Can lid press

A technology for can lids and presses, which is applied to household appliances, hollow objects, and other household appliances, etc. It can solve the problems of inconvenient operation and complex structure of can lid presses, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

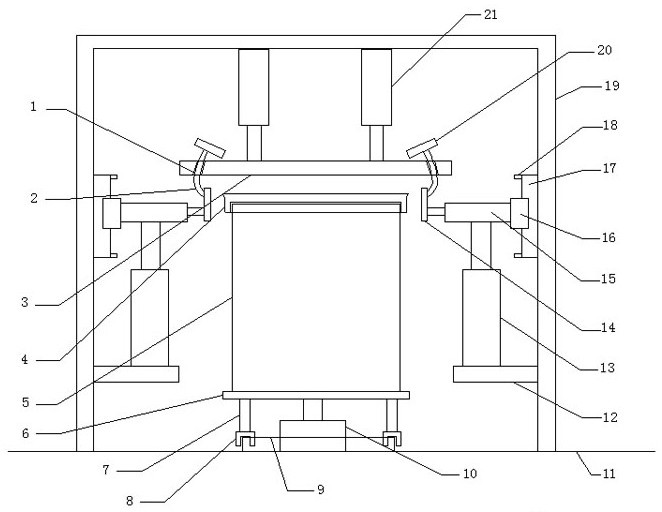

[0012] The can lid press machine of the present invention comprises a through hole 1, a plastic sheet 2, an upper pressing plate 3, a can 5 lid 4, a can 5, a turntable 6, a pillar 7, a first slider 8, a first slide rail 9, a motor 10, and a working Table 11, machine base 12, first cylinder 13, side pressure plate 14, second cylinder 15, second slider 16, second slide rail 17, limit block 18, frame 19, limit plate 20 and the third cylinder 21. The workbench 11 is provided with a motor 10, the output shaft of the motor 10 is provided with a turntable 6, the left and right sides of the turntable 6 are respectively provided with pillars 7, and the pillars 7 are arranged on the first slider 8, and the first slider 8 Set on the first slide rail 9, the first slide rail 9 is set on the workbench 11, the workbench 11 is provided with a frame 19, and the left and r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap