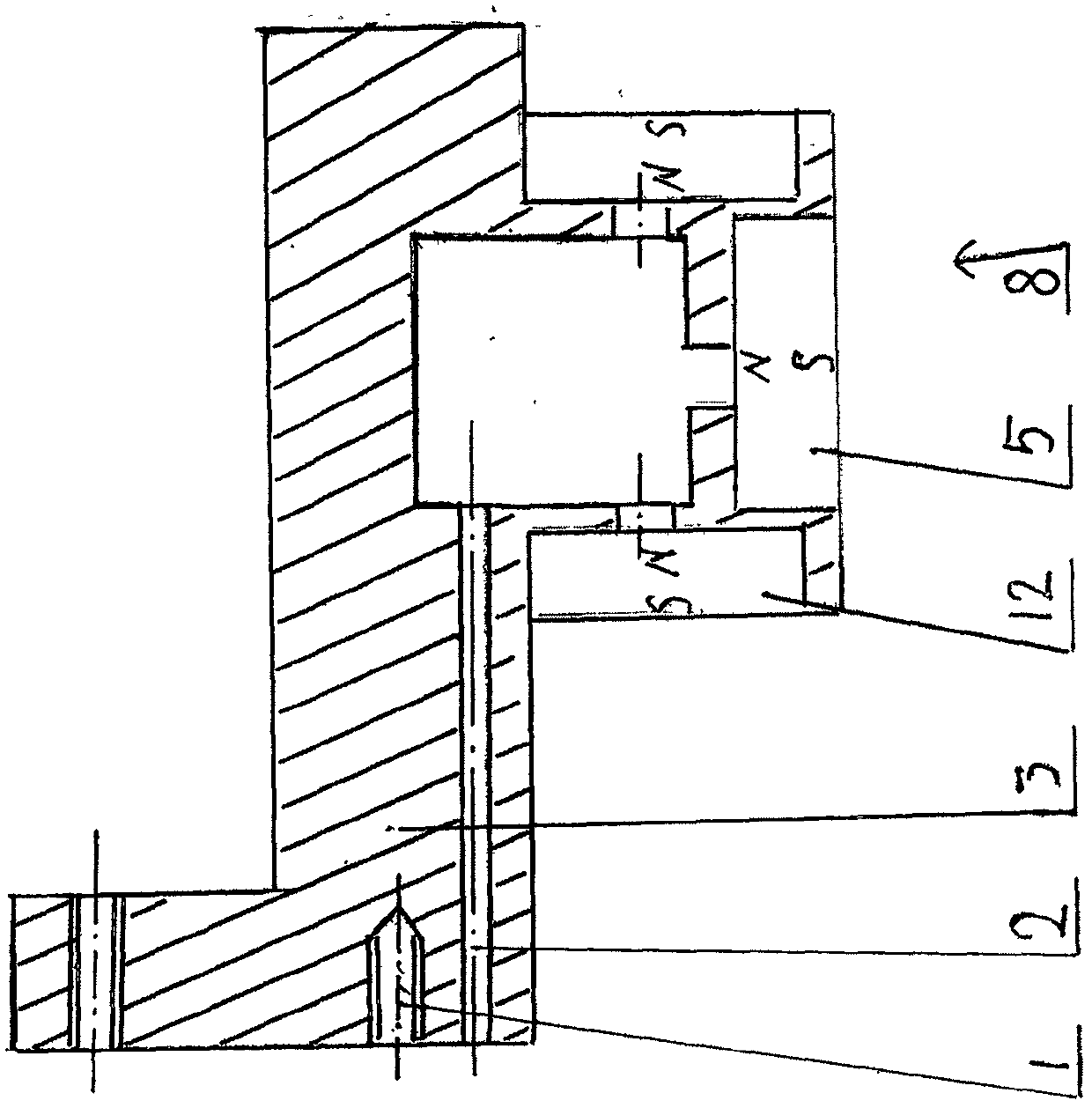

[0086] A magnetic levitation locator 3, such as Figure 1-Figure 2 As shown, the magnetic levitation locator 3 of the first embodiment of the present invention, the magnetic levitation locator 3 of the present invention is a device that applies the weight of the vehicle to the crawler belt through a magnetic field to move, figure 1 The positioning magnetic groove 7 is integrally or connected and formed on the magnetic levitation locator 3, and the gliding magnetic field 5 (S / N) is integrally or connected and formed on the positioning magnetic groove 7, and the positioning magnetic groove 7 The two sides of the magnetic levitation locator 3 adopt the magnetic levitation technology and are used for the wheel type by means of non-contact and frictionless magnetic levitation transmission. or crawler-type transportation tools; the magnetic levitation locator 3 of the present invention is fixedly connected with the vehicle movement tools through the bracket, the screw hole 1, and th...

Embodiment approach 2

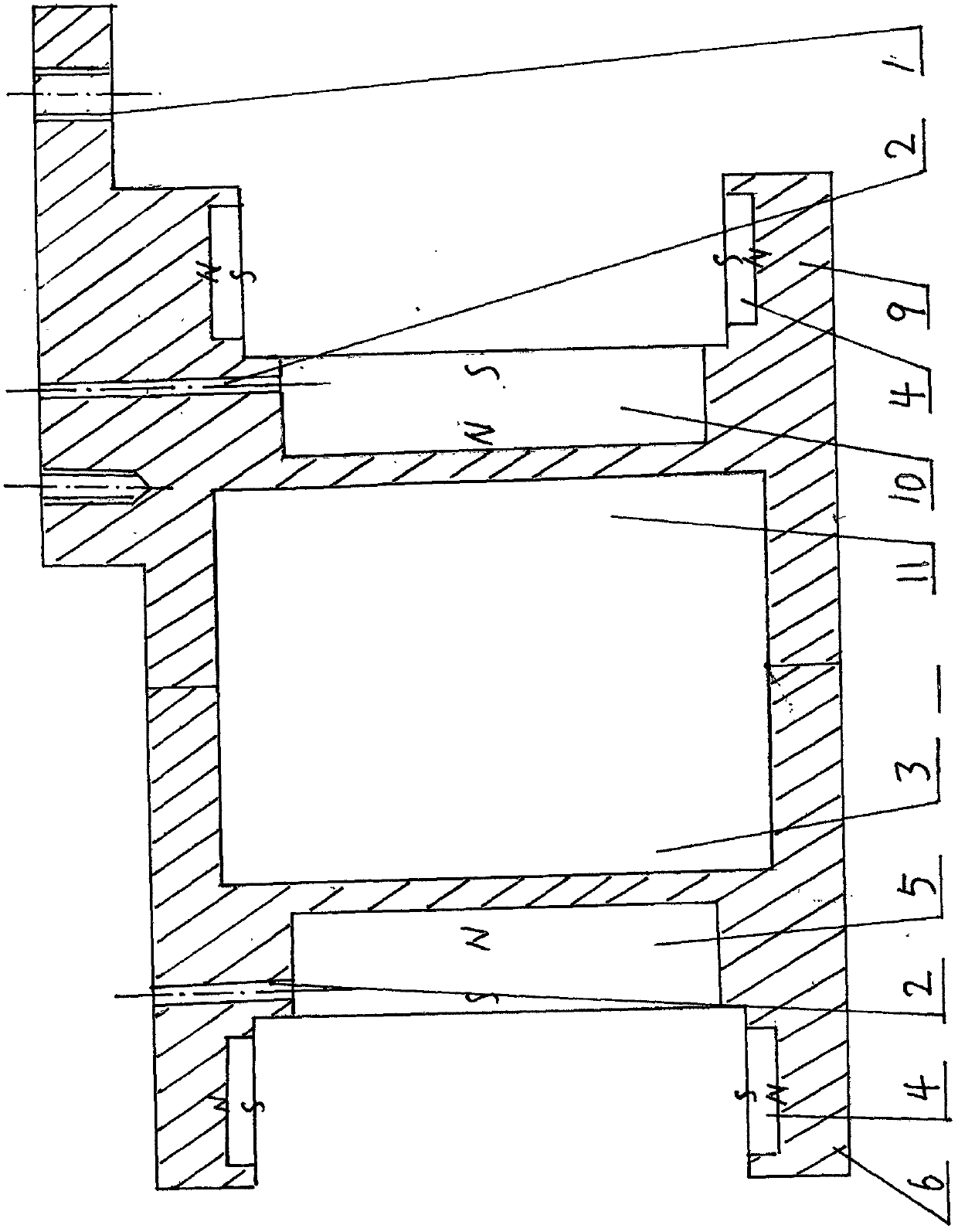

[0100] A magnetic levitation locator 3, such as Figure 3-Figure 4 As shown, the magnetic levitation locator 3 of the first embodiment of the present invention, the magnetic levitation locator 3 of the present invention is a device that applies the weight of the vehicle to the crawler belt through a magnetic field to move, and the magnetic levitation locator 3 is integrated or connected And form the positioning magnetic ridge 8 integrally, the gliding magnetic field 5 (S / N) is integrally or connected and formed on the positioning magnetic ridge 8, and the two sides of the positioning magnetic ridge 8 are integrally or connected and formed as one The belt positioning magnetic field 4 (S / N) is arranged to form a magnetic force wall, and the magnetic levitation locator 3 adopts the magnetic levitation technology, and is used on wheeled or crawler-type transportation vehicles by means of non-contact and frictionless magnetic levitation transmission work; The magnetic levitation lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com