Liquid immersion micro-channel measurement device and measurement method which are based on trapezoidal incident structure prism incident-type silicon

A measuring device and micro-channel technology, which is applied in the direction of measuring devices, scattering characteristics measurement, chemical instruments and methods, etc., can solve the problems of low measurement sensitivity, difficult separation, measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

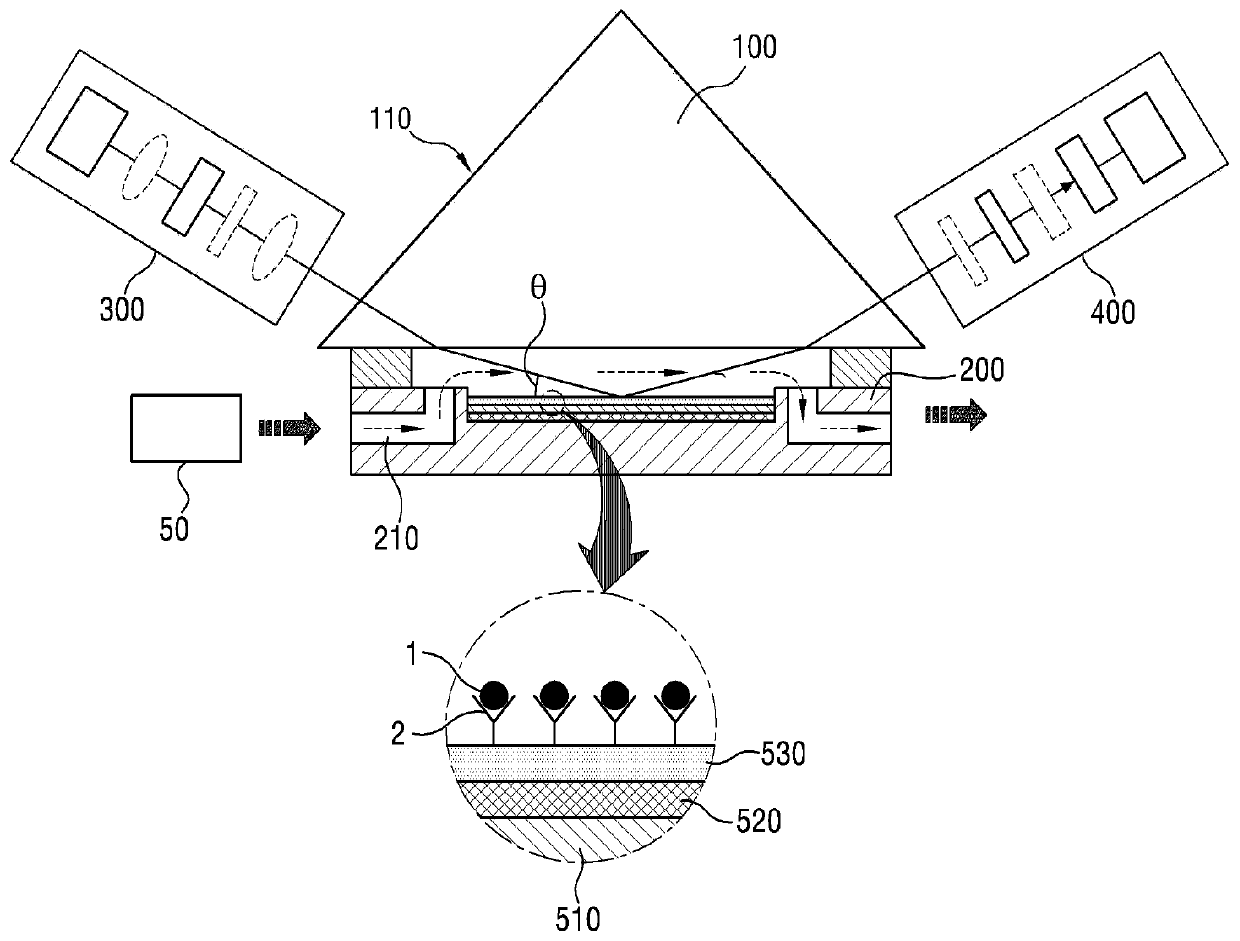

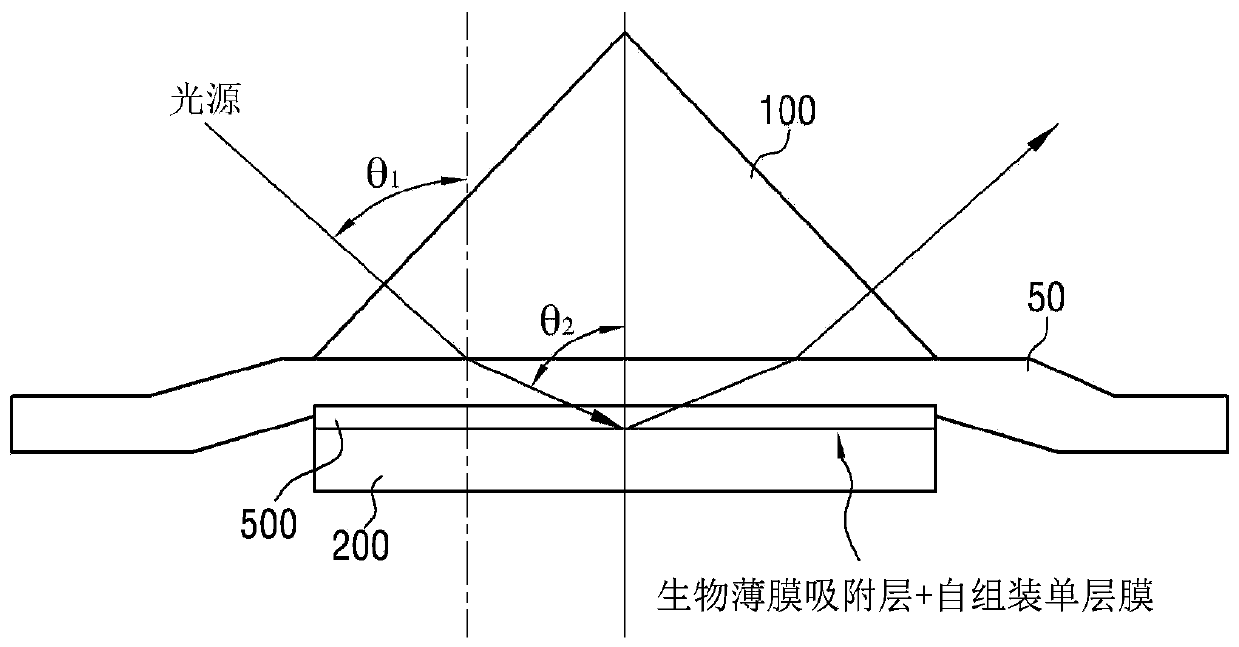

[0118] FIG. 10 is a diagram illustrating a path of polarized incident light 10 in a liquid immersion microchannel measurement device based on trapezoidal incident structure prism incident type silicon according to an exemplary embodiment of the present invention.

[0119] in particular, Figure 10a An example of a silicon-based liquid-immersion microchannel measurement device comprising a trapezoidal entrance structured prism formed from BK7 is illustrated, and Figure 10b An example of a silicon-based liquid-immersion microchannel measurement device including a trapezoidal incident structure prism formed of SF10 is illustrated.

[0120] In the prior art, there is a problem in that the measurement range of different angles according to the change of the refractive index is limited.

[0121] However, as shown in FIG. 10 , the silicon-based liquid immersion microchannel measurement device comprising a trapezoidal incident structure prism according to an exemplary embodiment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com