Powder material screening depolymerization machine

A technology of powder material and sieve body, which is applied in the field of powder material sieving and agglomeration machine, can solve the problems of high power consumption, affecting the screening efficiency, not meeting energy saving and consumption reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

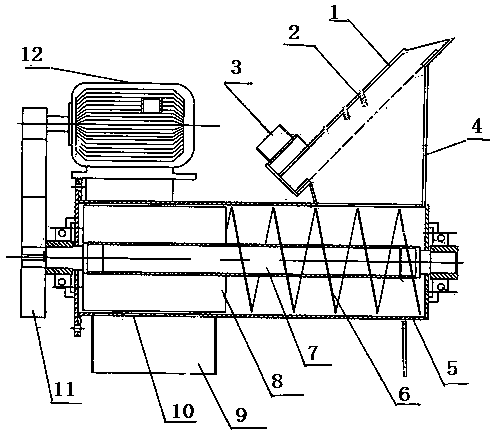

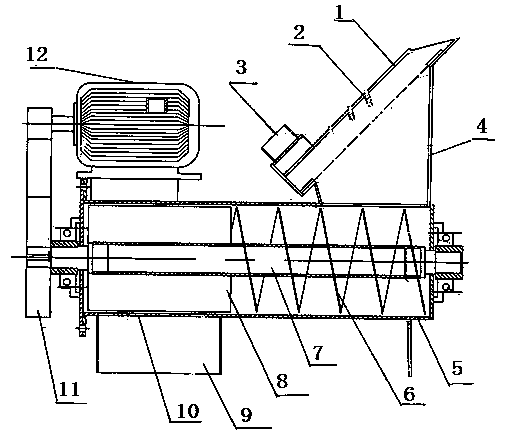

[0006] The embodiment is described in detail in conjunction with the accompanying drawings, which includes a sieve body 1 and a conveying hinge 5, and is characterized in that: on the horizontal axis 7 of the hinge, there are hinge blades installed between one end of the feed port and the discharge port 6. On the horizontal axis of the reamer, there are reamer blades 8 evenly distributed behind the reamer blades, which fit in the gap with the inner wall of the reamer, and a corresponding conical feed hopper is connected between the bottom surface of the screen body and the feed inlet of the reamer. 4. There is a material receiving pipe 9 connected downward at the opening of the reaming dragon, and uniformly distributed feeding holes 10 are arranged in the corresponding opening of the reaming dragon on the upper end of the receiving pipe. A motor 12 is installed at the rear, and a transmission mechanism 11 is connected between the motor shaft and the rear end of the horizontal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com